Electron beam modification method for reducing rolling resistance of tire tread rubber material and improving abrasion resistance

A tire tread and rolling resistance technology, applied in the field of electron beam modification, can solve the problems such as the degree of chemical pre-vulcanization is not clearly stated and difficult, and achieve rolling resistance reduction, accurate surface modification degree, and control surface modification degree Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

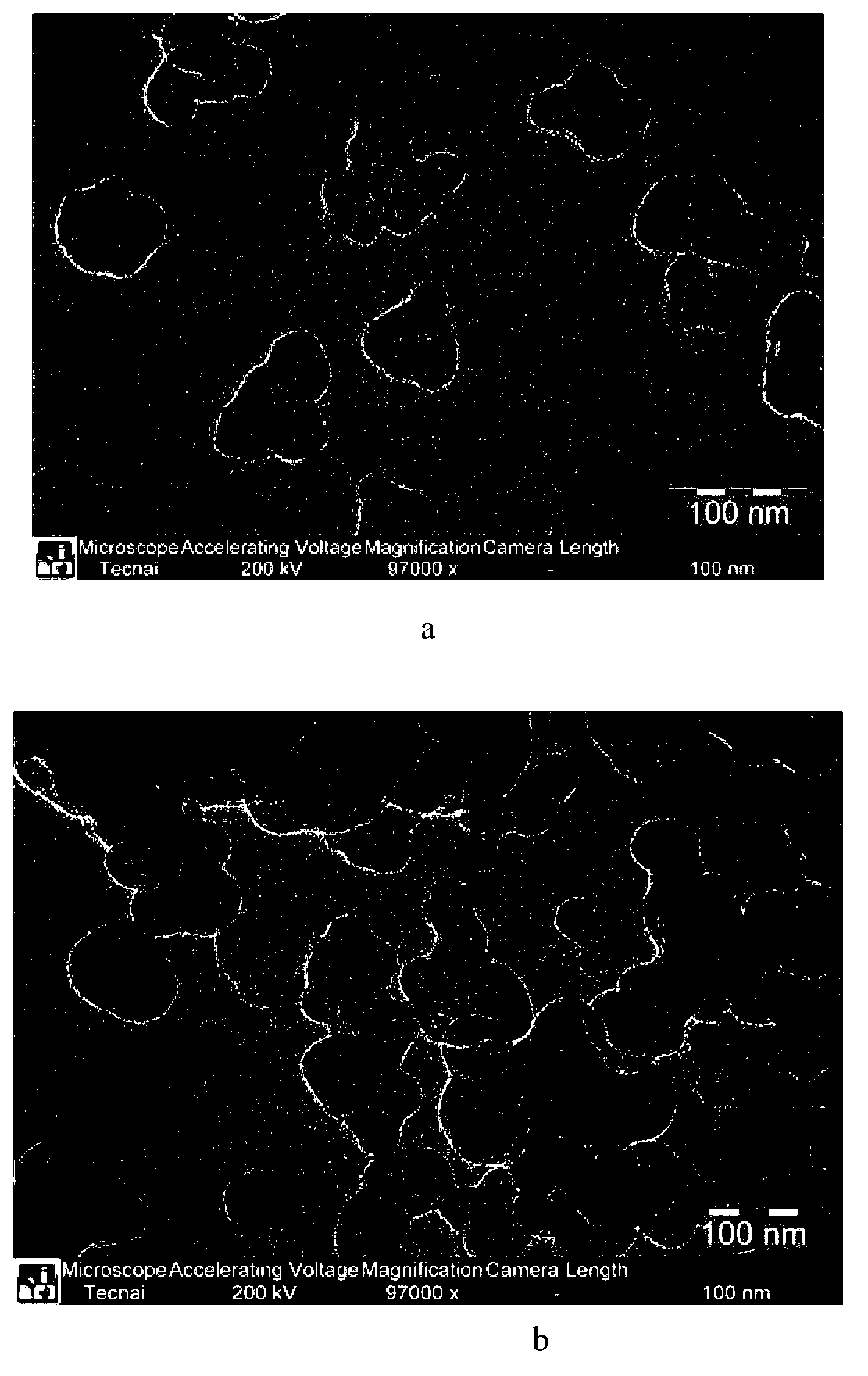

Image

Examples

Embodiment 1

[0022] The formula of the tread rubber in this example is: natural rubber 70phr, styrene-butadiene rubber 30phr, zinc oxide 3phr, stearic acid 3phr, anti-aging agent 4010NA2phr, anti-aging agent RD2phr, solid paraffin 1.5phr, carbon black (N330) 50phr, promote Agent CZ1.1phr, accelerator D0.3phr, sulfur 0.5.

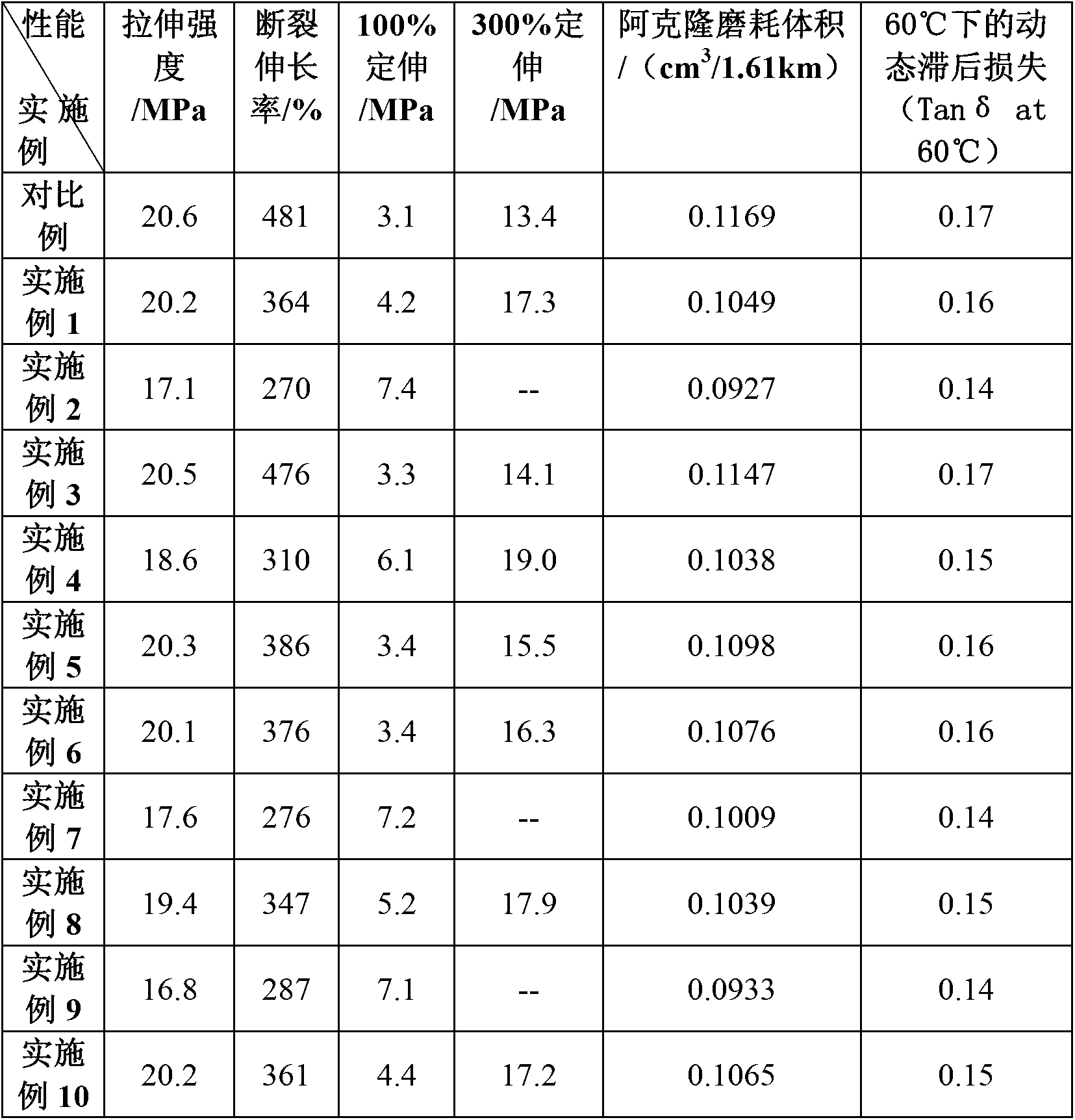

[0023] The tire tread rubber vulcanizate is placed on the conveyor belt, and the conveyor belt passes through the scanning window of the electron beam accelerator installed in the irradiation chamber to complete the irradiation of the vulcanizate. When the vulcanizate passes under the scanning window of the electron accelerator, the irradiation temperature is 30°C, normal pressure, air atmosphere, the number of irradiations is 5 times, the accelerating voltage is 5MeV, the beam intensity is 30mA, and the irradiation dose is 100kGy. The speed is 80m / min. Various performance tests were carried out according to national standards. The physical and mechanical performance pa...

Embodiment 2

[0025] The formula of the tread rubber in this example is: natural rubber 70phr, styrene-butadiene rubber 30phr, zinc oxide 3phr, stearic acid 3phr, anti-aging agent 4010NA2phr, anti-aging agent RD2phr, solid paraffin 1.5phr, carbon black (N330) 50phr, promote Agent CZ1.1phr, accelerator D0.3phr, sulfur 0.5.

[0026] The tire tread rubber vulcanizate is placed on the conveyor belt, and the conveyor belt passes through the scanning window of the electron beam accelerator installed in the irradiation chamber to complete the irradiation of the vulcanizate. When the vulcanizate passes under the scanning window of the electron accelerator, the irradiation temperature is -10°C, normal pressure, air atmosphere, the number of irradiations is 100 times, the accelerating voltage is 2MeV, the beam intensity is 100mA, and the irradiation dose is 600kGy. The passing speed is 200m / min. Various performance tests were carried out according to national standards. The physical and mechanical p...

Embodiment 3

[0028] The formula of the tread rubber in this example is: natural rubber 70phr, styrene-butadiene rubber 30phr, zinc oxide 3phr, stearic acid 3phr, anti-aging agent 4010NA2phr, anti-aging agent RD2phr, solid paraffin 1.5phr, carbon black (N330) 50phr, promote Agent CZ1.1phr, accelerator D0.3phr, sulfur 0.5.

[0029] The tire tread rubber vulcanizate is placed on the conveyor belt, and the conveyor belt passes through the scanning window of the electron beam accelerator installed in the irradiation chamber to complete the irradiation of the vulcanizate. When the vulcanizate passes under the scanning window of the electron accelerator, the irradiation temperature is 100°C, normal pressure, nitrogen atmosphere, the number of irradiation is 1 time, the accelerating voltage is 1MeV, the beam intensity is 0.001mA, and the irradiation dose is 0.001kGy , The passing speed is 0.001m / min. Various performance tests were carried out according to national standards. The physical and mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com