Alpha-Fe2O3 nanometer sphere preparation method

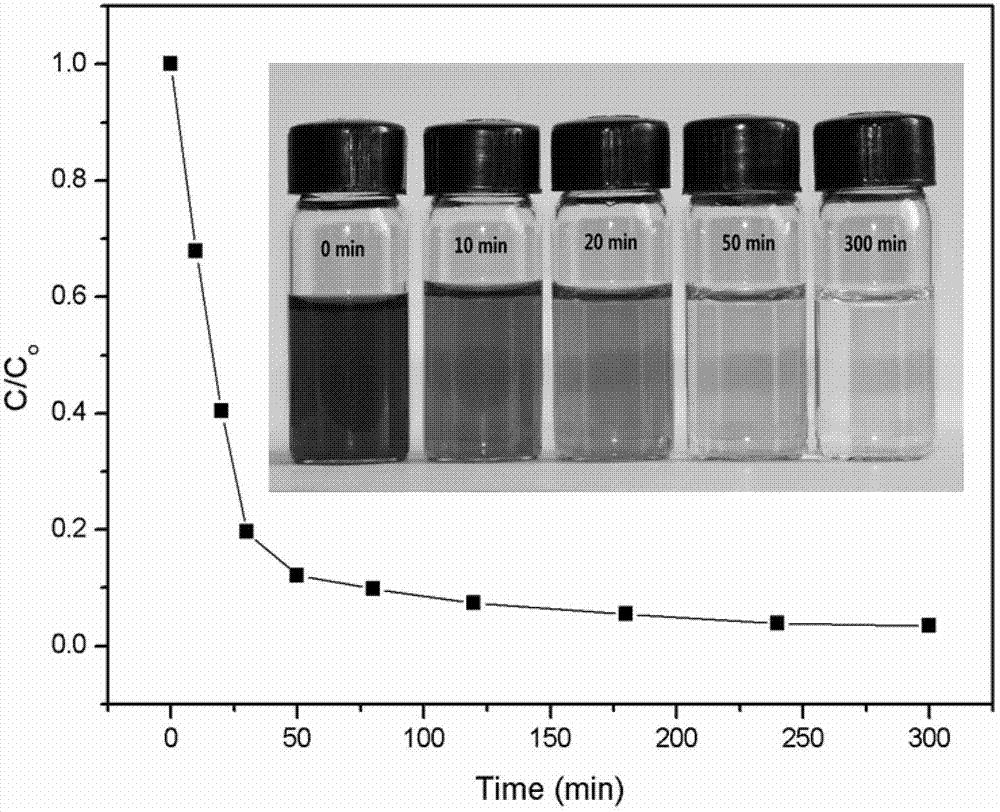

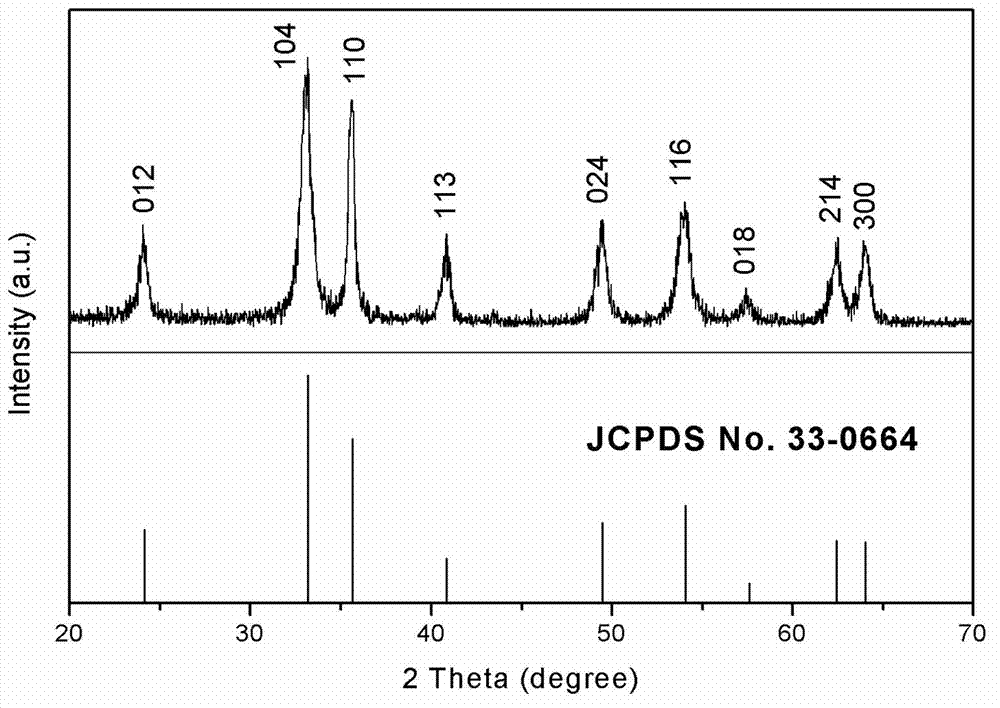

A technology of nanospheres, fecl3 6h2o, applied in the field of chemical engineering, to achieve good adsorption, energy saving, and short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] 1) Ferric chloride hexahydrate (FeCl 3 ·6H 2 O) is the iron source, urea (CO(NH 2 ) 2 ) Is a hydroxide ion initiator with a molar ratio of 1:1. The iron source and initiator are dissolved in a mixed solvent composed of glycerin and water using ultrasound. The concentration of iron source is 1.0 mol / L, and the volume ratio of glycerin and water is 1:9. The mixed solution was placed in a polytetrafluoroethylene reactor and sealed, transferred to a microwave reactor, and subjected to microwave treatment at a temperature of 150° C. for 30 min.

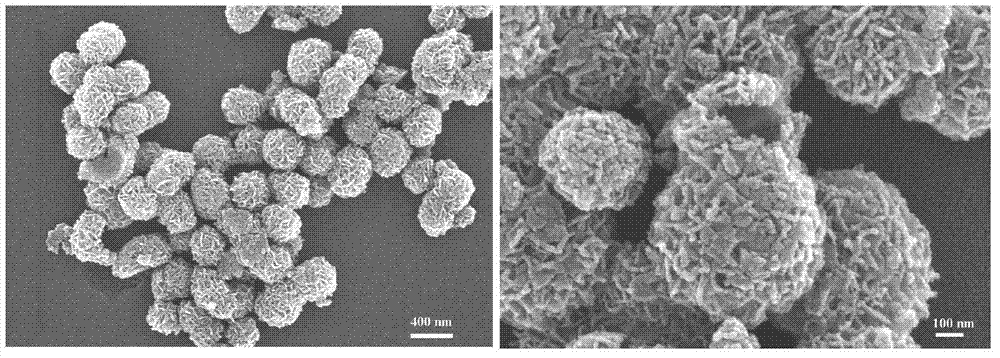

[0040] 2) The product after the above microwave treatment is naturally cooled and centrifuged at 10,000 rpm for 30 minutes. The resulting precipitate is washed alternately with ethanol and water, washed and dried at 80°C for 5 hours to obtain solid nanospheres with an average diameter of 300-350 nm. The overall structure It is composed of rod-shaped nano subunits with a size of 20-50nm, such as image 3 Shown.

[0041] by image 3 The s...

Embodiment 2

[0043] 1) Ferric chloride hexahydrate (FeCl 3 ·6H 2 O) is the iron source, urea (CO(NH 2 ) 2 ) Is a hydroxide ion initiator with a molar ratio of 1:1. The iron source and initiator are dissolved in a mixed solvent composed of glycerin and water using ultrasound. The concentration of iron source is 1.0 mol / L, and the volume ratio of glycerol and water is 1:6. The mixed solution was placed in a polytetrafluoroethylene reactor and sealed, transferred to a microwave reactor, and subjected to microwave treatment at 140° C. for 30 min.

[0044] 2) The product after the above microwave treatment is naturally cooled and centrifuged at 10,000 rpm for 30 minutes. The resulting precipitate is washed alternately with ethanol and water, washed and dried at 80°C for 5 hours to obtain semi-solid nanospheres with an average diameter of 350-400 nm. The structure is composed of rod-shaped nano subunits with a size of 20-50nm, such as Figure 4 Shown.

[0045] by Figure 4 It is clearly visible that...

Embodiment 3

[0047] 1) Ferric chloride hexahydrate (FeCl 3 ·6H 2 O) is the iron source, urea (CO(NH 2 ) 2 ) Is a hydroxide ion initiator with a molar ratio of 1:1.5. The iron source and the initiator are dissolved in a mixed solvent composed of glycerin and water using ultrasound. The concentration of iron source is 1.0 mol / L, and the volume ratio of glycerin and water is 1:3. The mixed solution was placed in a polytetrafluoroethylene reactor and sealed, transferred to a microwave reactor, and subjected to microwave treatment at 140° C. for 30 min.

[0048] 2) After the above microwave treatment, the product is naturally cooled and centrifuged at 10,000 rpm for 30 minutes. The resulting precipitate is washed alternately with ethanol and water, washed and dried at 80°C for 5 hours to obtain hollow nanospheres with an average diameter of 300-400 nm, hollow spherical shells The thickness is about 60nm. Its overall structure is composed of rod-shaped nano subunits with a size of 30-50nm, such as...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com