Preparation of xanthated loess adsorbent and application of xanthated loess adsorbent to waste water treatment

A technology of xanthification and adsorbent, which is applied in the direction of adsorption of water/sewage treatment, water/sewage treatment, water/sludge/sewage treatment, etc. It can solve the problem of low removal rate of heavy metal copper ion and malachite green, which cannot be used and other problems, to achieve the effect of being beneficial to environmental protection, causing secondary pollution, and large adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

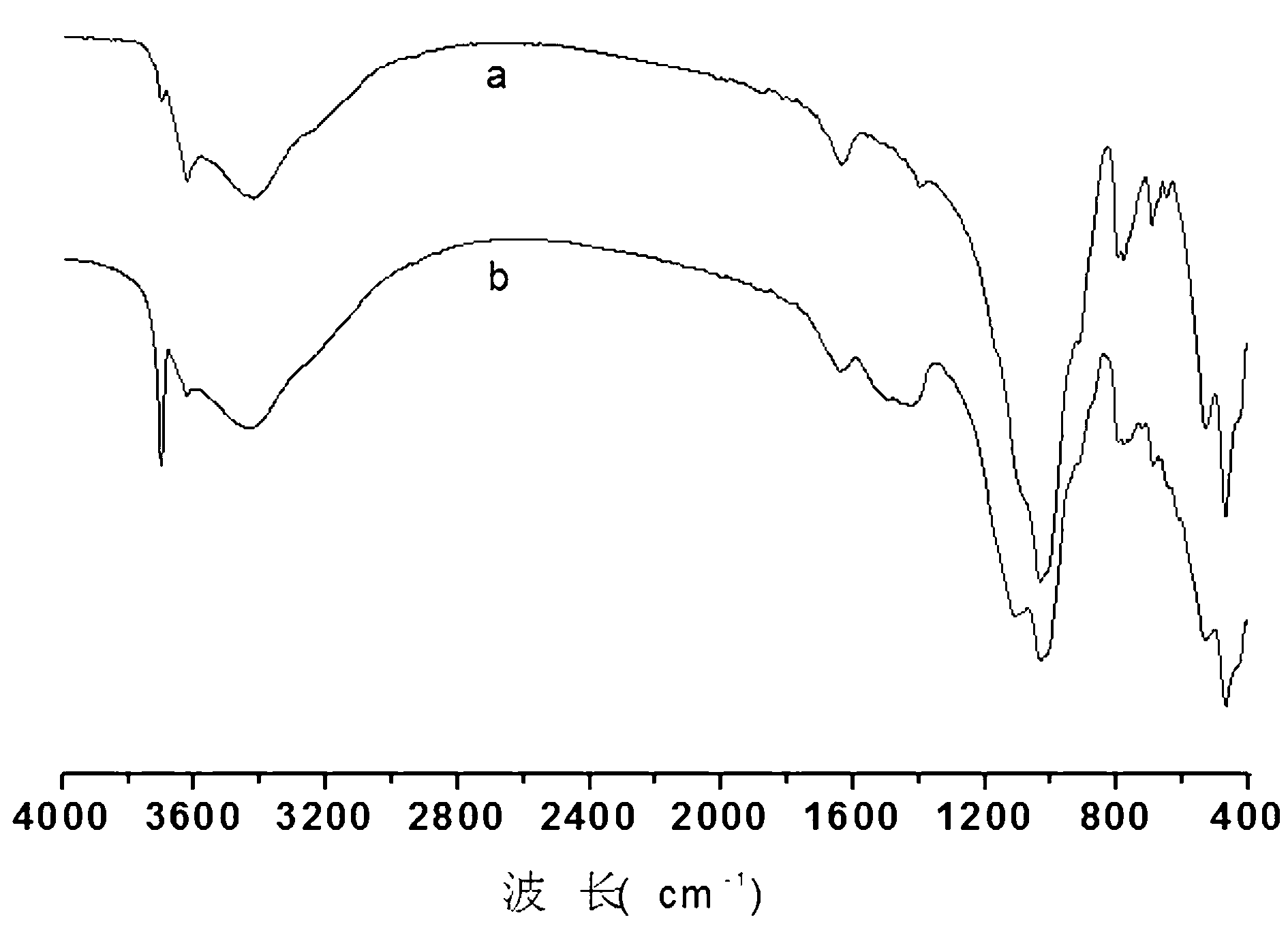

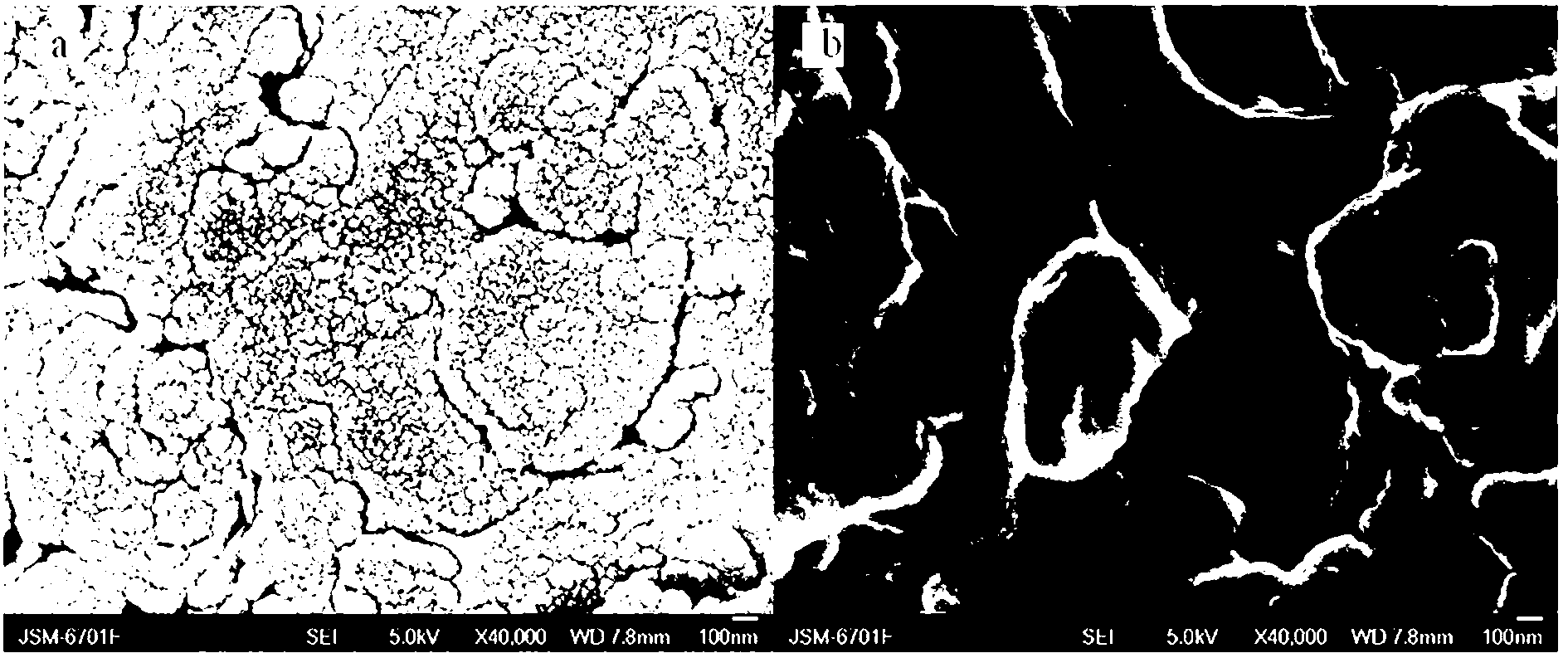

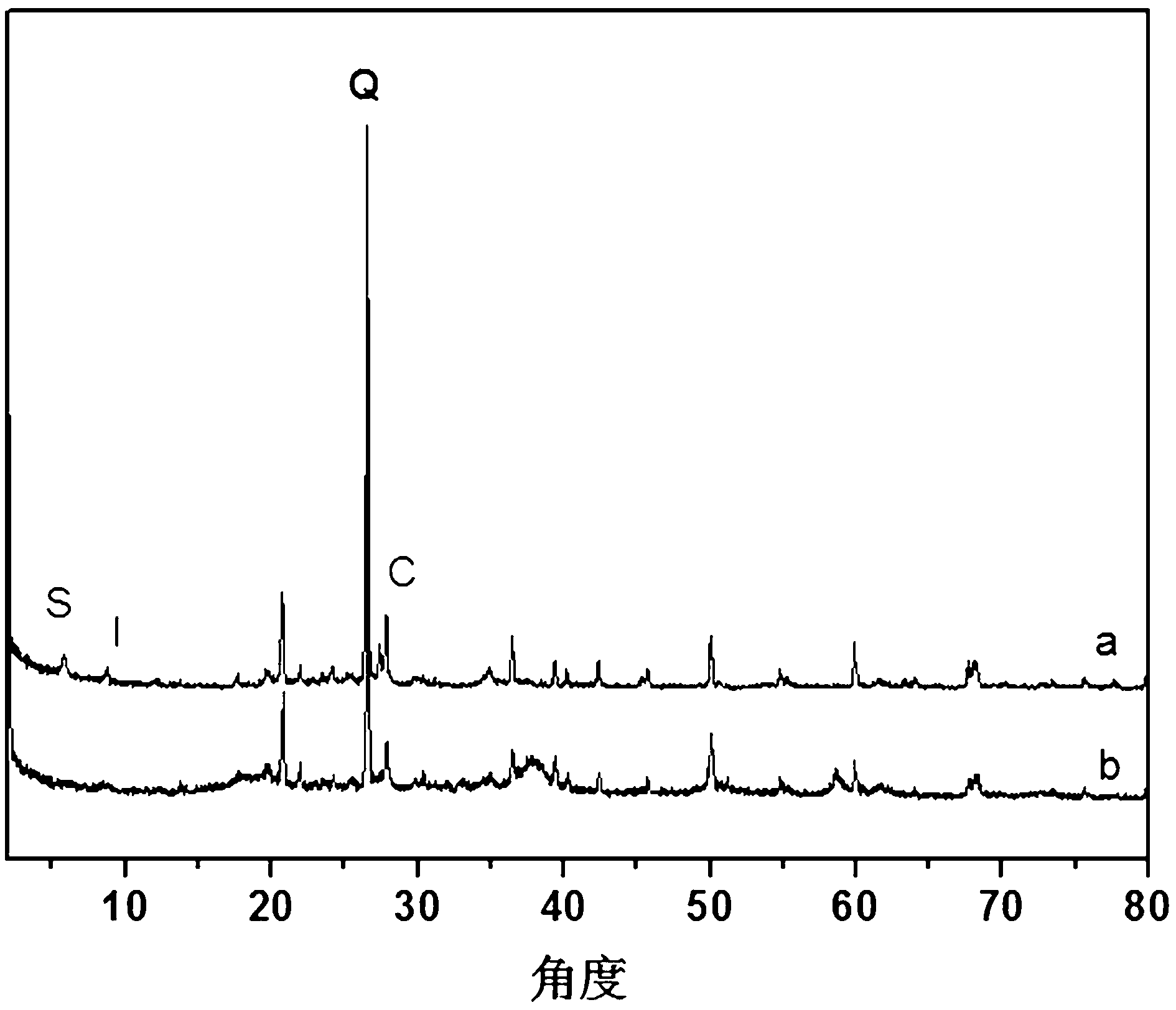

[0035] (1) Preparation of xanthated loess adsorbent

[0036] Disperse the loess in a 5% sodium hydroxide solution with a solid-to-liquid mass ratio of 1:1, and stir at a constant temperature of 35°C for 1 h to form a suspension; add 0.1 times the weight of loess to the system dropwise , and reacted at 35°C for 1 h to form sodium salt of xanthan acidified loess; prepared a solution with a mass fraction of 10% of magnesium sulfate twice the mass of loess, added it to the system, and continued to react at 35°C for 0.5 h to form Magnesium salt of xanthated loess; repeated washing and suction filtration with 10% magnesium sulfate solution by mass fraction until the filtrate was colorless, then washed with acetone, dried in vacuum, and ground into powder to obtain xanthated loess adsorbent (XLC ).

[0037] (2) Determination of adsorption performance

[0038] Adsorption experiment of heavy metal copper ions by xanthan acidified loess adsorbent: [Cu II ]: 100 mg / L, pH=4.7, the amou...

Embodiment 2

[0041] (1) Preparation of xanthated loess adsorbent

[0042] The loess was dispersed in a 30% sodium hydroxide solution with a solid-to-liquid mass ratio of 1:1, and stirred at a constant temperature at 10°C for 3 h to form a suspension; 0.3 times the amount of loess was added dropwise to the system. React at 10°C for 6 h to form sodium salt of xanthogenic acidified loess; prepare a solution with a mass fraction of 15% of magnesium sulfate that is three times the mass of loess, add it to the system, and continue to react at 45°C for 2 h to form yellow loess. Magnesium salt of ortho-acided loess; add 5% magnesium sulfate solution to wash repeatedly, filter with suction until the filtrate is colorless, then wash with acetone, dry in vacuum, grind into powder, and obtain xanthated loess adsorbent (XLC).

[0043] (2) Determination of adsorption performance:

[0044] Adsorption experiment of heavy metal copper ions by xanthan acidified loess adsorbent: [Cu II ]: 100 mg / L, pH=4.7,...

Embodiment 3

[0047] (1) Preparation of xanthated loess adsorbent

[0048] The loess was dispersed in a 10% sodium hydroxide solution with a solid-to-liquid mass ratio of 1:3, and stirred at a constant temperature at 45 °C for 1 h to form a suspension; 0.5 times the amount of loess was added dropwise to the system. React at 25°C for 0.5 h to form sodium salt of xanthogenic acidified loess; prepare a solution of 5% magnesium sulfate with 4 times the mass of loess, add it to the system, and continue to react at 10°C for 1 h to form yellow Magnesium salt of ortho-acided loess; add 10% magnesium sulfate solution to wash repeatedly, filter with suction until the filtrate is colorless, then wash with acetone, dry in vacuum, grind into powder, and obtain xanthated loess adsorbent (XLC).

[0049] (2) Determination of adsorption performance:

[0050] Adsorption experiment of heavy metal copper ions by xanthan acidified loess adsorbent: [Cu II ]: 100 mg / L, pH=4.7, the amount of adsorbent was 0.05 g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com