Focusing and leveling device

The technology of focusing and leveling device and grating is applied in the direction of exposure device, optics and instrument in photoengraving process, which can solve the problems of difficult installation and adjustment and complicated structure, and achieve the effect of simplifying the difficulty of design and debugging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

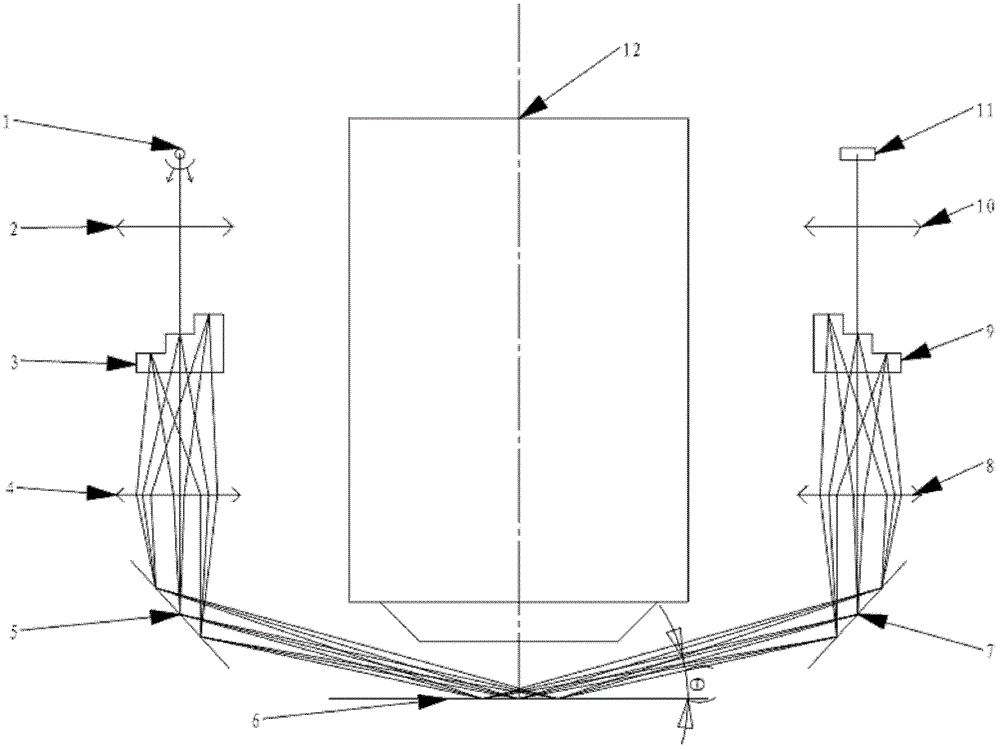

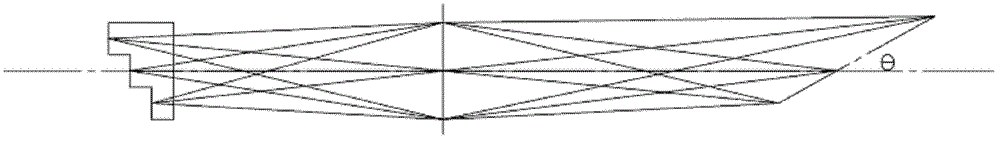

[0011] see figure 1 and figure 2 shown. The focusing and leveling device of the present invention is used on the projection lithography machine 12. The focusing and leveling device includes: an illumination system, an imaging system and a detection system. The feature of the present invention is to use a stepped grating with a height difference as the focusing marks and reference marks.

[0012] The lighting system of the focusing and leveling device is composed of a wide-spectrum light source 1 and a lighting lens 2. The wide-spectrum light source 1 can be composed of a halogen lamp or multiple LEDs. The lighting lens 2 is a Kohler lighting system. In order to obtain a uniform lighting effect, it has a high After being illuminated by the light source, the poor stepped illumination grating 3 is imaged on the silicon wafer 6 through the projection objective lens 4 of the illumination system, reflected by the silicon wafer 6, and then imaged on the reference grating 9 in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com