Medical digital paper photographic film and preparation method thereof

A paper and film technology, applied in the field of medical consumables, can solve the problems of difficult natural degradation, low clarity and gray scale, high cost, etc., to reduce the use of precious metal silver, improve clarity and gray scale, Effect of film cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

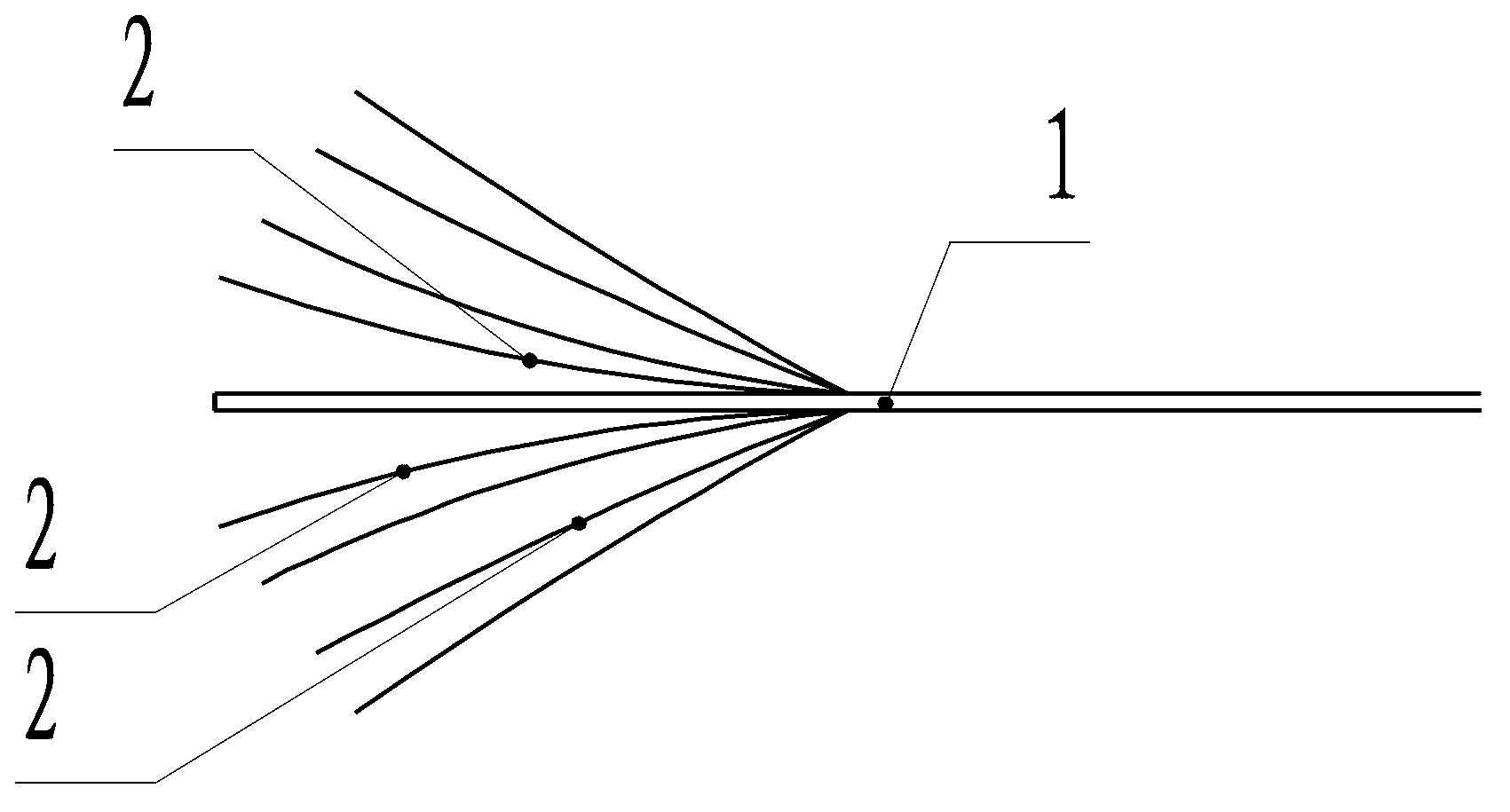

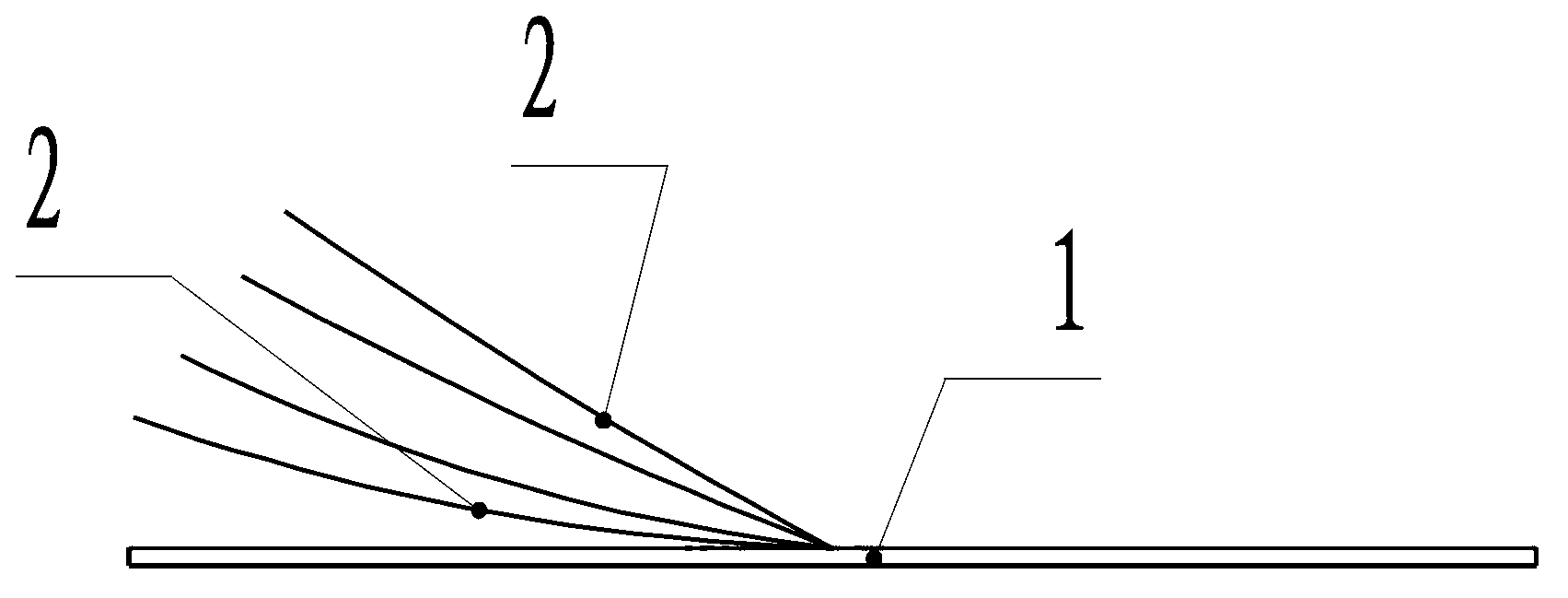

Image

Examples

Embodiment 1

[0016] A method for preparing the medical digital paper film, selects double-sided plastic-coated and coated photo paper bottom paper, and performs three-time single-sided wet coating of aluminum oxide powder on a multi-segment extrusion coating machine. The mechanical speed It is 40m / min, the uniformity of gluing is ±0.025mm, the temperature is controlled at 60±3 degrees Celsius, the temperature is controlled in sections, and the hot air stove is used for heating.

Embodiment 2

[0018] A method for preparing the medical digital paper film, selecting double-sided plastic-coated film photo paper bottom paper, performing double-sided four-time wet coating of aluminum oxide powder on a multi-stage extrusion coating machine, and mechanical The speed is 50m / min, the gluing uniformity is ±0.025mm, the temperature is controlled at 60±3 degrees Celsius, the temperature is controlled in sections, and the hot air stove is used for heating.

Embodiment 3

[0020] A method for preparing the medical digital paper film, selecting double-sided plastic-coated film photo paper bottom paper, performing double-sided three-time wet coating of aluminum oxide powder on a multi-stage extrusion coating machine, and mechanical speed It is 45m / min, the uniformity of gluing is ±0.025mm, the temperature is controlled at 60±3 degrees Celsius, the temperature is controlled in sections, and the hot air stove is used for heating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com