Waterborne polyurethane elastic dispersion and preparation method thereof

A water-based polyurethane, elastic polyurethane technology, used in polyurea/polyurethane coatings, coatings, textiles and papermaking, etc., can solve the problem of high price of hydroxyl-terminated polydialkylsiloxane, limited filler dosage, and lack of high extinction or matte etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0114] A method for preparing an aqueous polyurethane elastic dispersion includes the following steps:

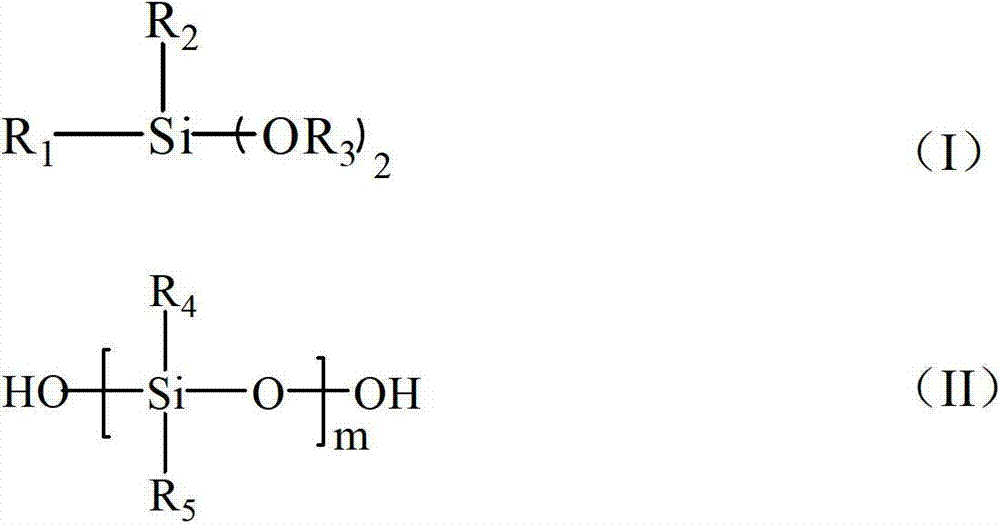

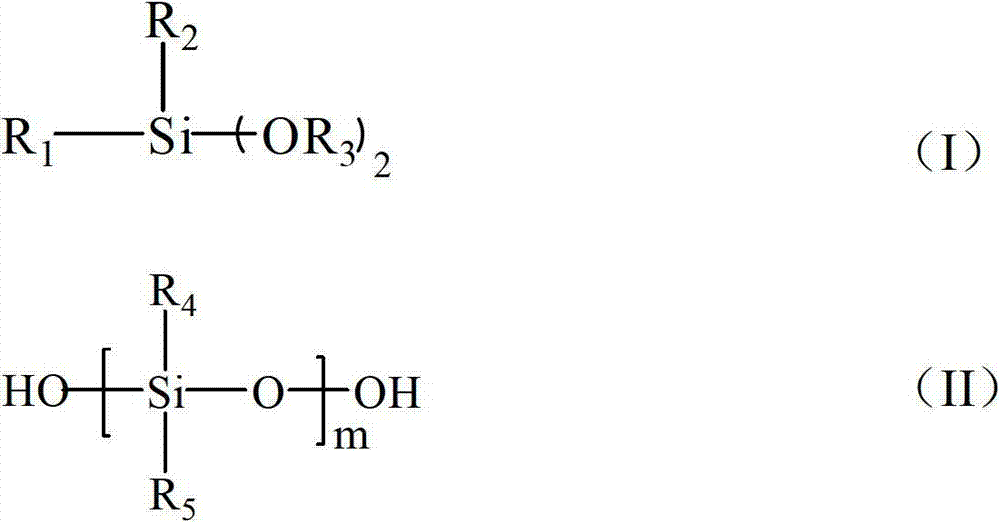

[0115] (1) Add the compound represented by the general formula (I) and / or the hydrophilic crosslinking agent into the three-necked flask, pass in moist air while stirring, stir under the elevated temperature, add the compound represented by the general formula (II), and stir After homogenization, heat and reduce pressure to distill to remove small molecular alcohol to obtain siloxane polymer;

[0116] (2) Then add macromolecular polyol and isocyanate to the siloxane polymer (residue of vacuum distillation) obtained in step (1), and then continue the reaction after heating the mixture to cause chain extension polymerization;

[0117] Or adding a polyurethane prepolymer obtained from macromolecular polyols and isocyanates to the siloxane polymer (residue of vacuum distillation) obtained in step (1);

[0118] Then cool the mixture, add small molecule chain extenders and / or hydrophilic...

Embodiment 1

[0121] A method for preparing an aqueous polyurethane elastic dispersion includes the following steps:

[0122] (1) Add 1 kg of the compound of general formula (I) into a three-necked flask, add air with a humidity of 40% under stirring, and after stirring at 60°C for 3 hours, add 5 kg of the compound of general formula (2), stir well and heat and reduce pressure Distillation to remove small molecular alcohol to obtain siloxane polymer; wherein, R in general formula (I) 1 Dodecyl, R 2 Tetradecyl, R 3 Is ethyl; R in general formula (II) 4 , R 5 Methyl, m=4;

[0123] (2) Add 100kg of polyester diol SP-2060 (Shanghai Shanji Chemical) and 113kg of polyisocyanate IPDI (Pasto Company) to the siloxane polymer obtained in step (1), and react 0.5 at 90°C. h Carry out chain extension polymerization; then cool to 60°C, add 3 kg of hydrophilic cross-linking agent DMPA (Pasto Company) and small molecule chain extender 1,4-butanediol (Beijing Yili Chemical Company, CP) 0.1 kg, react for 2h to c...

Embodiment 2

[0125] A method for preparing an aqueous polyurethane elastic dispersion includes the following steps:

[0126] (1) Add 6kg of compound of general formula (I) and 12kg of compound of general formula (2) into a three-necked flask, and mix with 60% air humidity under stirring. Stir at 50℃ for 2 hours, stir well and heat under reduced pressure for distillation Removal of small molecular alcohols to obtain siloxane polymers; wherein, R in general formula (I) 1 Cetyl, R 2 Dodecyl, R 3 Is ethyl; R in general formula (II) 4 , R 5 Is a methyl group, m=4;

[0127] (2) Add 100kg of polyester carbonate diol PCD964 (Shanghai Shanji Chemical) and 23kg of polyisocyanate MDI (Pasto Company) to the siloxane polymer obtained in step (1), and react for 3h at 70°C Carry out chain extension polymerization; then cool to 55°C, add 8kg of hydrophilic cross-linking agent sodium ethylenediaminoethanesulfonate A95 (Degussa) and small molecule chain extender 1,6-hexanediol (Beijing Yili Chemical Company, CP...

PUM

| Property | Measurement | Unit |

|---|---|---|

| gloss | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com