Kalina type industrial waste heat integrated recovery device

A recovery device and industrial waste heat technology, which is applied in the direction of steam engine devices, machines/engines, mechanical equipment, etc., can solve problems such as leakage, ammonia flammability, explosive toxicity, etc., to reduce exhaust gas temperature, efficient recovery, and avoid low-temperature corrosion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

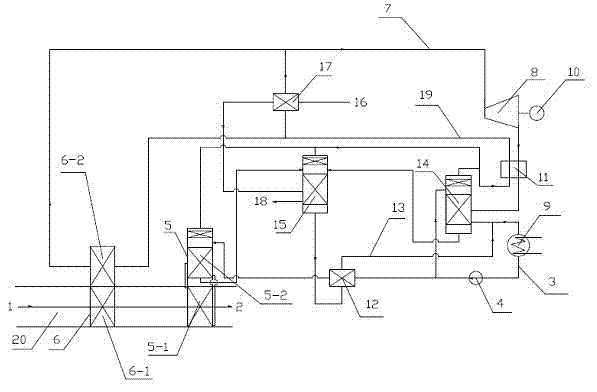

[0046] like figure 1 As shown, a Karina-type industrial waste heat integrated recovery device, the specific examples are as follows:

[0047] The high-temperature fluid 1 is the flue gas of a power plant boiler, and the steam 16 is waste steam generated by hydrophobicity, exhaust steam from a deaerator, and the like.

[0048] The described Kalina cycle refers to the condensation of the ammonia liquid mixture 3 through the ammonia liquid circulation pump 4, the condenser 5-2 of the cooling evaporator 5, and the ammonia vapor produced through the ammonia vapor pipeline 19 and the phase change heat exchanger 6 Device 6-2 forms ammonia superheated steam 7, which is sent to ammonia steam turbine 8 to drive generator 10 to generate electricity, and the lean liquid produced by cooling evaporator 5 returns to ammonia condenser 9 through return line 13, and the exhausted steam at the outlet of ammonia steam turbine 8 After being cooled by the ammonia condenser 9, the ammonia liquid mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com