Lithium ion power battery composite cathode material and its preparation method

A negative electrode material and power battery technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of reducing the first irreversible capacity of natural microcrystalline graphite, affecting the first charge and discharge performance of the material, and unfavorable battery manufacturing process, so as to avoid irreversibility. loss, good charge-discharge cycle performance, and uniform surface properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

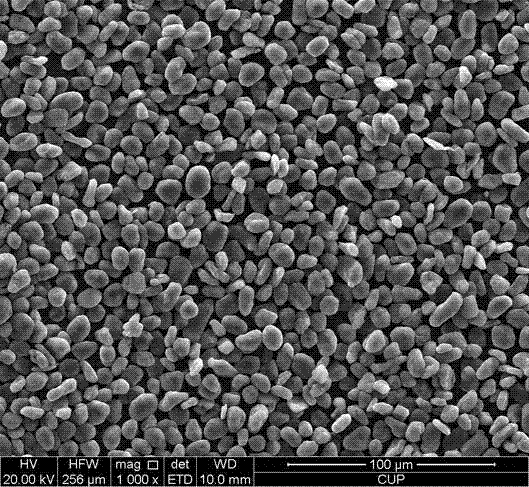

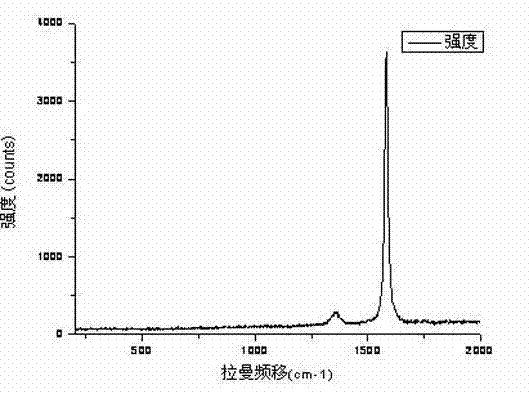

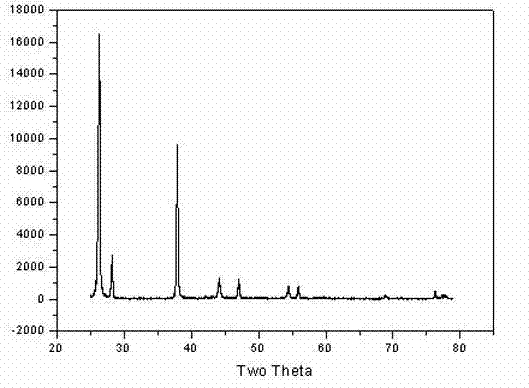

[0035] A lithium ion power battery composite negative electrode material is prepared by the following method:

[0036] Take 24 g of thermosetting resin phenolic resin and 240 g of solvent anhydrous ethanol and mix them evenly at room temperature, add 300 g of natural graphite with an average particle size of 4.0? The resin is mixed evenly, and then the curing agent H is added. 3 PO 4 And continue to stir until the mixture is uniform, then heat the solution to remove the organic solvent contained in it, and then carry out curing treatment to obtain a thermosetting resin mixture after curing treatment. , and then cured at 60°C for 2h; add 15g of secondary modifier coal tar pitch to the cured sample, raise its temperature to 400°C at a heating rate of 0.1°C / min for 2h to obtain the secondary modification mixture; the mixture after the secondary modification is heated to 800°C at a heating rate of 5°C / min, reacted in an inert gas atmosphere for 2 hours and then naturally lowered...

Embodiment 2

[0038] Same as Example 1, the difference is that the thermosetting resin is epoxy resin and furan resin; and the modifier is petroleum asphalt.

Embodiment 3

[0040] A lithium ion power battery composite negative electrode material is prepared by the following method:

[0041] Take 24 g of thermosetting resin epoxy resin and 240 g of solvent anhydrous ethanol and mix them evenly at room temperature, add 300 g of natural graphite with an average particle size of 9.0 μm, and mechanically stir the above mixture in a stirring tank for 3 hours to make natural graphite and The thermosetting resin is mixed evenly, and then the curing agent H is added. 3 PO 4 And continue to stir until the mixture is evenly mixed, then heat the solution to remove the organic solvent contained in it, and then carry out curing treatment to obtain a thermosetting resin mixture after curing treatment. , and then cured at 150°C for 5h; add 15g of secondary modifier coal tar pitch to the cured sample, raise its temperature to 600°C at a heating rate of 3°C / min for 4h to obtain the secondary modification The mixture after the secondary modification is subjected ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Particle size distribution range | aaaaa | aaaaa |

| Layer spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com