Solid nitrate ion electrode based on conductive polyaniline and preparing method thereof

A conductive polyaniline and nitrate ion technology, applied in the field of electrochemical detection, can solve the problems of easy signal drift, short service life, large volume, etc., and achieve the effects of avoiding secondary pollution, high sensitivity, and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

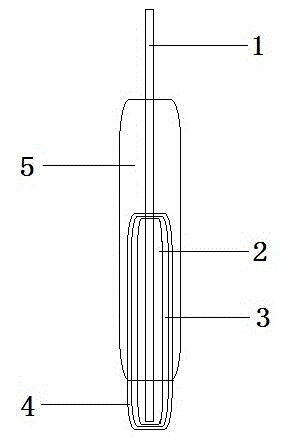

[0036] The steps of the preparation method of the solid nitrate ion electrode based on conductive polyaniline are as follows:

[0037] 1) The metal wire 1 with a length of 5-15 cm is ultrasonically cleaned in acetone solution to remove surface oil, then ultrasonically cleaned in 1-2M dilute hydrochloric acid to remove oxides, then ultrasonically cleaned with deionized water and dried ;

[0038] 2) Prepare 0.5-1M aniline hydrochloride solution with aniline and hydrochloric acid at a molar ratio of 1:1, or dissolve aniline hydrochloride flake solid in deionized water to prepare 0.5-1M aniline hydrochloride solution; The chemical workstation uses cyclic voltammetry to electroplate a layer of conductive polyaniline 2 on the surface of the metal wire 1; among them, the scanning potential is 0-0.45V, the scanning speed is 50mV / s, the sampling interval is 1mV, and the sensitivity is 10 -4 A / V; metal wire 1 is used as anode, the auxiliary electrode is Pt electrode, and the reference ...

Embodiment 1

[0057] 1) The metal wire 1 with a length of 10 cm was ultrasonically cleaned in acetone solution to remove surface oil, then ultrasonically cleaned in 1M dilute hydrochloric acid to remove oxides, then ultrasonically cleaned with deionized water and dried;

[0058] 2) Weigh 1.9439g of commercial aniline hydrochloride flaky solid and dissolve it in 15ml of deionized water to prepare a 1M aniline hydrochloride solution; use CHI760D electrochemical workstation to electroplate a layer of conductive polyaniline on the surface of metal wire 1 by cyclic voltammetry 2;

[0059] The experimental parameters are: scanning potential 0-0.45V, scanning speed 50mV / s, sampling interval 1mV, sensitivity 10 -4 A / V; metal wire 1 is used as anode, the auxiliary electrode is Pt electrode, and the reference electrode is commercial Ag / AgCl electrode; insert the three electrodes into 1M aniline hydrochloride solution at the same time, scan continuously for 20 cycles, and use anhydrous Rinse the elec...

Embodiment 2

[0069] 1) The metal wire 1 with a length of 8 cm was ultrasonically cleaned in acetone solution to remove surface oil, then ultrasonically cleaned in 2M dilute hydrochloric acid to remove oxides, then ultrasonically cleaned with deionized water and dried;

[0070] 2) Weigh 10.1388g of hydrochloric acid and 9.313g of aniline respectively, and add water to the scale in a 100ml volumetric flask to obtain a solution of hydrochloric acid:aniline=1M:1M; Plating a layer of conductive polyaniline 2;

[0071] The experimental parameters are: scanning potential 0-0.45V, scanning speed 50mV / s, sampling interval 1mV, sensitivity 10 -4 A / V; metal wire 1 is used as anode, the auxiliary electrode is Pt electrode, and the reference electrode is commercial Ag / AgCl electrode; insert the three electrodes into 1M aniline hydrochloride solution at the same time, scan continuously for 20 cycles, and use anhydrous Rinse the electrode with alcohol, and use it after the alcohol evaporates;

[0072] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com