Method for manufacturing weight gaining fat chicken fodder

A manufacturing method and feed technology, which is applied in the field of feed manufacturing, can solve the problems of long process, drug residues, and many ingredients, and achieve the effects of reducing the number of mixing times, reducing the disease rate, and increasing immunity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

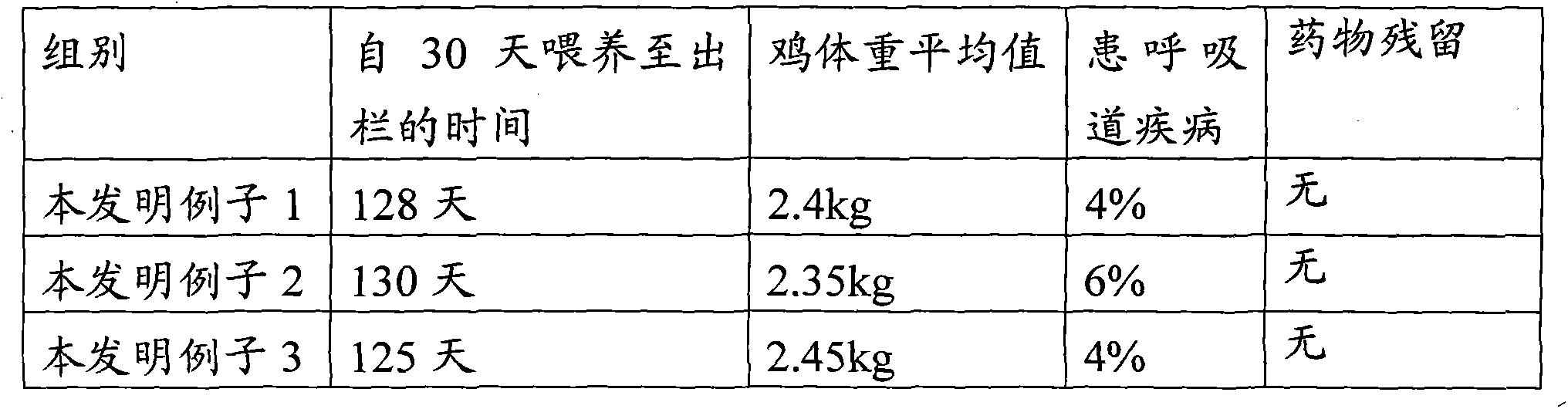

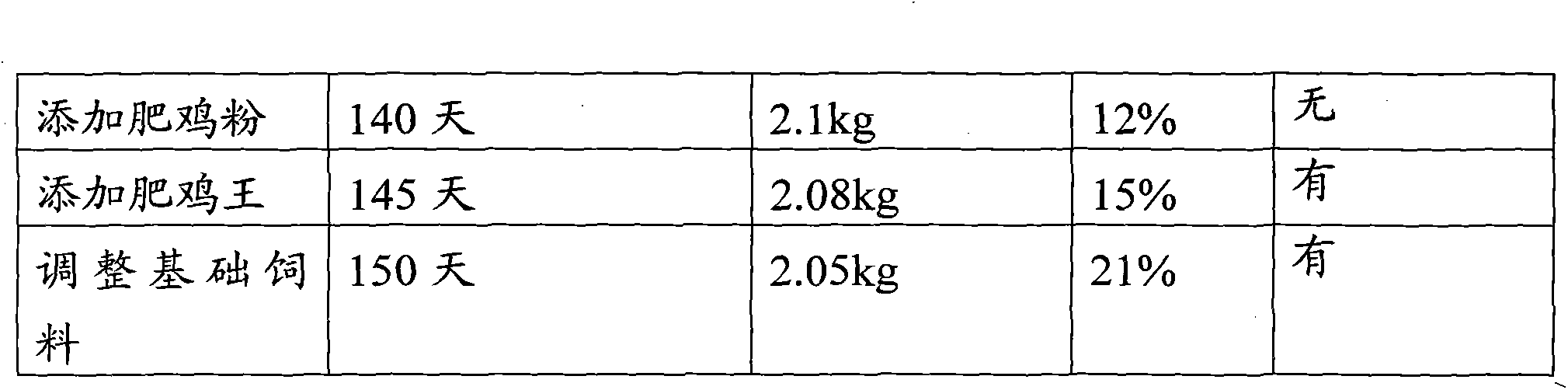

Examples

Embodiment Construction

[0018] Example 1,

[0019] Configure each component of the basic feed according to weight percentage: 60% corn, 4% sorghum, 5% barley, 10% bean cake, 5% fish meal, 3% shell meal or bone meal, 12% animal protein, and 1% salt;

[0020] Configure the components of weight-increasing auxiliary materials according to weight percentage: 30% cinnamon bark, 20% fennel, 10% sand Qiang, 10% tangerine peel, 2% pepper, 2% licorice, 10% Bupleurum, 6% Radix Ophiopogon, 5% angelica %, Scrophulariaceae 5%;

[0021] The ratio of basal feed to supplementary materials for weight gain was

[0022] 30-60 days 99:1;

[0023] 60-90 days 102:1.1;

[0024] 90 days to slaughter 107:1.15.

[0025] During the entire breeding process, only three feed ratio adjustments are needed, and it is a simple mixture of basic feed and weight-increasing auxiliary materials. Save labor intensity, simple and easy to match.

[0026] Example 2

[0027] Configure each component of the basic feed according to weight ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com