Processing technology for enhanced spiral rib enhanced steel plastic composite pipe

A technology of composite processing and spiral ribs, which is applied in the processing technology field of spiral rib reinforced steel-plastic composite pipes, can solve the problem of low ring stiffness and mechanical strength, low axial and radial tensile and compressive strength of pipes, and difficult to bear Tension and bending moments and other issues, to achieve reliable product quality, reasonable production process design, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

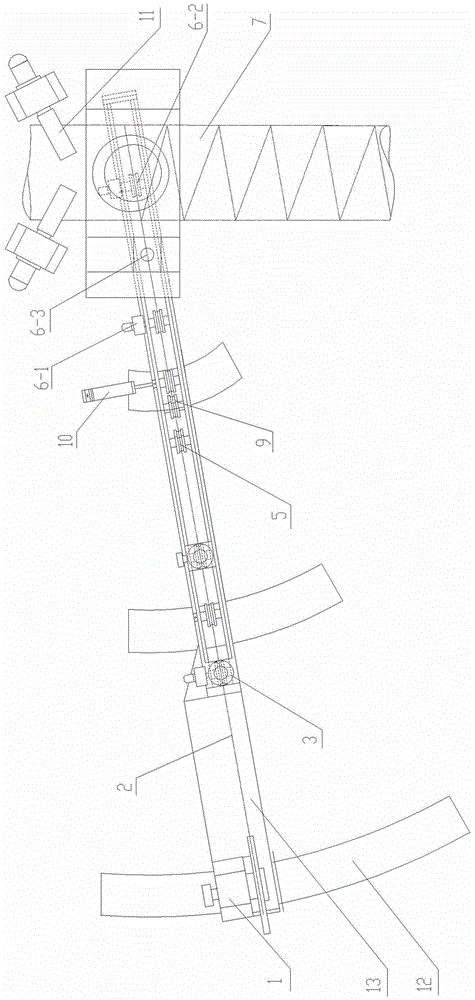

[0019] The invention provides a processing technology of spiral rib reinforced thin-walled steel-plastic composite pipe, including shaping of the reinforcing rib, guiding the shaped reinforcing rib in place, and welding composite positioning of the thin-walled steel pipe, see figure 1 with figure 2 , including the following steps:

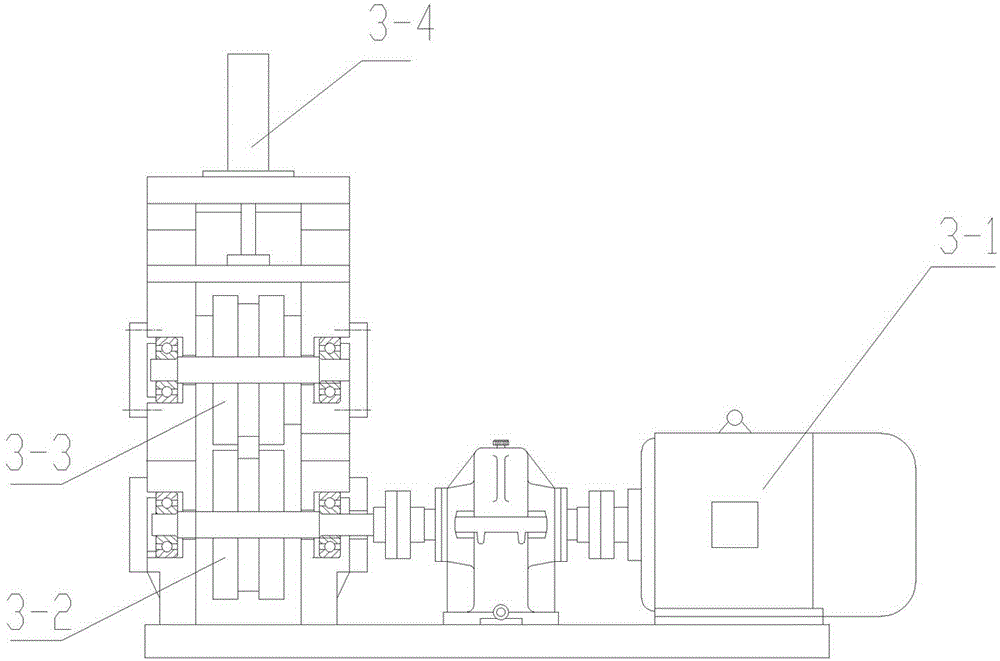

[0020] Step a. Uncoil the selected reinforcing ribs according to the design requirements: including the azimuth angle of the reinforcing rib conveying direction and the thin-walled steel pipe rotation direction determined by the helix angle of the reinforcing ribs, and adjust the reinforcing rib conveying form and feeding line speed to meet the design After the requirement, the quenching and tempering pretreatment process is introduced; the uncoiling of the reinforcing ribs uses the uncoiling mechanism 1, and the structure of the uncoiling mechanism includes a motor with a reducer and a main shaft connected to the motor by means of a transmission ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com