Self-adsorption air type foam dust suspension system for coal mining working face

A coal mining face, foam technology, applied in the direction of earth drilling, dispersed particle separation, cutting machinery, etc., can solve the problems that hinder the application of foam dust reduction technology, occupy a large space, low reliability, etc., and achieve wide practicability , small space occupation, and the effect of improving dust suppression efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

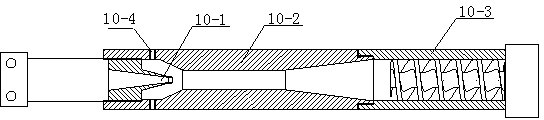

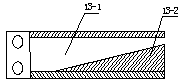

[0014] Such as figure 1 As shown, the self-suction air-type foam dust suppression system of the coal mining face of the present invention is mainly composed of a high-pressure water pipe 1, a control valve 2, a pressure regulating valve 3, a pressure gauge 4, a foaming agent adding device 5, a liquid storage tank 6, a main The liquid supply pipe 7, the branch liquid supply pipe 8, the regulating valve 9, the self-priming air swirl foaming device 10 arc-shaped foam nozzles; ~15MPa high-pressure rubber hose with a diameter of 25mm; the two branch liquid supply pipes 8 are high-pressure rubber hoses with a pressure bearing capacity of 8-10MPa, and their diameters are both 13mm; the main liquid supply pipe 7 at the end Two branch liquid supply pipes 8 leading to the left and right drums of the coal shearer are connected through the tee, and the entrances of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bearing capacity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com