Battery thermal management system based on heat pipe and liquid cooling device

A battery thermal management and cooling device technology, applied in secondary batteries, circuits, electrical components, etc., can solve the problem of high coolant temperature in the coolant outlet section, low coolant temperature in the coolant inlet section, and increased leakage points of the liquid cold plate. and other problems, to achieve uniform heat dissipation, improve heat exchange efficiency, and reduce flow power consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

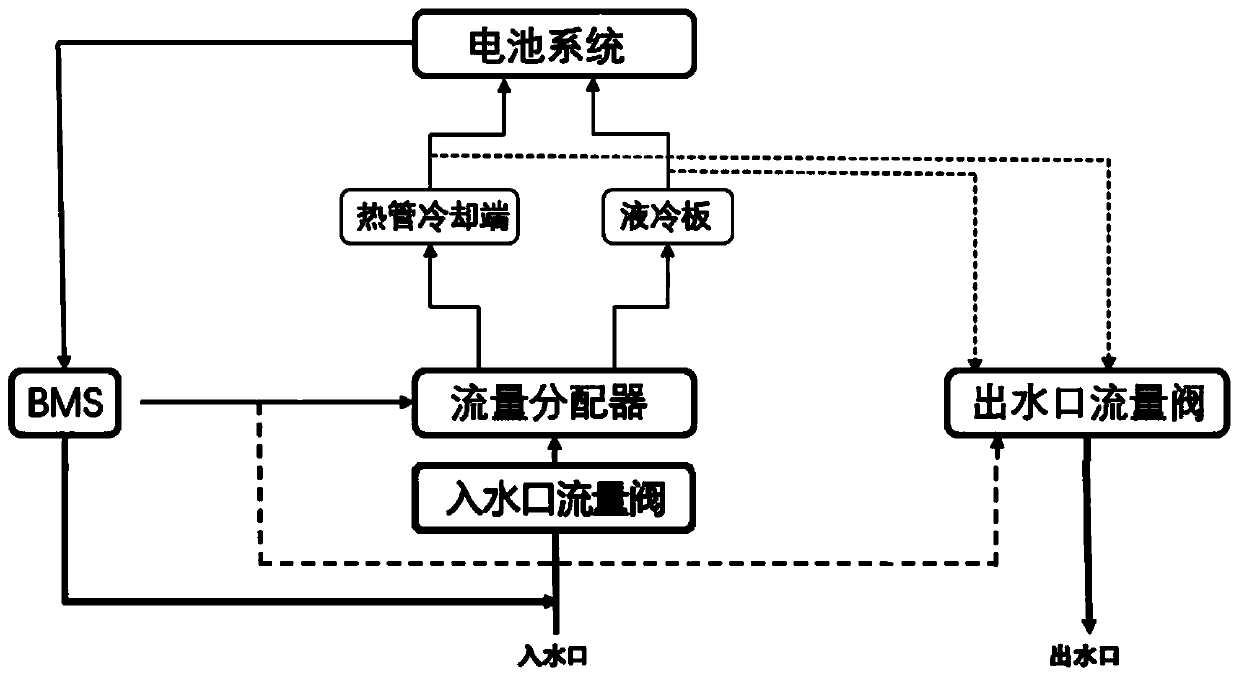

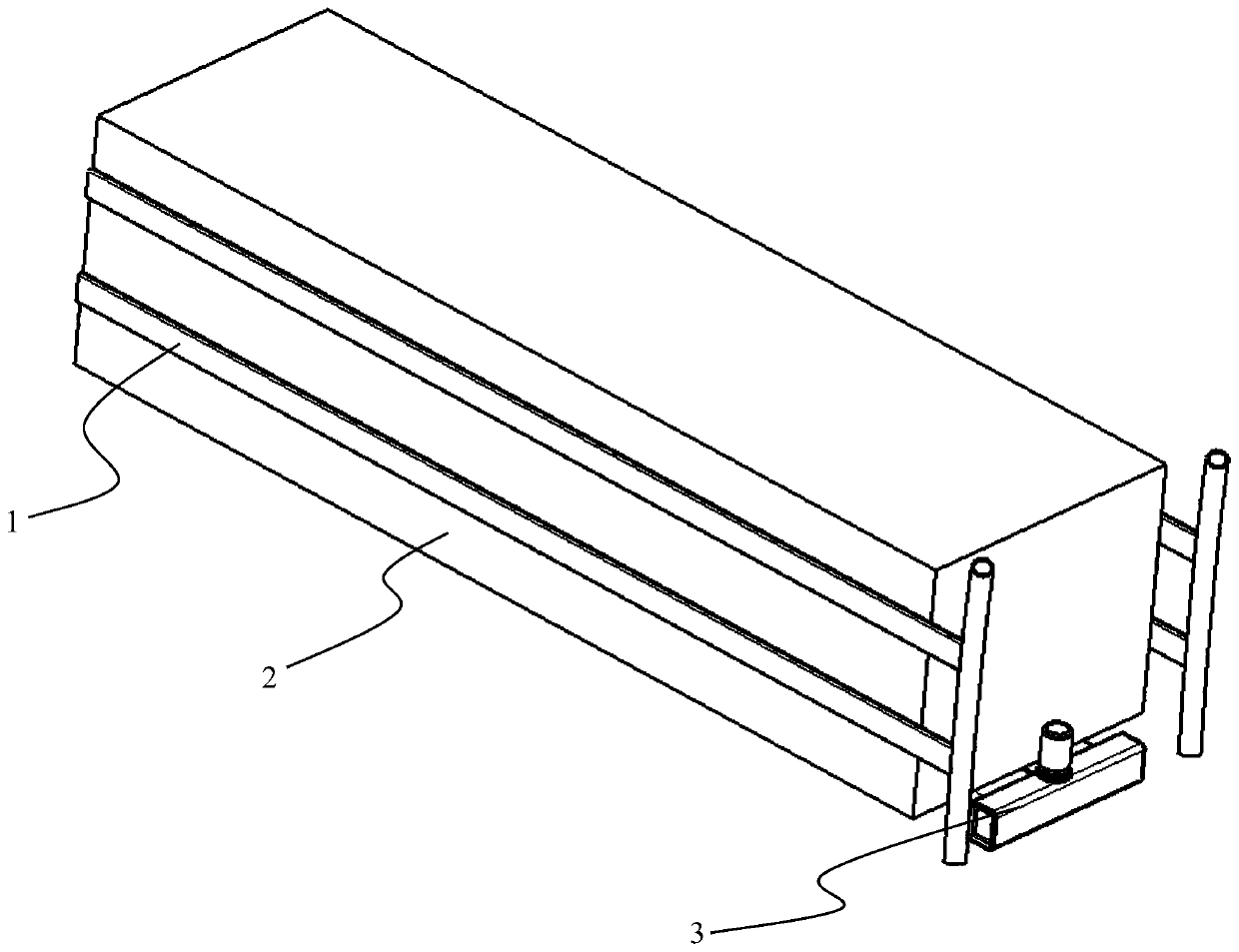

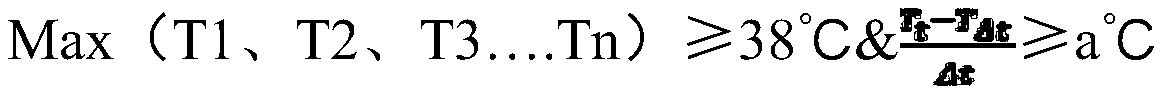

[0030] In this embodiment, the technical problem to be solved by the present invention is that the prior art uses a liquid-cooled plate, but when the liquid-cooled plate is installed on the side of the battery module, it needs to be fixed on the side, and the temperature of the coolant at the inlet section of the coolant is low, and the heat exchange effect Well, the coolant temperature at the coolant outlet section is high, the heat transfer effect is poor, and there is a temperature difference between the inlet and outlet water ends, and the use of a liquid cold plate will additionally increase the risk of leakage. A battery thermal management system based on heat pipes and liquid cooling devices is provided. A battery thermal management system based on heat pipes and liquid cooling devices includes:

[0031] A battery module 2, a cooling device and a control device, the control device and the cooling device communicate with each other through electrical signals, the cooling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com