Preparation method of acid-modified superfine shell powder and product

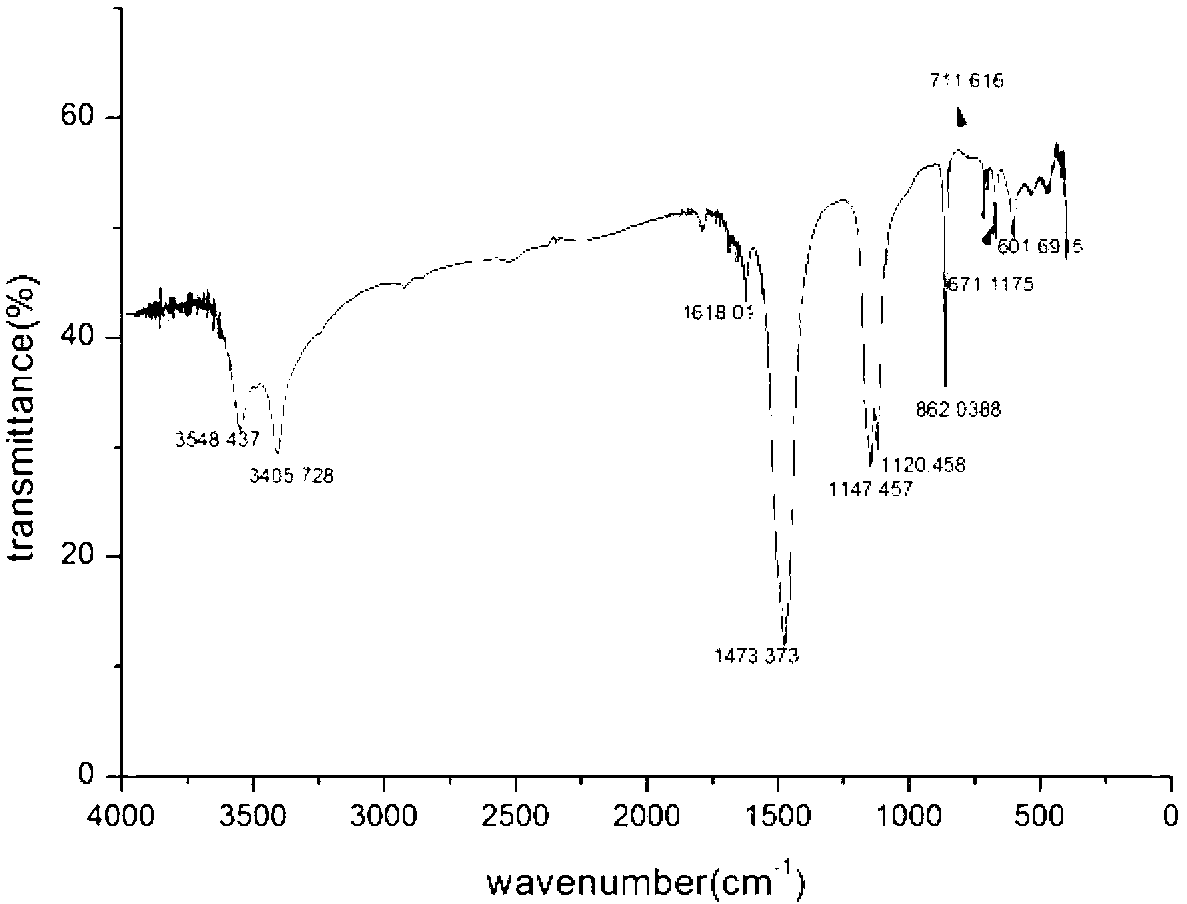

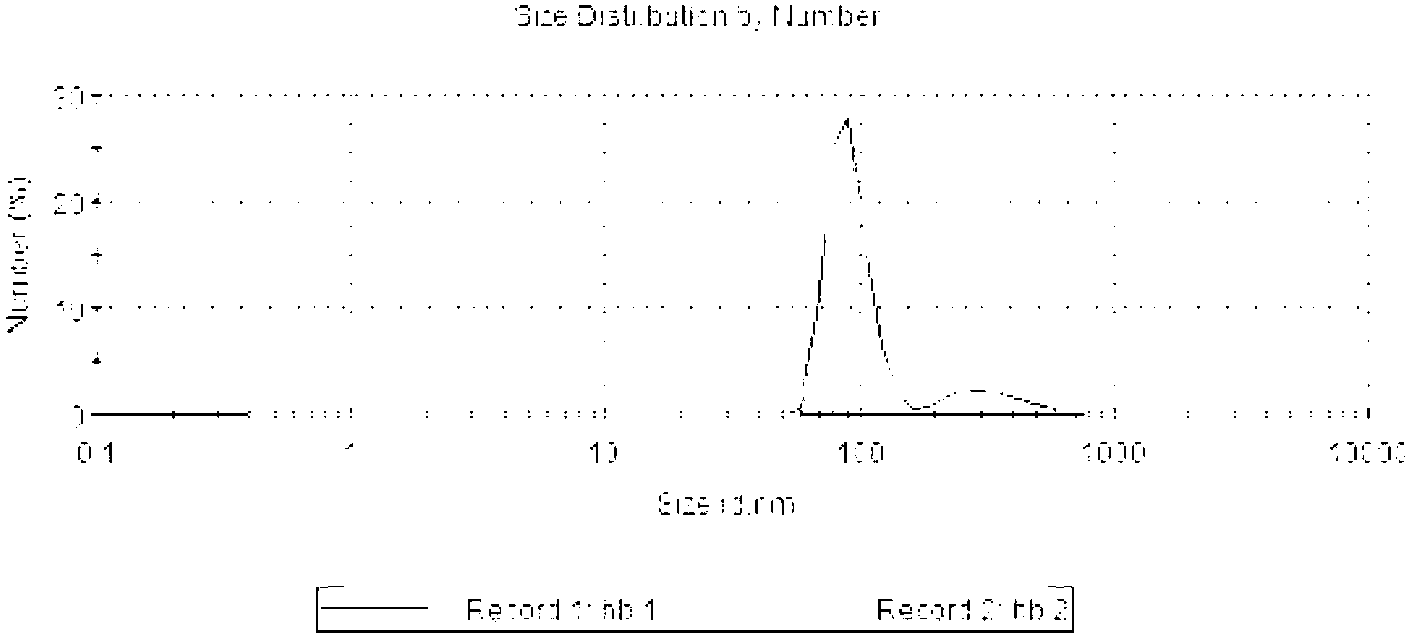

A shell powder, acid modification technology, applied in the direction of calcium carbonate/strontium/barium, etc., can solve the problems of complex production process, few applications, high cost, and achieve the effects of good surface activity, simple process and sufficient raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 1) Soak the mussel shell raw material in 4% alkali hydroxide for 24 hours at a temperature of 80° C. to remove the cuticle, and wash it with water until neutral to obtain the shell with the cuticle, and then divide the weight of the shell equivalent to the cuticle 80% of the water was added into the ball mill, and the ball mill was stirred for 48 hours to obtain a slurry;

[0032] 2) Slowly add 10% concentrated hydrochloric acid, which is equivalent to 25% of the exfoliated shell weight, to the slurry several times, stirring constantly, and the reaction time is 6 hours;

[0033] 3) Washing the acid-modified shell micropowder slurry, press filtering, drying and pulverizing to obtain modified shell powder with a particle size of 0.5-5 μm;

[0034] 4) Add 20% pure water equivalent to the weight of the modified shell powder to the modified shell powder, and adjust it into a paste, and then use the planetary ball mill to grind it, dry and grind it to obtain superfine powder ...

Embodiment 2

[0036] 1) Soak the mussel shell raw material in 0.1% alkali hydroxide for 24 hours at a temperature of 20° C. to remove the cuticle, and wash with water until neutral to obtain a shell with the cuticle, and then put the shell equivalent to the cuticle by 20 % of water was added to the ball mill, and the ball mill was stirred for 6 hours to obtain a slurry;

[0037] 2) Slowly add sulfuric acid of 1% concentration, which is equivalent to 5% of the exfoliated shell weight, to the slurry several times, stir constantly, and the reaction time is 0.5h;

[0038] 3) Washing the acid-modified shell micropowder slurry, press filtering, drying and pulverizing to obtain modified shell powder with a particle size of 0.5-5 μm;

[0039] 4) Add 5% pure water equivalent to the weight of the modified shell powder into the modified shell powder, and adjust it into a paste, and then use the planetary ball mill to process it, dry and grind it to obtain superfine powder with a particle size of 0.01-...

Embodiment 3

[0041] 1) Soak the scallop shell raw material in 10% alkali hydroxide for 24 hours at a temperature of 20° C. to remove the cuticle, and wash with water until neutral to obtain a shell with the cuticle, and then 80 % of water was added to the ball mill, and the ball mill was stirred for 48 hours to obtain a slurry;

[0042] 2) Slowly add 10% formic acid with a concentration of 25% to the weight of exfoliated shells into the slurry several times, stir constantly, and the reaction time is 6 hours;

[0043] 3) Washing the acid-modified shell micropowder slurry, press filtering, drying and pulverizing to obtain modified shell powder with a particle size of 0.5-5 μm;

[0044] 4) Add 10% pure water equivalent to the weight of the modified shell powder to the modified shell powder, and adjust it into a paste, and then use the planetary ball milling method to process, dry and pulverize to obtain superfine powder with a particle size of 0.01-5 μm shell powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com