Anhydrous sodium sulfate preparation method and anhydrous sodium sulfate preparation apparatus

A technology of Yuanming powder and clarification device, applied in chemical instruments and methods, alkali metal sulfites/sulfites, alkali metal compounds, etc., can solve the problem that the skin transportation process covers a large area and is easily polluted by fine nitrate dust. environment, prone to vacuum leakage and other problems, to achieve the effect of reducing investment costs and maintenance costs, less environmental pollution, and avoiding easy sand leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The following non-limiting examples illustrate the invention.

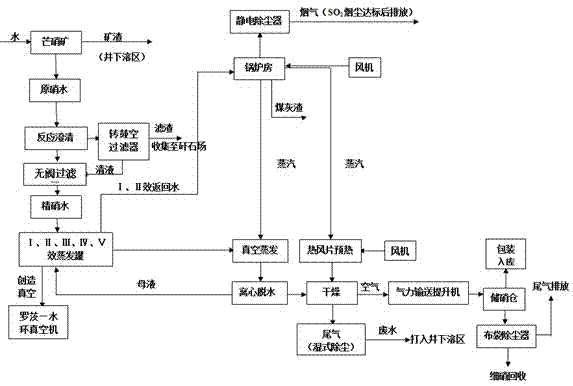

[0042] Such as Figures 1 to 4 Shown, a kind of Yuanming powder preparation method comprises the following steps successively:

[0043] 1) Raw nitrate to refine nitrate, such as figure 2 Shown: The raw nitric water produced by Glauber’s salt mine is clarified by reaction (the nitric water is preheated by the nitric water preheating device, then enters the nitric water reaction clarification device, and alkali is added to the nitric water reaction clarification device to remove Ca 2+ , Mg 2+ impurities), the clear liquid is passed through a valveless filter to obtain refined nitric water, the turbid liquid is passed through a drum vacuum filter to obtain clear liquid, and then passed through a valveless filter to obtain refined nitric water, specifically:

[0044] A) The supernatant after the clarified nitric water reaction is filtered through a valveless filter to obtain fine nitric water;

[0045] B) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com