Printed circuit comprising at least one ceramic component

A technology of printed circuit boards and components, which is applied in the direction of printed circuits, printed circuits, printed circuits assembled with electrical components, etc., and can solve problems such as increased thermomechanical stress, limitations, and reduced capacitor capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

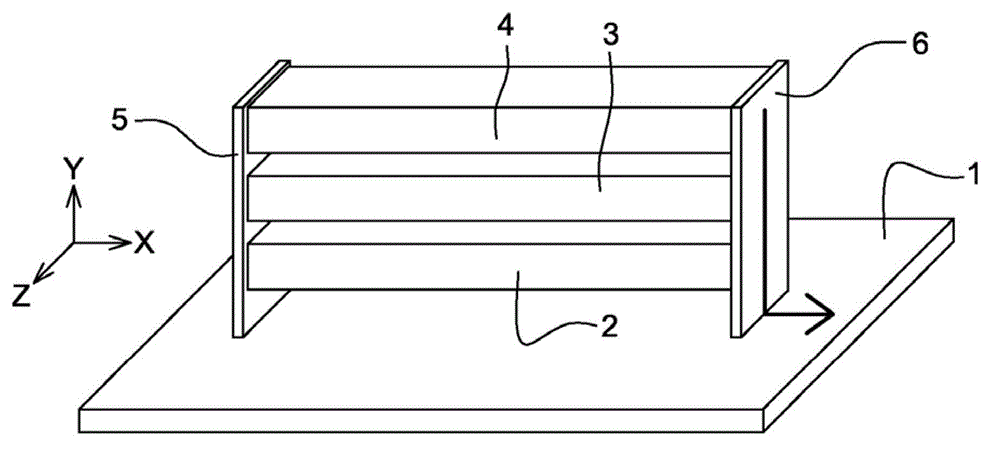

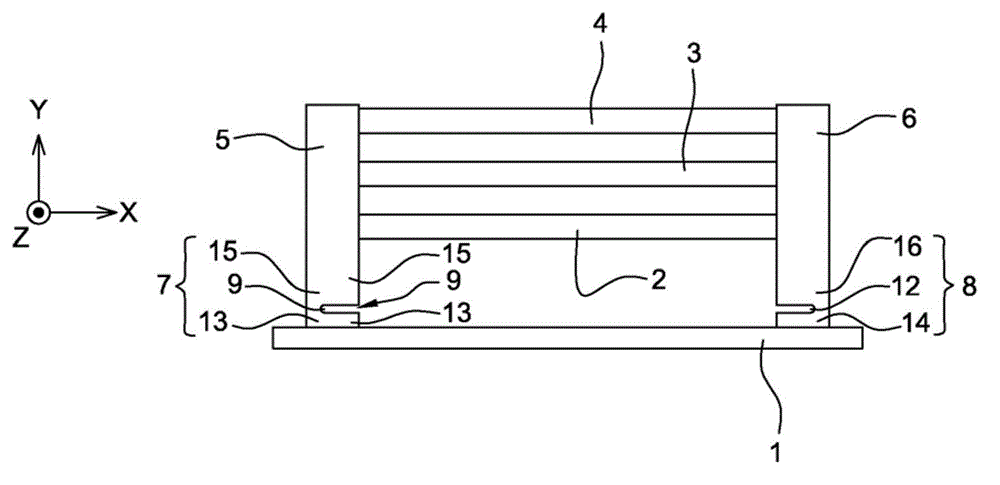

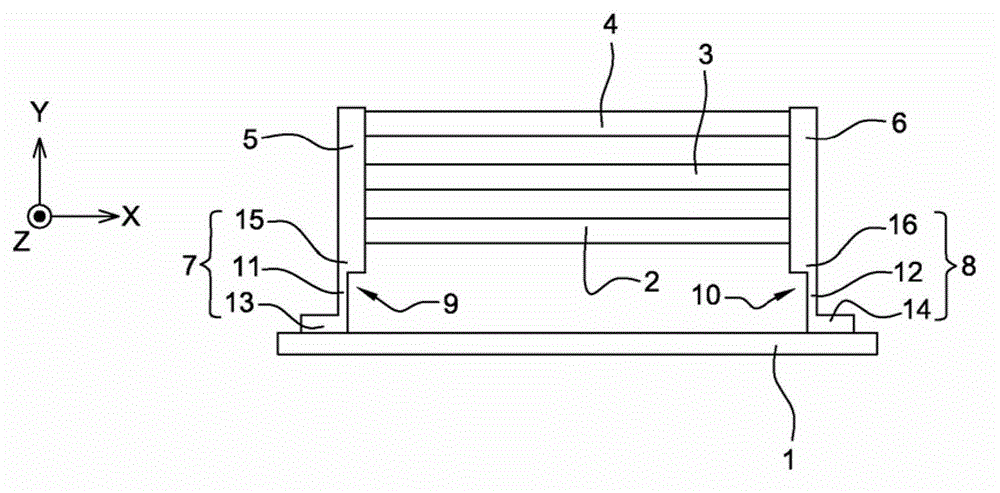

[0047] figure 1 and figure 2 A printed circuit board according to a first embodiment of the present invention is shown. The printed circuit board comprises a substrate (1). The substrate ( 1 ) preferably comprises an assembly of one or more thin copper layers separated by insulating material. The insulating material may be, for example, polyamide, epoxy resin or fiberglass. The substrate (1) typically has a coefficient between 4 and 25 ppm / k.

[0048] The substrate (1) is parallel to the XZ plane.

[0049] The printed circuit board also includes three ceramic components (2, 3, 4) connected in parallel to the base plate (1). In this example, the number of ceramic parts connected in parallel is equal to three, but a different number of ceramic parts can be chosen without departing from the scope of the invention. Typically, a number n of ceramic components can be connected in parallel, where n is 1 or more.

[0050] In this embodiment the ceramic components ( 2 , 3 , 4 ) a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com