Method for preparing lithium manganate anode materials of lithium ion battery

A battery lithium manganate and cathode material technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of uneven distribution of manganese and lithium, structural defects, inability to mix raw materials evenly, etc., to improve the cycle life and production process. Simple, low production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A preparation method of a lithium ion battery lithium manganate cathode material of the present invention, comprising the following steps:

[0020] (1) Pretreatment: Add lithium carbonate and manganese dioxide into a stirring mixer, mix and stir for 4 hours, where Li:Mn = 0.58:1 (molar ratio), place the resulting mixture in a rotary kiln, and keep warm at 650°C Run for 2 hours, then cool down naturally.

[0021] (2) Calcination: Put the pretreated product in a calcination furnace (in a tunnel kiln) to raise the temperature to 850°C, calcinate in air atmosphere for 15 hours, then cool down to below 600°C at a rate of 3°C / min, and then cool naturally to room temperature.

[0022] (3) The reaction product obtained in step (2) is crushed, and then sieved through 400 mesh to obtain lithium manganate cathode material (ie, lithium manganate powder) for lithium ion batteries.

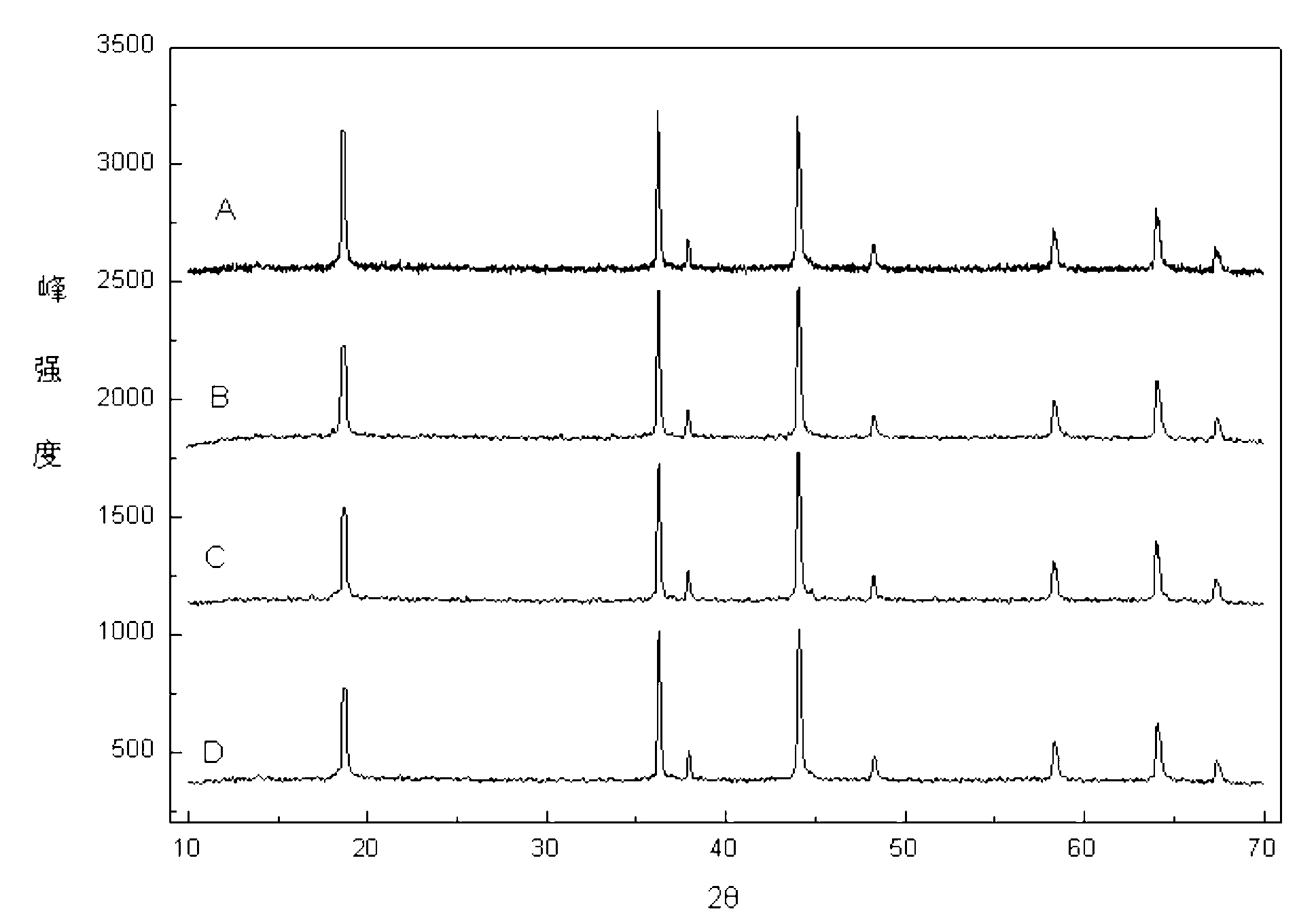

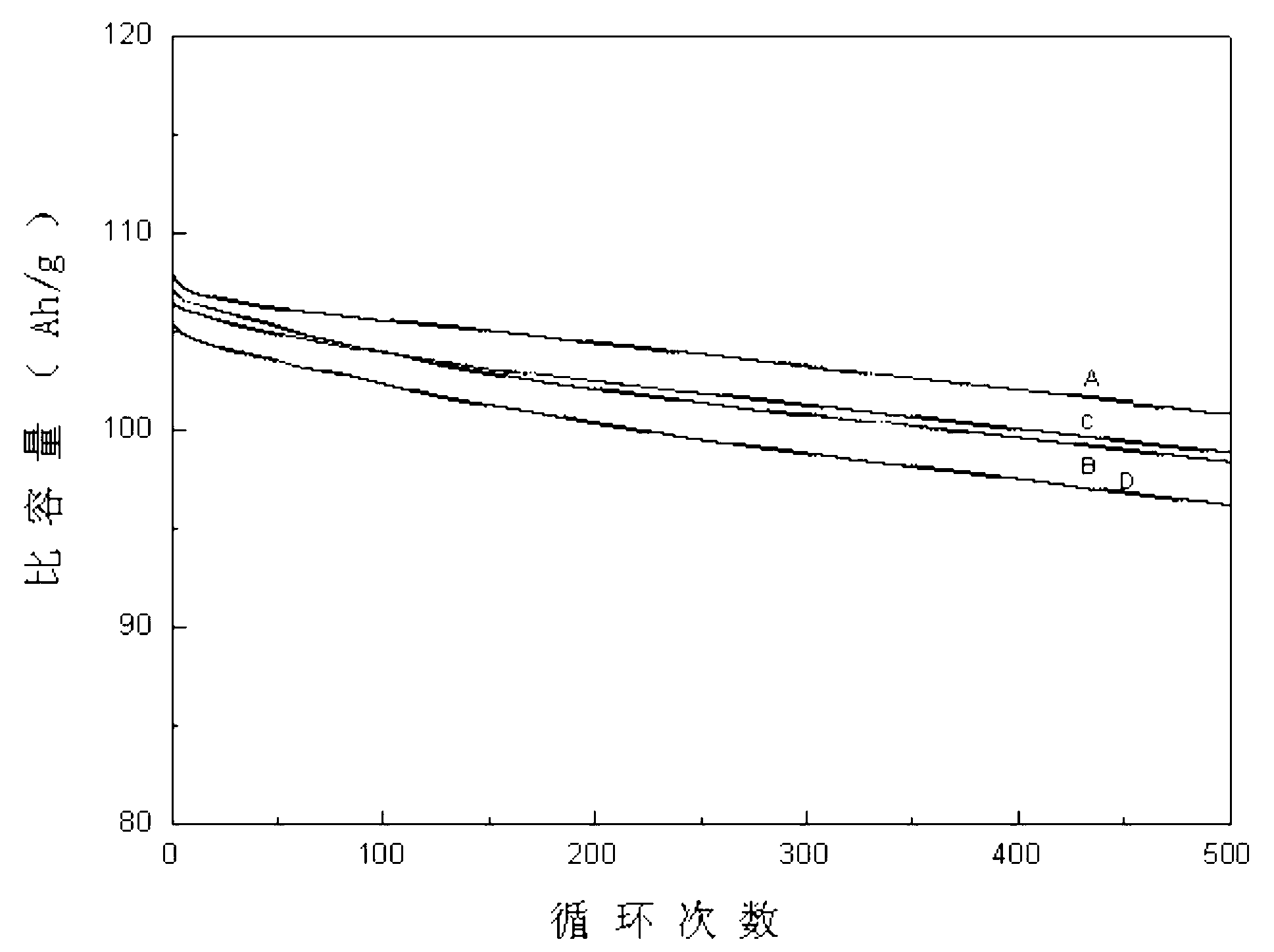

[0023] Such as figure 1 As shown, curve A is the XRD pattern of the lithium manganate powder prepa...

Embodiment 2

[0027] A preparation method of a lithium ion battery lithium manganate cathode material of the present invention, comprising the following steps:

[0028] (1) Pretreatment: Add lithium hydroxide and spherical trimanganese tetroxide into a stirring mixer and stir for 4 hours, where Li:Mn = 0.58:1 (molar ratio), and place the resulting mixture in a rotary kiln at 500 Keep warm at ℃ for 2 hours, then cool down naturally.

[0029] (2) Calcination: heat the pretreated product to 800°C in a calcination furnace, calcine in an air atmosphere for 15 hours, then cool down to below 600°C at a rate of 3°C / min, and then cool naturally to room temperature.

[0030] (3) The reaction product obtained in step (2) is crushed, and then sieved through 400 mesh to obtain lithium manganate cathode material (ie, lithium manganate powder) for lithium ion batteries.

[0031] Such as figure 1 As shown, curve B is the XRD pattern of the lithium manganate powder prepared in this example. It can be seen...

Embodiment 3

[0034] A preparation method of a lithium ion battery lithium manganate cathode material of the present invention, comprising the following steps:

[0035] (1) Pretreatment: Add lithium carbonate and trimanganese tetraoxide into a stirring mixer and stir for 4 hours, where Li:Mn = 0.58:1 (molar ratio), and place the resulting mixture in a rotary kiln at 650°C Keep warm for 2 hours, then cool down naturally.

[0036](2) Calcination: heat up the pretreated product to 800°C in a calcination furnace, calcinate in an air atmosphere for 15 hours, then cool down to below 600°C at a rate of 3°C / min, and then cool naturally to room temperature.

[0037] (3) The reaction product obtained in step (2) is crushed, and then sieved through 400 mesh to obtain lithium manganate cathode material (ie, lithium manganate powder) for lithium ion batteries.

[0038] Such as figure 1 As shown, curve C is the XRD pattern of the lithium manganate powder prepared in this example. It can be seen from th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com