A kind of intumescent flame retardant and preparation method thereof

An intumescent flame retardant and catalyst technology, applied in the field of flame retardants and their preparation, can solve the problems of limited quantity, poor polymer compatibility, inability to effectively overcome heat resistance, etc., and achieves short synthesis cycle and raw material source. Rich and good interface binding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

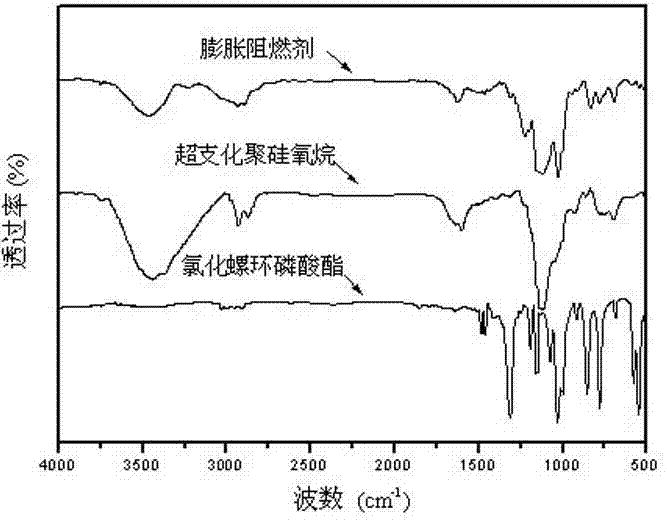

[0029] 1. Synthesis of chlorinated spirocyclic phosphate

[0030] Under nitrogen protection, 13.6 g of pentaerythritol was added into 90 mL of phosphorus oxychloride, and the temperature was gradually raised to 80° C. for 8 h. After the reaction, wash with carbon tetrachloride and ethanol three times in sequence, filter with suction, and dry in vacuum to obtain a white powder product with a yield of 81.5%.

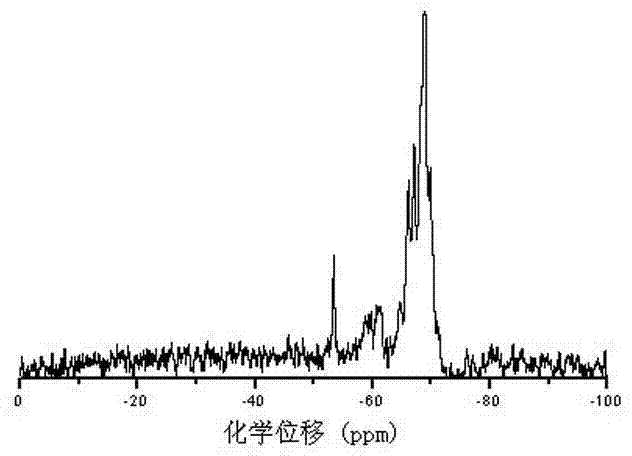

[0031] 2. Synthesis of amino group-containing hyperbranched polysiloxane

[0032] Under nitrogen protection and normal temperature, add 9g of deionized water, 50mL of ethanol and 0.5mL of tetraethylammonium hydroxide (20% aqueous solution) into a 250mL reactor, and stir to obtain a uniform mixed solution. 22.1 g of γ-aminopropyltriethoxysilane was added dropwise to the reactor using a constant pressure dropping funnel, and the dropwise addition was completed within 10 minutes. After raising the temperature to 50° C. for 10 hours, hexamethyldisilane was added into the rea...

Embodiment 2

[0057] 1. Synthesis of chlorinated spirocyclic phosphate

[0058] Under the protection of nitrogen, 6.8g of pentaerythritol was added into 45mL of phosphorus oxychloride, and then the temperature was gradually raised to 80°C for 8h. After the reaction, wash with carbon tetrachloride and ethanol three times successively, filter with suction, and dry in vacuum to obtain a white powder product with a yield of 79.5%.

[0059] 2. Synthesis of amino group-containing hyperbranched polysiloxane

[0060] Under nitrogen protection, at room temperature, add 18g of deionized water, 50mL of methanol and 1mL of tetraethylammonium hydroxide (20% aqueous solution) into a 250mL reactor, and stir to obtain a uniform mixture. 44.2 g of γ-aminopropyltriethoxysilane was added dropwise to the reactor using a constant pressure dropping funnel, and the dropwise addition was completed within 10 minutes. After reacting at 50°C for 12 hours, add the end-capping agent hexamethyldisilane into the reacto...

Embodiment 3

[0064] 1. Synthesis of chlorinated spirocyclic phosphate

[0065]Under the protection of nitrogen, 13.6g of pentaerythritol was added into 45mL of phosphorus oxychloride, and then the temperature was gradually raised to 80°C for 8h. After the reaction, wash with carbon tetrachloride and ethanol three times successively, filter with suction, and dry in vacuum to obtain a white powder product with a yield of 69.7%.

[0066] 2. Synthesis of amino group-containing hyperbranched polysiloxane

[0067] Under nitrogen protection, add 4.5g of deionized water, 50mL of ethanol and 0.5mL of tetramethylammonium hydroxide (20% aqueous solution) into a 250mL reactor, and stir to obtain a uniform mixture. Add 11 g of γ-aminopropyltriethoxysilane dropwise into the three-necked flask using a constant pressure dropping funnel, and the dropwise addition is completed within 10 minutes. After reacting at 50°C for 10 hours, add the end-capping agent hexamethyldisilane into the reactor, and continu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

| Branching factor | aaaaa | aaaaa |

| Branching factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com