Safety starter for air-cooled diesel engine

A diesel engine and starter technology, which is applied in the direction of engine starting, machine/engine, starting device with mechanical power storage, etc., can solve the problems of diesel engine personnel injury, achieve long service life, ingenious conception, and improve safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

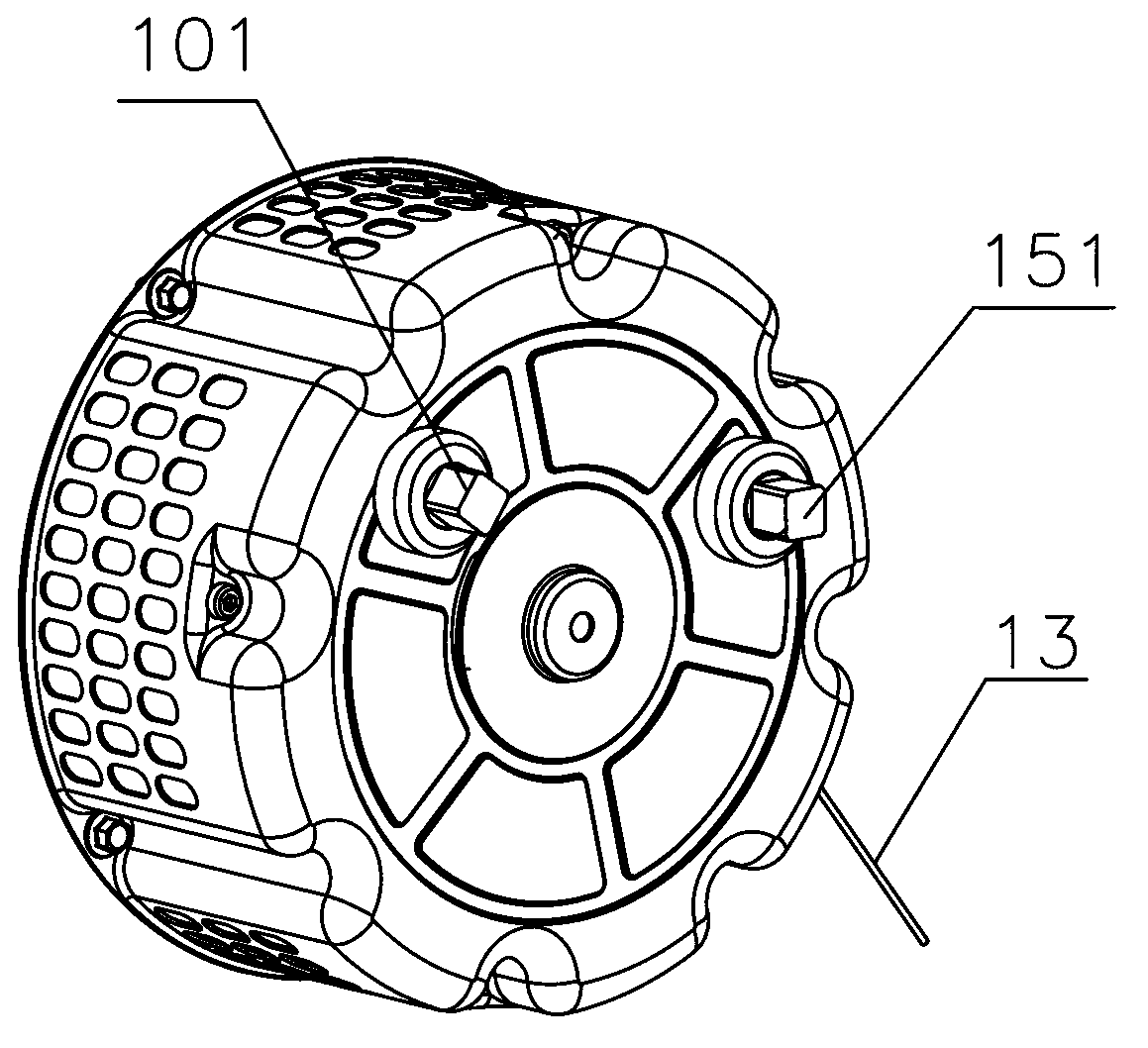

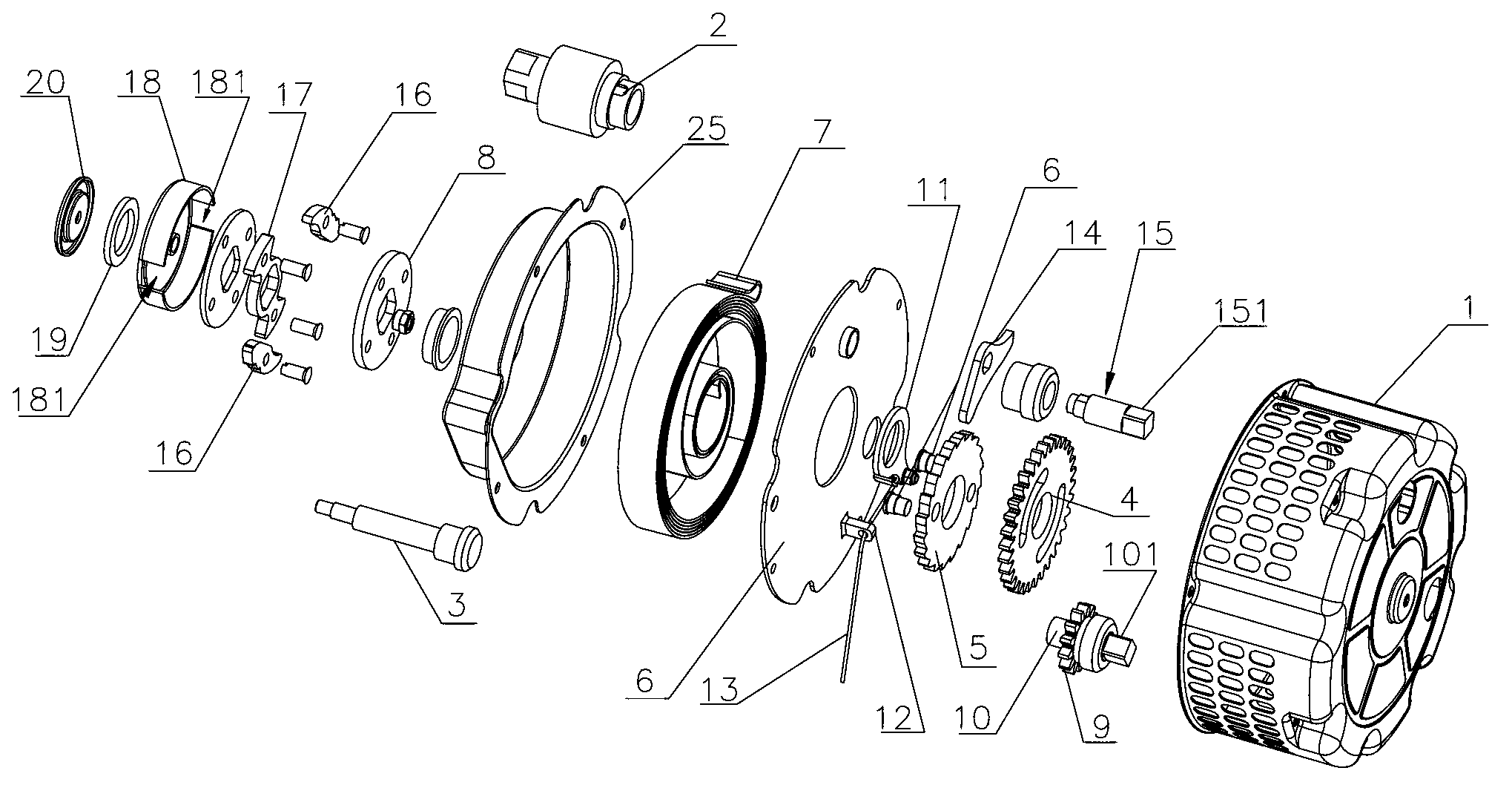

[0037] refer to figure 1 figure 2 image 3 Figure 4 , the present invention comprises a casing 1 and a rotating shaft 2 rotatably connected to the center of the bottom surface of the casing, the rotating shaft 2 is a hollow shaft, and a mandrel 3 is fixedly arranged inside it;

[0038] A driven gear 4, a ratchet 5, a scroll spring fixing plate 6, a scroll spring 7 and a starting pawl seat 8 are sequentially installed on the rotating shaft 2;

[0039] The scroll spring fixing plate 6 is fixedly connected with the inner wall of the casing 1;

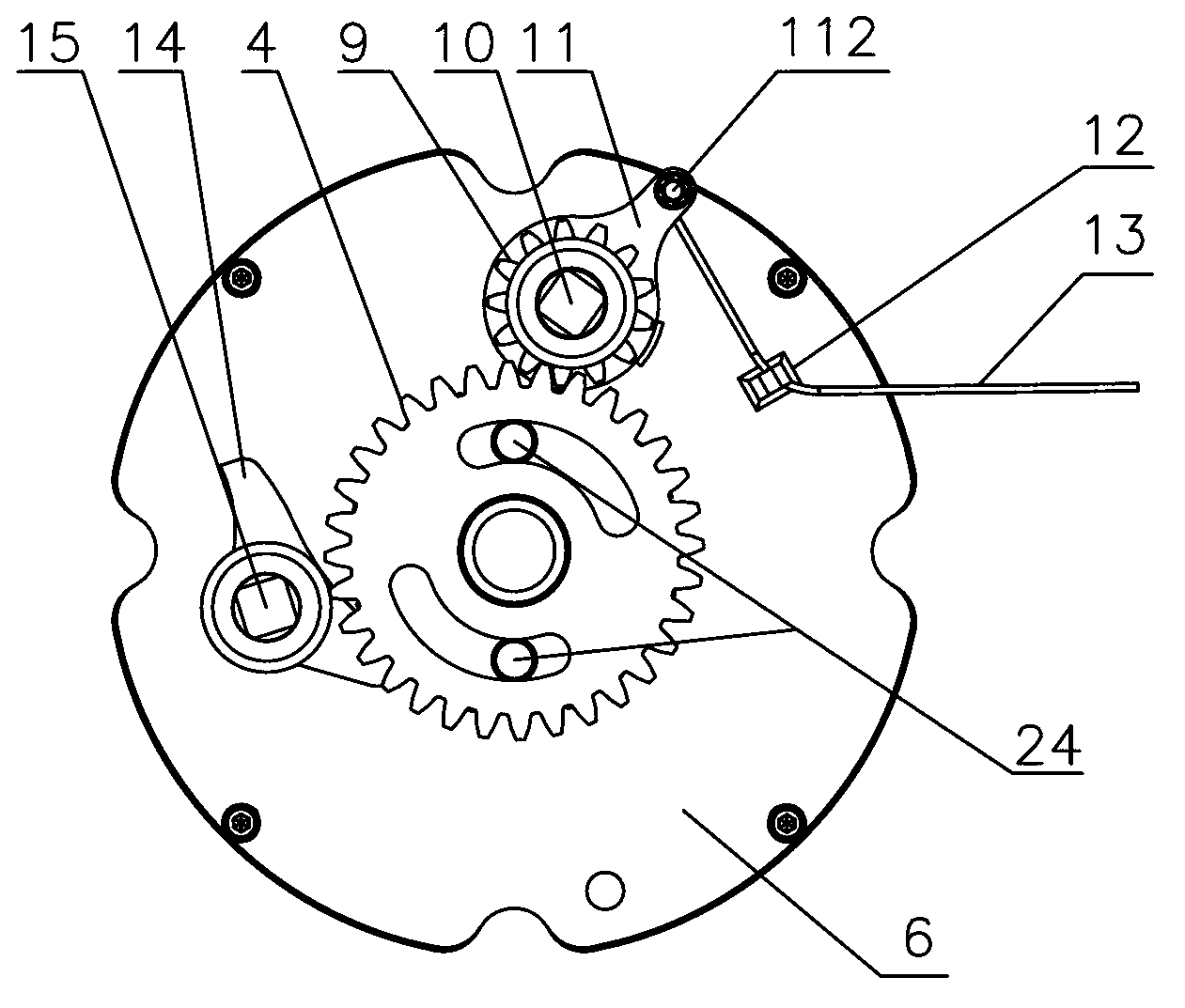

[0040]The driven gear 4 is meshed with a preload gear 9, and the center of the preload gear 9 is provided with a preload shaft 10. One end of the preload shaft 10 is supported on the scroll spring fixed plate 6, and the other end protrudes from the casing 1 as a preload end 101. , a block 11 is also set on the pretension shaft 10, such as Figure 9 As shown, the edge of the block 11 has a locking tooth 111 arranged perpendicular to ...

Embodiment 2

[0046] like Figure 5 Image 6 , embodiment 2 is a further improvement on the basis of embodiment 1, a protective shell 21 is covered above the starting end 151, as Figure 7 Figure 8 As shown, there is a starting hole 211 on the protective shell 21, the starting hole 211 is facing the top of the starting end 151, and a shielding piece 22 for blocking the starting hole 211 is hinged inside the protective shell 21, and the second pull wire is connected to the end of the shielding piece 22. 23. The other end of the second pull wire 23 passes through the protective case 21 and is connected to the gear shifter of the locomotive. This improvement mainly focuses on the restriction on the starting end 151, because the pretensioning end 101 is the process of tightening the scroll spring 7, and the starting end 151 is the process of releasing the elastic potential energy of the scroll spring 7, so as long as the starting end 151 Install a protective shell 21 additionally. When the ...

Embodiment 3

[0049] like Figure 10 As shown, two pin shafts 24 are fixedly installed on the end face of the ratchet 5, and the two pin shafts 24 are symmetrical to the center of the ratchet 5, and two circles symmetrical to the center of the driven gear 4 are arranged on the end face of the driven gear 4. Arc groove 41, two pin shafts 24 that ratchet 5 passes are embedded in corresponding arc groove 41, and the center angle of arc groove 41 is 80 °, and ratchet 5 is provided with torsion spring, can conveniently like this Pawl 5 returns under the effect of torsion spring.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com