Micro-displacement optical test method and device thereof

An optical test and micro-displacement technology, which is applied in the direction of using optical devices, measuring devices, and using optical devices to transmit sensing components, can solve problems such as expensive, complex and large equipment, and achieve error elimination, weight and size reduction, Simple structure and easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A micro-displacement optical test method:

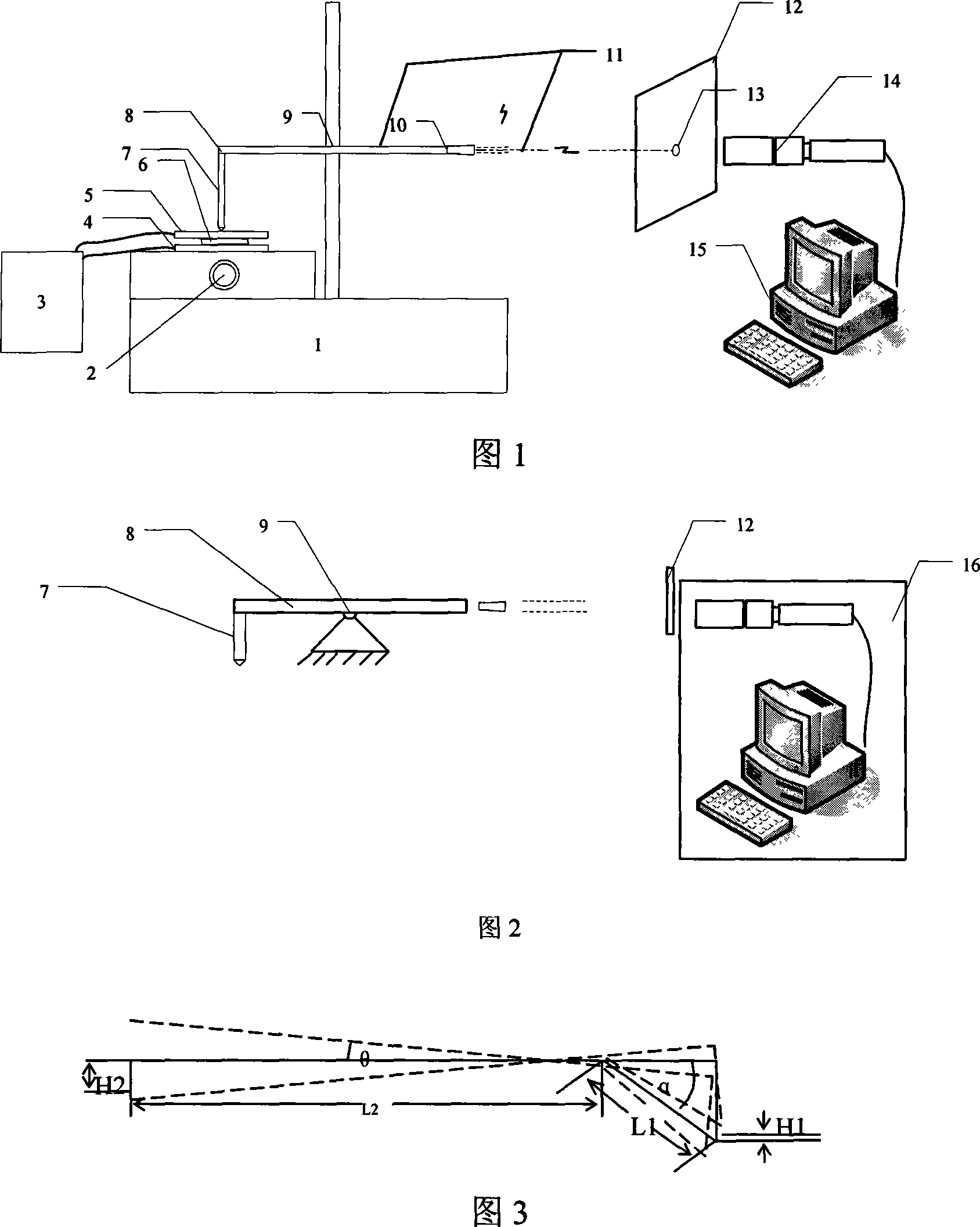

[0032] Step 1: Take the lever, support the lever 9 and make the lever form the short arm 8 and the long arm 11, and set the laser 10 on the long arm 11; take the projection surface 12, place the projection surface 12 in front of the laser 10, and make the The light spot emitted by the laser 10 is projected onto the projection surface 12,

[0033] Step 2 Take a point on the short arm 8 of the lever as the input end of the micro-displacement, input the micro-displacement to be measured from the input end of the micro-displacement, after being enlarged by the lever, an enlarged light spot displacement is generated on the projection surface 12, and then use the light spot displacement The measuring device 16 measures the displacement value of the light spot, and obtains the micro-displacement to be measured through calculation.

[0034] The laser 10 is placed at the end of the long arm 11 so that the laser beam generated by the l...

Embodiment 2

[0036] As shown in Figure 1, a kind of device that realizes above-mentioned micro-displacement optical test method, comprises: light spot displacement measuring device 16, also comprises lever, and this lever is arranged on support 9, uses a point on the short arm 8 of lever as to-be-measured The input end of the micro-displacement is provided with a laser 10 on the long arm 11 of the lever, and a projection surface 12 for displaying the displacement of the light spot is provided in front of the laser 10. The above-mentioned light spot displacement measurement device 16 is used for the displacement of the light spot emitted by the laser 10. Acquisition and calculation of micro-displacement.

[0037] The laser 10 is arranged at the end of the long arm 11 of the lever, and the laser beam generated by the laser 10 is parallel to the lever.

[0038]The end of the lever short arm 8 is used as the input end of the micro-displacement to be measured.

[0039] The present invention al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com