Preparation of Xanthogenic Acidified Loess Adsorbent and Its Application in Wastewater Treatment

A xanthogenation and adsorbent technology, which is applied in the fields of adsorption water/sewage treatment, water/sewage treatment, water/sludge/sewage treatment, etc. and other problems, to achieve the effect of being conducive to environmental protection, causing secondary pollution, and good adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

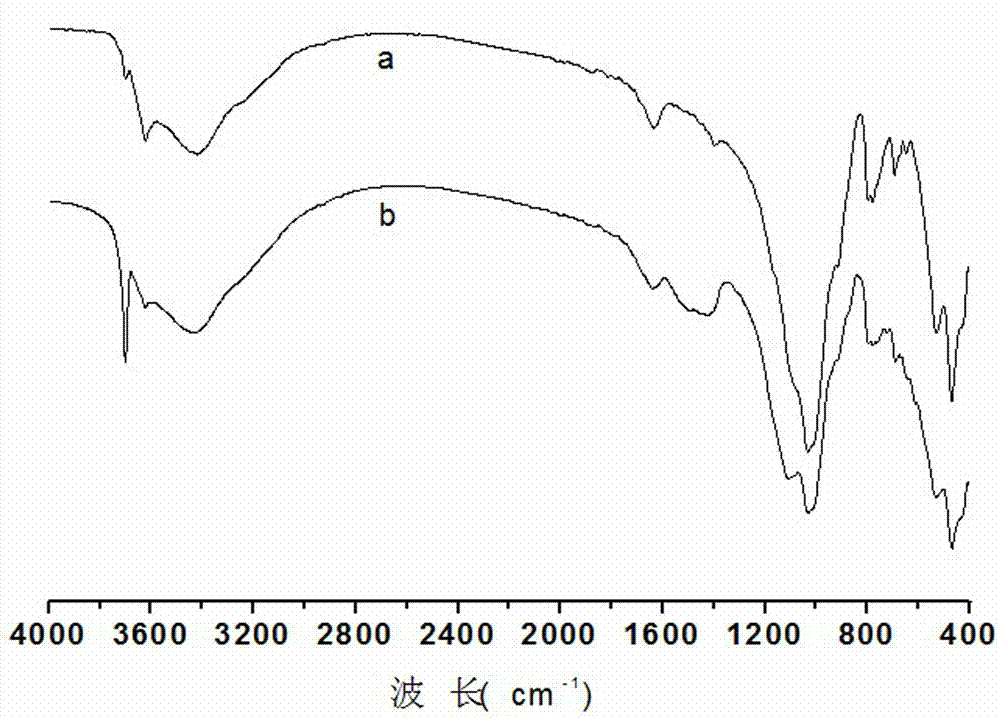

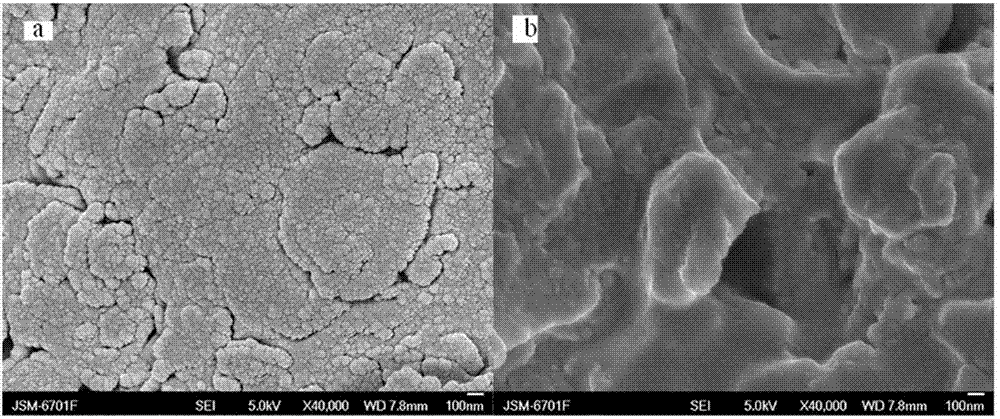

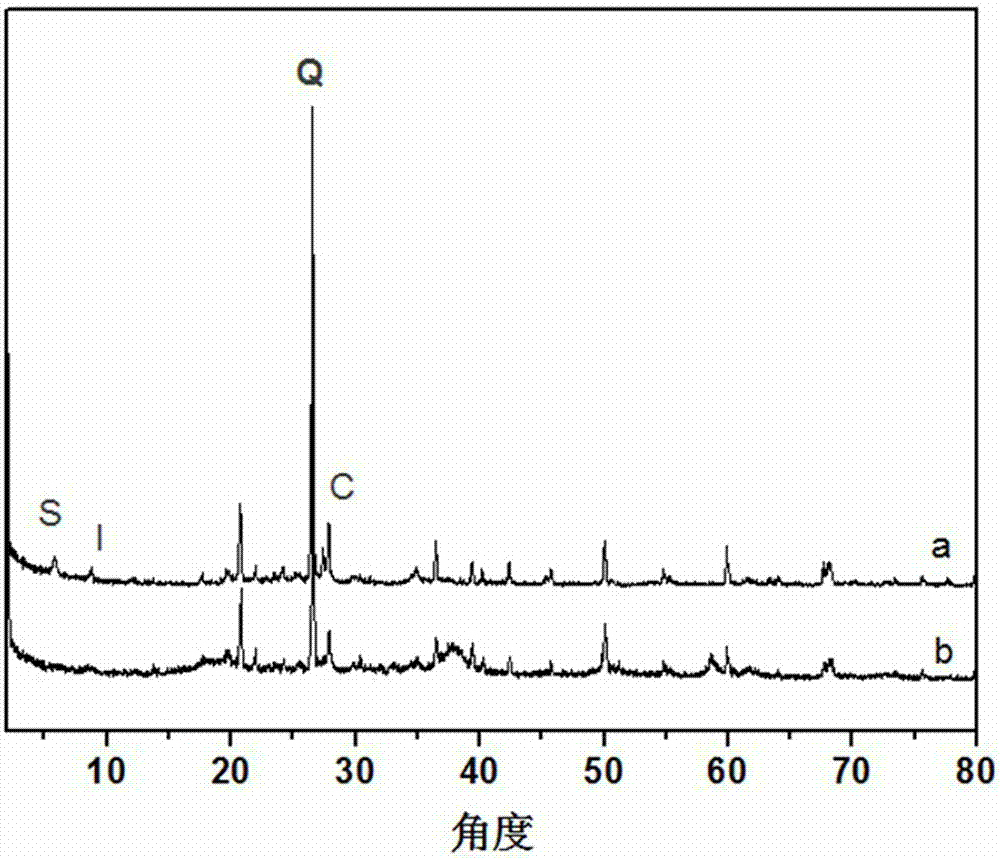

[0035] (1) Preparation of xanthated loess adsorbent

[0036] Disperse the loess in a 5% sodium hydroxide solution with a solid-to-liquid mass ratio of 1:1, and stir at a constant temperature of 35°C for 1 h to form a suspension; add 0.1 times the weight of loess to the system dropwise , and reacted at 35°C for 1 h to form sodium salt of xanthan acidified loess; prepared a solution with a mass fraction of 10% of magnesium sulfate twice the mass of loess, added it to the system, and continued to react at 35°C for 0.5 h to form Magnesium salt of xanthated loess; repeated washing and suction filtration with 10% magnesium sulfate solution by mass fraction until the filtrate was colorless, then washed with acetone, dried in vacuum, and ground into powder to obtain xanthated loess adsorbent (XLC ).

[0037] (2) Determination of adsorption performance

[0038] Adsorption experiment of heavy metal copper ions by xanthan acidified loess adsorbent: [Cu II ]: 100 mg / L, pH=4.7, the amou...

Embodiment 2

[0041] (1) Preparation of xanthated loess adsorbent

[0042] The loess was dispersed in a 30% sodium hydroxide solution with a solid-to-liquid mass ratio of 1:1, and stirred at a constant temperature at 10°C for 3 h to form a suspension; 0.3 times the amount of loess was added dropwise to the system. React at 10°C for 6 h to form sodium salt of xanthogenic acidified loess; prepare a solution with a mass fraction of 15% of magnesium sulfate that is three times the mass of loess, add it to the system, and continue to react at 45°C for 2 h to form yellow loess. Magnesium salt of ortho-acided loess; add 5% magnesium sulfate solution to wash repeatedly, filter with suction until the filtrate is colorless, then wash with acetone, dry in vacuum, grind into powder, and obtain xanthated loess adsorbent (XLC).

[0043] (2) Determination of adsorption performance:

[0044] Adsorption experiment of heavy metal copper ions by xanthan acidified loess adsorbent: [Cu II ]: 100 mg / L, pH=4.7,...

Embodiment 3

[0047] (1) Preparation of xanthated loess adsorbent

[0048] The loess was dispersed in a 10% sodium hydroxide solution with a solid-to-liquid mass ratio of 1:3, and stirred at a constant temperature at 45 °C for 1 h to form a suspension; 0.5 times the amount of loess was added dropwise to the system. React at 25°C for 0.5 h to form sodium salt of xanthogenic acidified loess; prepare a solution of 5% magnesium sulfate with 4 times the mass of loess, add it to the system, and continue to react at 10°C for 1 h to form yellow Magnesium salt of ortho-acided loess; add 10% magnesium sulfate solution to wash repeatedly, filter with suction until the filtrate is colorless, then wash with acetone, dry in vacuum, grind into powder, and obtain xanthated loess adsorbent (XLC).

[0049] (2) Determination of adsorption performance:

[0050] Adsorption experiment of heavy metal copper ions by xanthan acidified loess adsorbent: [Cu II ]: 100 mg / L, pH=4.7, the amount of adsorbent was 0.05 g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com