Layered composite material for sliding elements, method for producing same and use thereof

A technology for composite materials and sliding elements, which is applied to the layered composite materials used for sliding elements. It is used for the production of the composite materials and its application fields. It can solve the problems of insufficient strength of the sliding layer and achieve high hardness and high durability. Corrosion, effect of improving sliding ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In the sense of the present invention, a sliding element means: an element having a sliding surface in sliding contact with a mating end face. Sliding elements according to the invention are preferably sliding bearings, bushings, cylinders, pistons, pins, seals, valves and pressure cylinders. Particularly preferably the sliding element according to the invention is a sliding bearing, in particular for an internal combustion engine, eg a crankshaft bearing, a camshaft bearing or a connecting rod bearing.

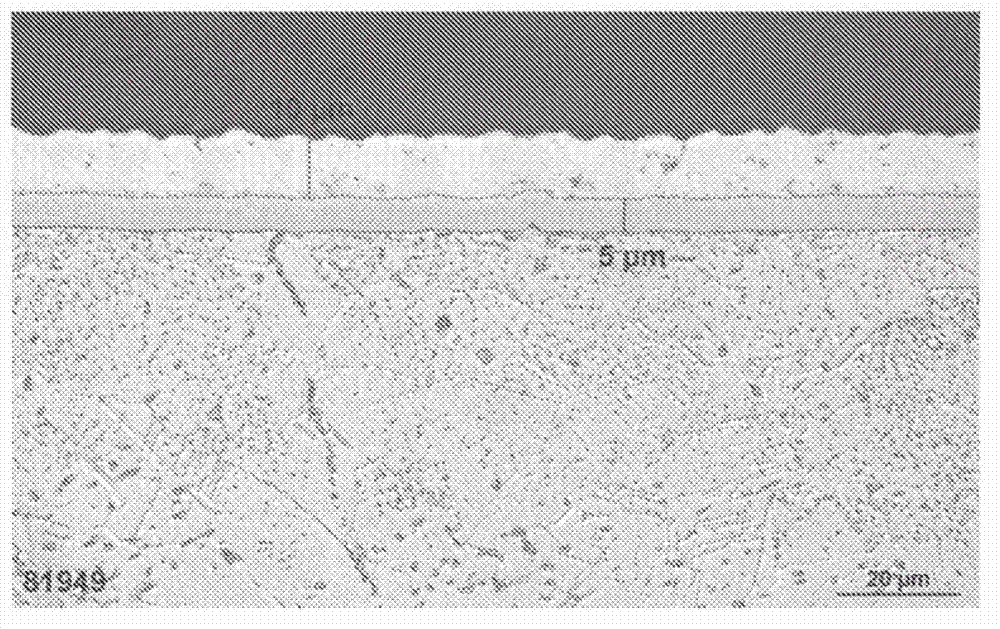

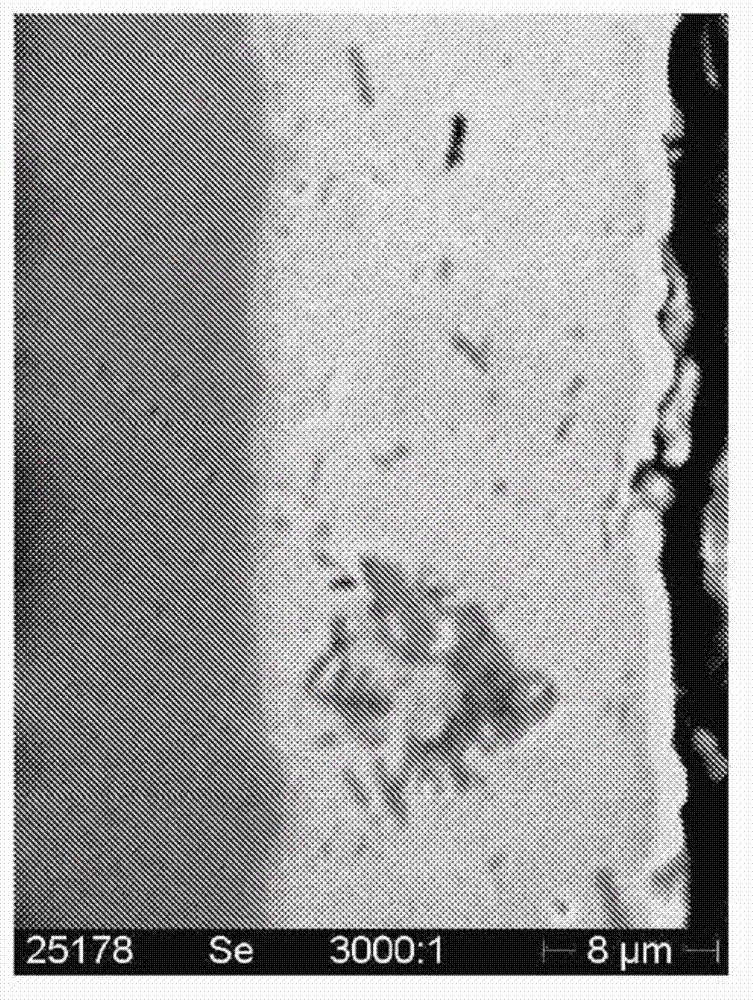

[0017] Plain bearings generally have the following layer structure: a support made of steel (material of the plain bearing), a base or bearing metal layer (the so-called substrate), optionally a dam or diffusion barrier layer and a metal or metal alloy made sliding layer. The bearing metal layer can be, for example, a copper alloy layer, in particular a sintered or cast copper alloy layer. The sliding layer can, for example, be galvanized.

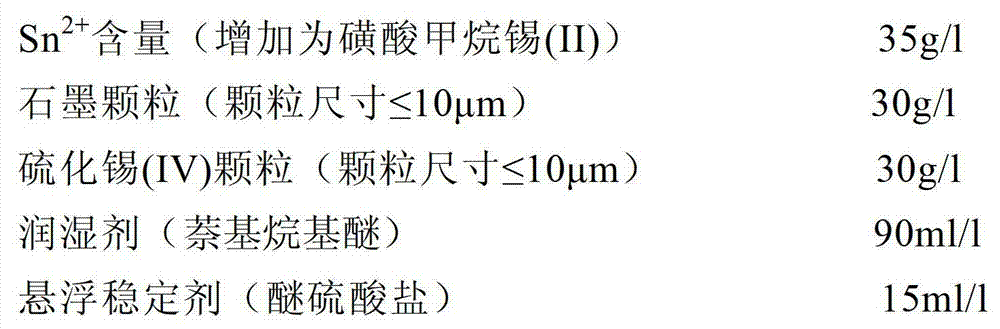

[0018] Due to the extrem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mohs hardness | aaaaa | aaaaa |

| Mohs hardness | aaaaa | aaaaa |

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com