Vehicle oil-way anti-freezing device and method using water temperature of engine heat radiator

An antifreeze device and engine technology, applied in engine cooling, engine components, machines/engines, etc., can solve problems such as increased internal volume of locomotives, achieve the effects of reducing carbon particles and black smoke, saving time, and protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with embodiment the present invention is further described.

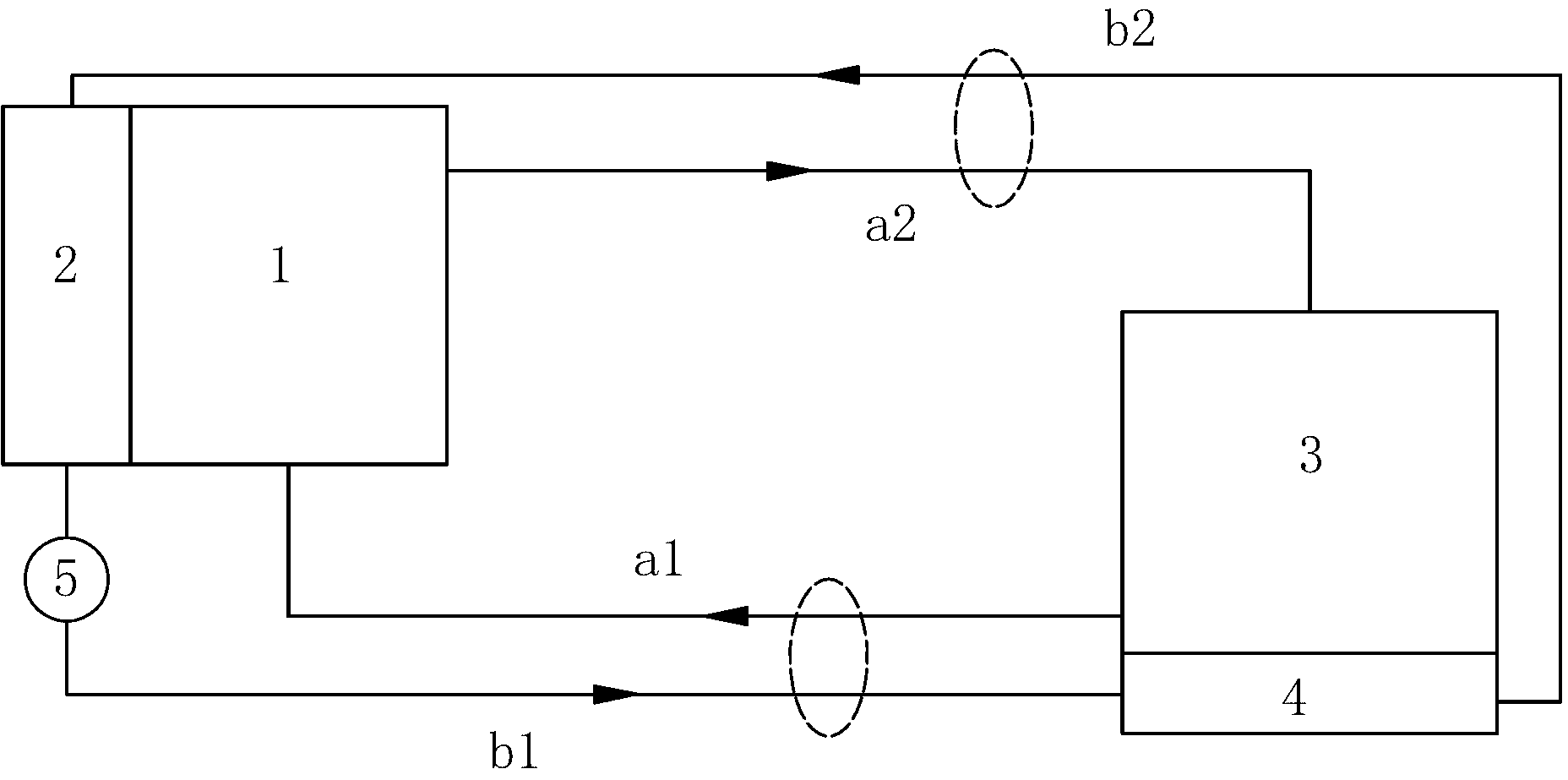

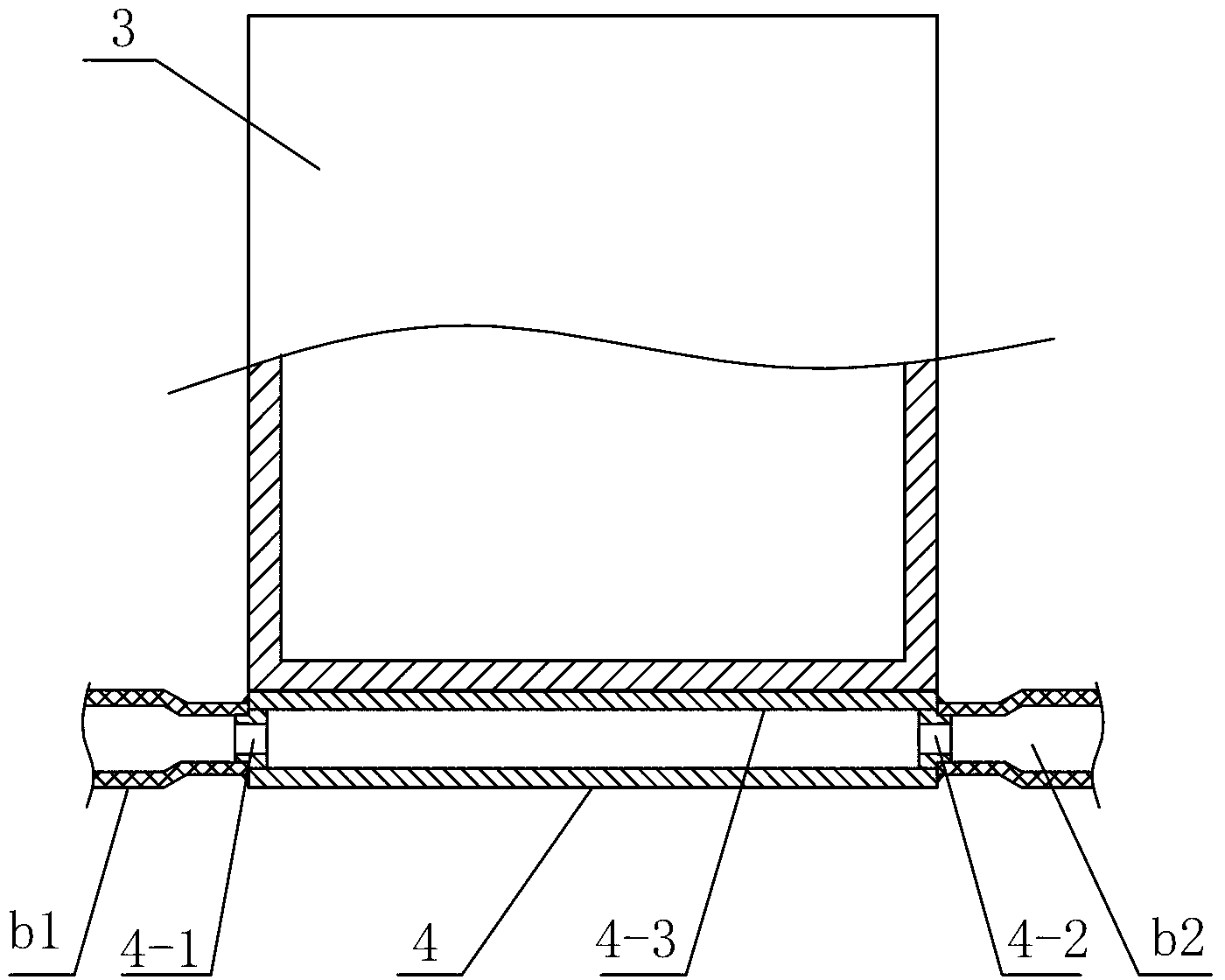

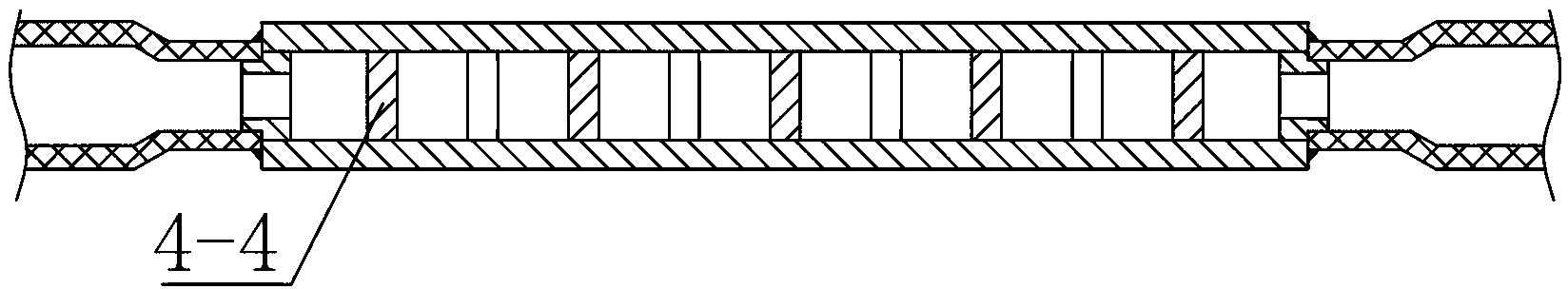

[0032] A vehicle oil circuit antifreeze device utilizing engine radiator water temperature, which includes an engine 1 and a fuel tank 3, an oil inlet pipe a1 and an oil return pipe a2 are connected between the engine 1 and the fuel tank 3, a radiator 2 is mounted on the engine 1, The heat preservation water tank 4 is fixed on the fuel tank 3, and the fixing method can be welding, plugging, flange connection, bolt connection and the like. There is a heat exchange plate 4-3 on the heat preservation water tank 4 which is in close contact with the oil tank 3. There is a water inlet 4-1 and a water outlet 4-2 on the heat preservation water tank 4, and the water inlet 4-1 is connected to the radiator 2. There is a water inlet pipe b1, a return pipe b2 is connected between the water outlet 4-2 and the radiator 2, and the shape of the heat preservation water tank 4 matches the shape of the fuel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com