A cyclone-type multi-layer air intake hood installed in a biomass combustion furnace

A biomass combustion furnace, cyclone technology, applied in the direction of combustion equipment, lighting and heating equipment, etc., can solve the problems of incomplete combustion, incomplete firepower, insufficient air intake, etc., to reduce carbon emissions, reduce consumption, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

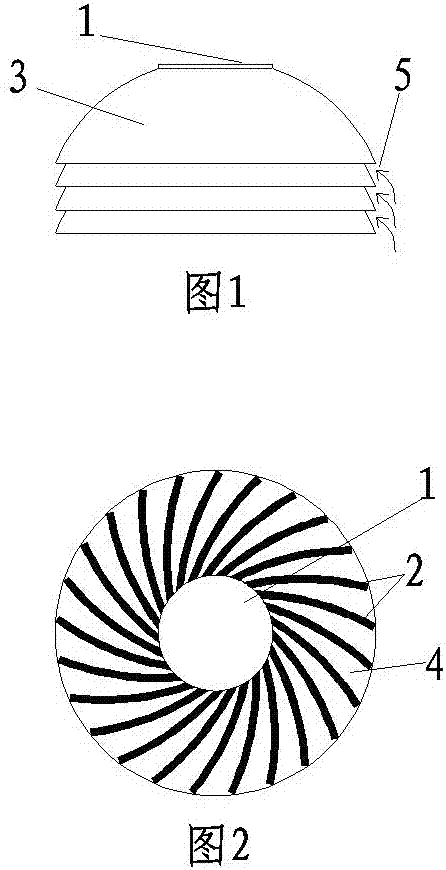

[0012] As shown in Figure 1, a cyclone-type multi-layer intake hood installed in a biomass combustion furnace is formed by overlapping multi-layer masks, the face wall (3) is upward, and a fire hole (1) is provided in the center, and the overlapping masks form multiple layers. Layer air inlet (5), the mask shape is arc mask, cone mask, pyramid mask, ellipse mask, parabolic mask. In order to prevent movement, positioning and fixing are adopted between the masks.

[0013] As shown in Figure 2, the inner wall (4) of the mask is evenly equipped with whirlwind blades (2), so that when the airflow enters the fire hole, a whirlwind effect is generated upward.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com