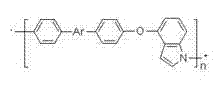

Preparation method of soluble heat-resistant polymer based on benzpyrole skeleton

A polymer and soluble technology, which is applied in the field of preparation of new soluble heat-resistant polymers, can solve the problems of poor solubility, single processing method, and low glass transition temperature, and achieve mild reaction conditions and low reaction temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

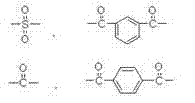

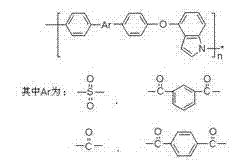

Embodiment 1

[0021] Choose a 100 mL three-necked flask as the reaction vessel, vacuum and fill the three-necked flask with nitrogen, repeat three times. Add 2.66g 4-hydroxyindole, 4.36g 4,4-difluorobenzophenone and 5.52g anhydrous potassium carbonate in a three-necked flask, then add 20mL solvent N-methylpyrrolidone, and use mechanical stirring to make the reaction The monomer is fully dissolved in the solvent. The system was slowly heated to 160°C and reacted for 1 hour; the temperature was increased to 190°C and the reaction continued for 3 hours. The viscosity of the system increased significantly and the reaction was stopped. The reaction system was slowly cooled to room temperature, and then poured into deionized water for precipitation to obtain a crude product of indole skeleton polymer. The crude polymer product was extracted with methanol for 24 hours, and then dried in a vacuum drying oven at 100°C for 8 hours to obtain the target polymer I.

[0022]

[0023] This is an amorphous...

Embodiment 2

[0025] Choose a 100 mL three-necked flask as the reaction vessel, vacuum and fill the three-necked flask with nitrogen, repeat three times. In a three-necked flask were sequentially added 2.66g 4-hydroxyindole, 5.08g 4,4-difluorodiphenyl sulfone and 5.52g anhydrous potassium carbonate, and then added 20mL solvent N-methylpyrrolidone, using mechanical stirring to make the reaction The body is fully dissolved in the solvent. The system was slowly heated to 160°C and reacted for 1 h; then the temperature was increased to 180, and the reaction continued for 2 h. The viscosity of the system increased significantly and the reaction was stopped. The reaction system was slowly cooled to room temperature, and then poured into deionized water for precipitation to obtain a crude product of indole skeleton polymer. The crude polymer product was extracted with methanol for 24 hours, and then dried in a vacuum drying oven at 100°C for 8 hours to obtain the target polymer II.

[0026]

[0027...

Embodiment 3

[0029] Choose a 100 mL three-necked flask as the reaction vessel, vacuum and fill the three-necked flask with nitrogen, repeat three times. In a three-necked flask were sequentially added 2.66g 4-hydroxyindole, 6.44g 1,3-bis-(4-fluorobenzoyl)benzene and 5.52g anhydrous potassium carbonate, and then added 20mL of solvent N-methylpyrrolidone, using The mechanical stirring makes the reaction monomer fully dissolved in the solvent. The system was slowly heated to 160°C and reacted for 1 h; then the temperature was increased to 180, and the reaction continued for 2 h. The viscosity of the system increased significantly and the reaction was stopped. The reaction system was slowly cooled to room temperature, and then poured into deionized water for precipitation to obtain a crude product of indole skeleton polymer. The crude polymer product was extracted with methanol for 24 hours, and then dried in a vacuum drying oven at 100°C for 8 hours to obtain the target polymer III.

[0030] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com