Method and device for quickly determining gas pressure of coal bed in downward superdeep borehole

A technology for rapid measurement of coal seam gas pressure, which is used in surveying, earth-moving drilling, wellbore/well components, etc. The effect of reducing gas leakage, high accuracy and speeding up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

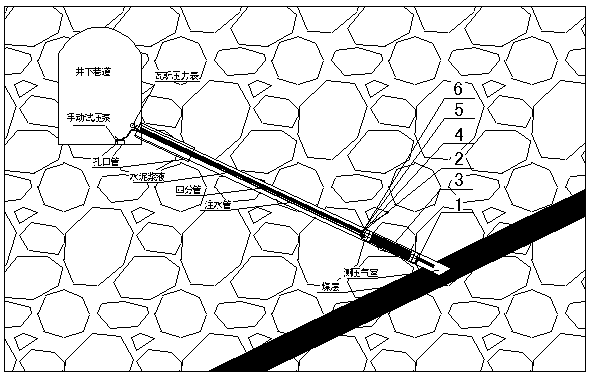

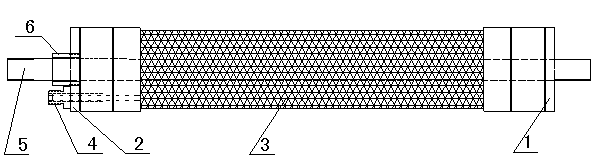

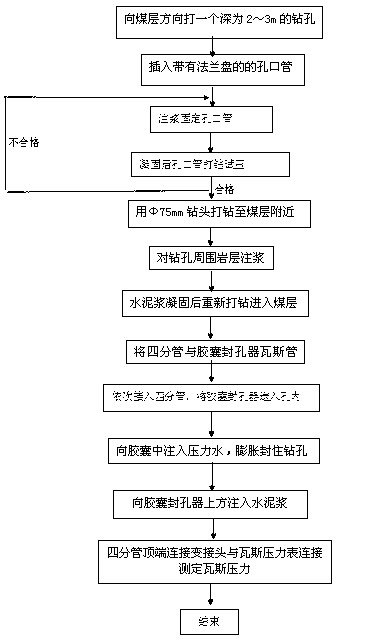

[0031] Such as figure 1 , figure 2 As shown, the method for quickly measuring the coal seam gas pressure in the descending ultra-deep drilling of the present invention, before measuring the coal seam gas pressure, high-pressure grouting is carried out on the rock layer above the measured coal seam, which can improve the compactness of the rock layer and can seal Groundwater, to prevent groundwater pressure from affecting the measurement of coal seam gas pressure, the specific steps are as follows:

[0032] Step 1: Drill a borehole with a diameter of 120-150mm and a depth of 2-3m in the direction of the coal seam in the roadway above the descending coal seam as a pressure measurement hole, and feed an orifice pipe with a diameter of 115×5mm into the borehole. The exposed length of the mouth pipe is 200 ~ 300mm; with a high pressure flange

[0033] Step 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com