Graphite coated aluminum radiator and manufacturing process thereof

A manufacturing process and radiator technology, applied in the cooling/heating device of lighting device, lighting and heating equipment, lighting device and other directions, can solve the problems of LED lighting lamps lifespan can not be greatly improved, low thermal conductivity, severe light decay, etc. Achieve the effect of light weight, good heat transfer effect and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

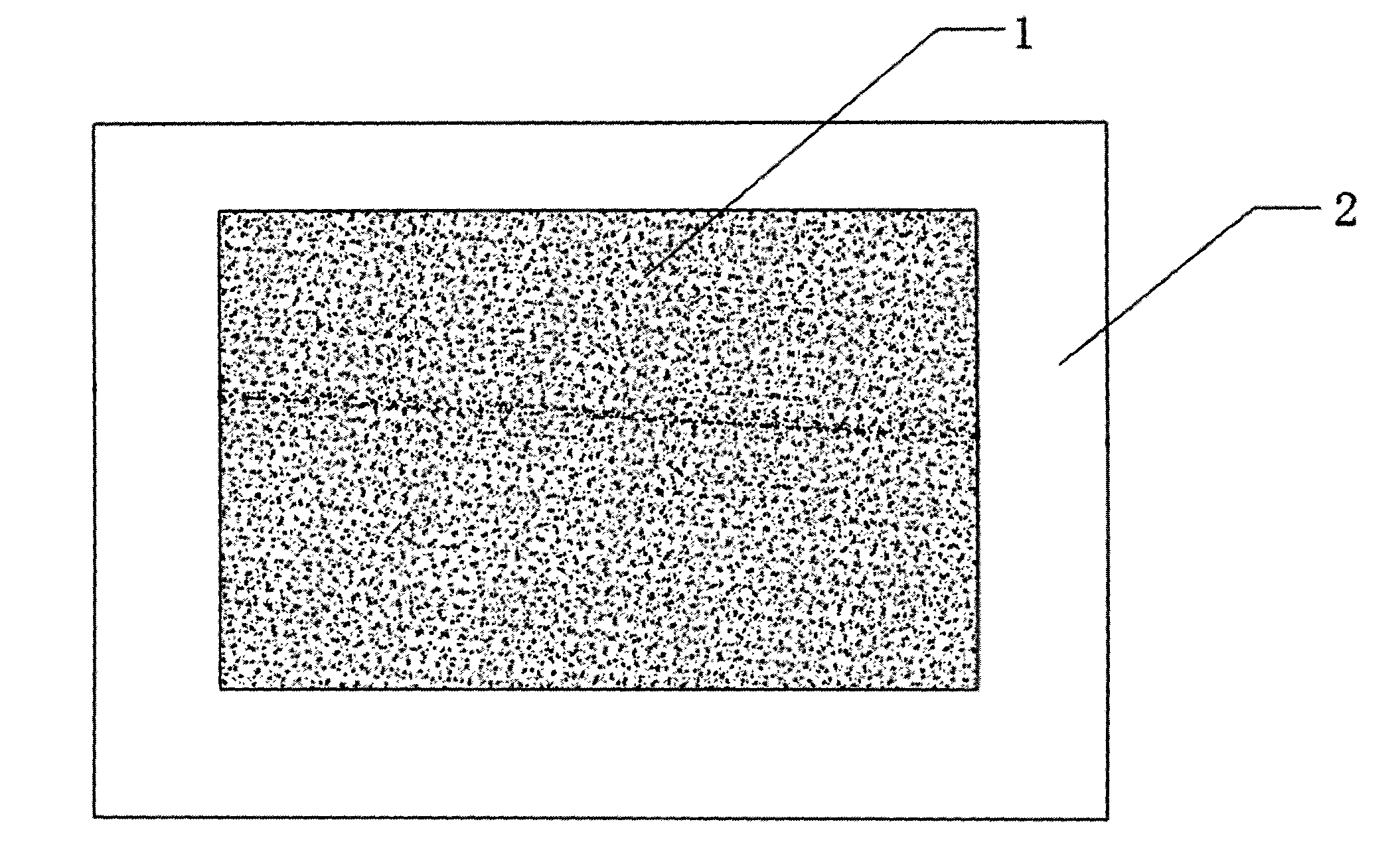

[0021] Such as figure 1 , figure 2 As shown, a graphite-coated aluminum radiator, the graphite-coated aluminum radiator is composed of WT70% graphite powder, WT5% copper powder, WT5% aluminum powder, WT14% silane coupling agent, WT6% titanate coupling agent is sintered at a high temperature of 1000°C-1200°C to obtain a graphite composition, and the graphite composition is made into a graphite block with high thermal conductivity through a molding production equipment, and the graphite block is cut into graphite of a specified size as required The graphite sheet is used as a heat-conducting base material and coated in an aluminum heat dissipation substrate, that is, a graphite-coated aluminum heat sink is made.

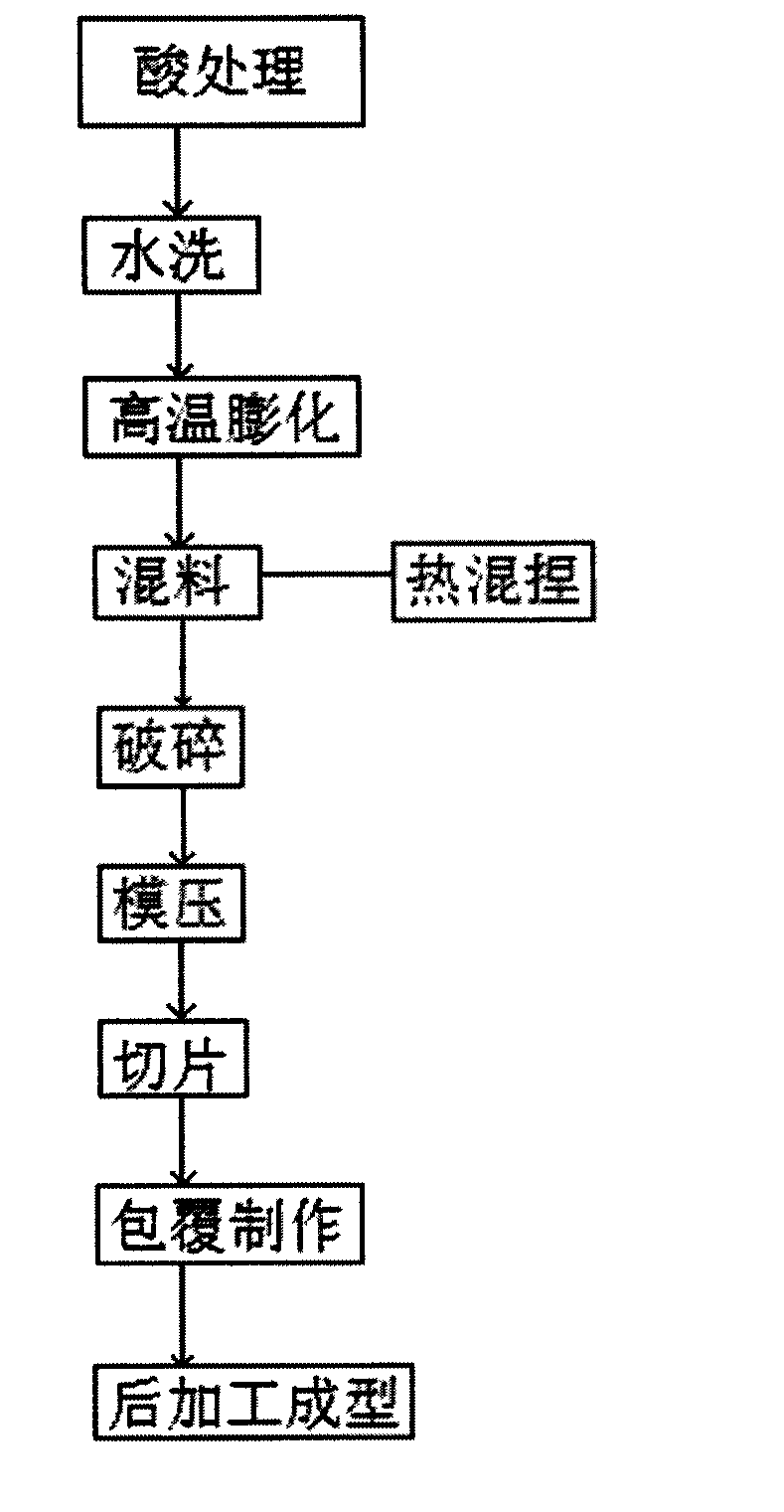

[0022] A kind of manufacturing process of the aluminum heat sink coated with graphite of the present invention, this process mainly comprises the following steps:

[0023] 1), acid treatment: put the finely ground graphite powder (particle diameter≤0.9mm) with a car...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com