Preparation method of copper-loaded nanoscale conductive polystyrene

A technology of polystyrene and sulfonated polystyrene, which is applied in the nanometer field, can solve the problems of inconsistent conductivity of conductive materials, high cost and large-scale application, and high price of carbon black, etc., and achieves light polymer weight, environmental friendliness and designability strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

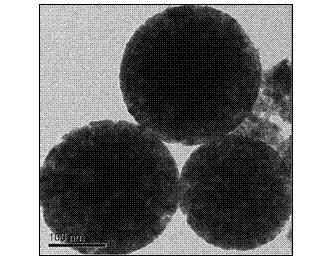

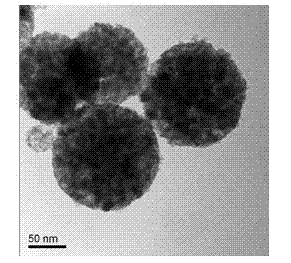

Image

Examples

Embodiment 1

[0037] (1) Preparation of polystyrene:

[0038] Put 15.0g of styrene, 3.0g of PVP, 0.2g of azobisisobutyronitrile, and 250mL of ethanol solution with a mass concentration of 90% into a container with a stirring device and a condensing device, and blow nitrogen at room temperature After 2 hours, drive out the oxygen dissolved in water, heat to 80°C, stir and react for 25 hours, wash the generated product with ethanol, and dry for 10 hours to obtain polystyrene;

[0039] (2) Preparation of sulfonated polystyrene microsphere sol:

[0040] Take 3g of polystyrene powder prepared in (1), add it to 30ml of concentrated sulfuric acid with a mass concentration of 99%, stir and heat to 40°C, react for 3 hours, and wash the sulfonated polystyrene with ethanol 5 times after centrifugal filtration. Put into ultrapure water again and be sol-like, obtain the sulfonated polystyrene microsphere sol that mass concentration is 5%;

[0041] (3) Preparation of nanoscale conductive polystyrene lo...

Embodiment 2

[0046] (1) Preparation of polystyrene:

[0047] Add 9.0g of styrene, 0.9g of PVP, 0.1g of azobisisobutyronitrile, and 100mL of ethanol solution with a mass concentration of 98% into a container with a stirring device and a condensing device, and pass it through at room temperature Nitrogen for 3 hours, after driving out the oxygen dissolved in water, heat to 50°C, stir and react for 30 hours, wash the generated product with ethanol, and dry for 15 hours to obtain polystyrene;

[0048] (2) Preparation of sulfonated polystyrene microsphere sol:

[0049] Take 3g of polystyrene powder prepared in (1), add it to 30ml of concentrated sulfuric acid with a mass concentration of 95%, stir and heat to 30°C, and react for 5 hours. The sulfonated polystyrene is washed twice with ethanol after centrifugal filtration. Put into distilled water again and be sol-like, obtain the sulfonated polystyrene microsphere sol that mass concentration is 8%;

[0050] (3) Preparation of nanoscale conduc...

Embodiment 3

[0055] (1) Preparation of polystyrene:

[0056] Add 22.0g of styrene, 2.3g of PVP, 0.47g of azobisisobutyronitrile, and 200mL of ethanol solution with a mass concentration of 95% into a container with a stirring device and a condensing device, and blow nitrogen gas at room temperature After 10 hours, drive out the oxygen dissolved in water, heat to 80°C, stir and react for 15 hours, wash the resulting product with ethanol, and dry it for 16 hours to obtain polystyrene;

[0057] (2) Preparation of sulfonated polystyrene microsphere sol:

[0058] Take 3g of polystyrene powder prepared in (1), add it to 30ml of concentrated sulfuric acid with a mass concentration of 90%, stir and heat to 50°C, react for 2 hours, and wash the sulfonated polystyrene with ethanol 6 times after centrifugal filtration. Put into deionized water again and be sol-like, obtain the sulfonated polystyrene microsphere sol that mass concentration is 7%;

[0059] (3) Preparation of nanoscale conductive polys...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com