Method for recycling iron from waste red mud in alumina production

A technology for recovering iron and alumina, which is applied to the improvement of process efficiency, details of furnaces and blast furnaces, etc., can solve the problems of low thermal efficiency of electric furnace ironmaking, unfavorable comprehensive utilization of tailings, and low grade of iron concentrate, achieving significant economic and Social benefit, production realization, good pig iron quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

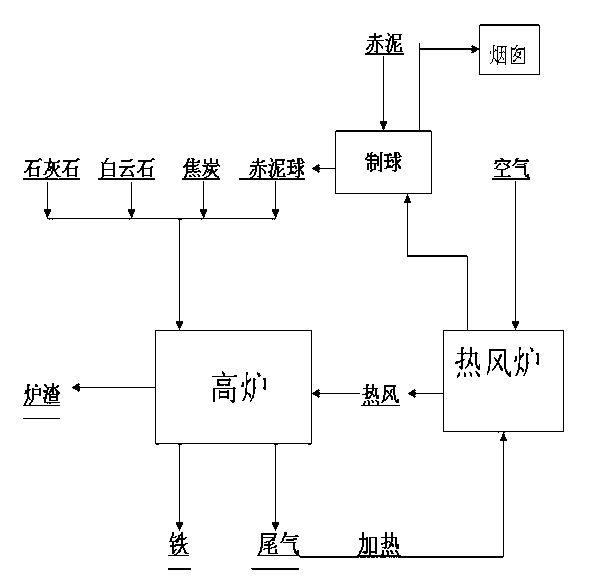

Image

Examples

Embodiment 1

[0024] The solid waste red mud produced by alumina is dried, and the dried red mud is crushed, the particle size is ≤0.15mm, the water content is 1-2%, and the red mud pellets of ? Exhaust gas is used to dry the red mud balls until the water content is less than or equal to 1%. The dry red mud balls are mixed with coke, limestone and dolomite according to the following ratio: red mud 60kg, coke 30kg, limestone 5kg, dolomite 3kg, directly add into the blast furnace, and at the same time, the blower blows air into the blast furnace. The air passes through the hot blast stove and heats the air to 450°C, so that the smelting temperature in the blast furnace reaches 1500-1650°C, and the temperature of slag and iron is 1400-1450°C. The obtained product Pig iron and slag will be comprehensively utilized in the future.

[0025] After testing, the obtained metallic iron is of good quality, including Fe: 94.164%, C: 3.86%, Si: 0.36%, Mn: 0.11%, P: 0.025%, S: 0.054%.

[0026] The analys...

Embodiment 2

[0027] Example 2, the solid waste red mud produced by alumina is dried, the water content is 9-10%, the dried red mud is crushed, the particle size is ≤0.15mm, and the red mud pellets of ?30 are obtained through 50kN pressure. The tail gas of the blast furnace ironmaking is dried to the red mud balls until the water content is ≤1%, and the dry red mud balls are mixed with coke, limestone and dolomite according to the following ratio: 80kg red mud, 20kg coke, 10kg dolomite, directly Add it into the blast furnace, and at the same time blow air into the blast furnace from the blower. The air passes through the hot blast stove and heats the air to 1100°C, so that the smelting temperature in the blast furnace reaches 1500-1650°C, and the temperature of slag and iron is 1400-1480°C. carry out subsequent comprehensive utilization.

[0028] After testing, the obtained metallic iron is of good quality, including Fe: 94.164%, C: 3.82%, Si: 0.41%, Mn: 0.41%, P: 0.087%, S: 0.052%.

[002...

Embodiment 3

[0030] Example 3, the solid waste red mud produced by alumina is dried, the water content is 5-6%, the dried red mud is crushed, the particle size is ≤0.15mm, and red mud pellets of ?15 are obtained through 70kN pressure. The tail gas of the blast furnace ironmaking is dried to the red mud balls until the water content is ≤1%, and the dry red mud balls are mixed with coke, limestone and dolomite iron ore according to the following ratio: red mud 30kg, coke 25kg, iron ore 40kg of limestone and 10kg of limestone are directly added to the blast furnace, and at the same time, the blower blows air into the blast furnace. 1400~1450℃, the slag will be used for subsequent comprehensive utilization.

[0031] After testing, the obtained metallic iron is of good quality, including Fe: 94.98%, C: 3.82%, Si: 0.25%, Mn: 0.65%, P: 0.065%, S: 0.032%.

[0032] The analysis result of the slag is: Fe 2 o 3 : 0.83%, TiO 2 : 4.32%, CaO: 20.67%, SiO 2 : 19.42%, Al 2 o 3 : 28.25%, Na 2 O: 3....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com