Super-long-span cylindrical shell lattice structure construction method

A technology of grid structure and construction method, applied in building construction, construction, construction material processing and other directions, can solve the problems of long construction period, high cost, multiple safety and adverse factors of auxiliary installation equipment, etc., to save installation period, The effect of saving installation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

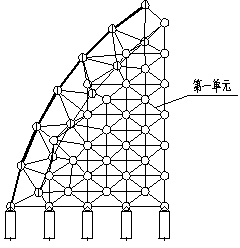

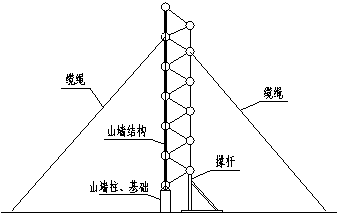

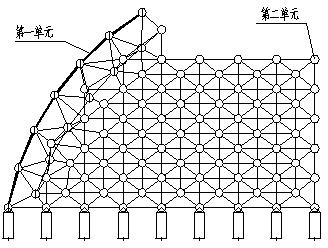

[0043] Such as Figure 1-8 shown.

[0044] A construction method for a super-large-span cylindrical shell grid structure, the key technology of which is to first install the gable grid structure at one end of the cylindrical shell structure, and use the gable grid structure as a stable "starting unit" for the installation of the entire cylindrical shell structure, and then use the existing The installed "stable starting unit", that is, the gable grid structure, bears the construction load. From the gable along the longitudinal direction of the shell structure, the "high-altitude bulk method" is used to complete the installation of the subsequent shell grid structure.

[0045] Specific steps are as follows:

[0046] (1) Construction preparation

[0047] 1. On-site basic handover and acceptance

[0048] 1.1 Measure and accept the completed concrete fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com