Electrospinning preparation method of silk fibroin/polyacrylonitrile-based antibacterial and anti-ultraviolet nanofiber membrane

A nanofiber membrane and electrospinning technology, which is applied in the direction of spinning solution preparation, fiber treatment, rayon manufacturing, etc., can solve the problems of unsustainable antibacterial effect, complicated process, troublesome operation, etc., to achieve good expansion space, antibacterial and antibacterial Bacteria effect is good, the effect of uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

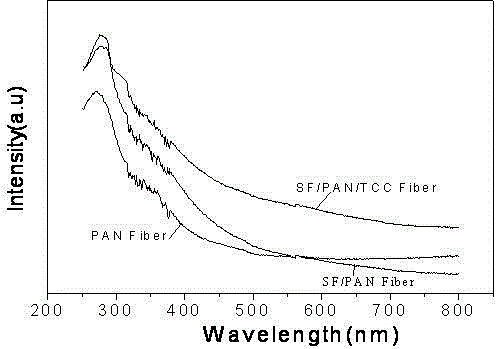

[0034] (1) Weigh SF and PAN powders with an electronic balance (the mass ratio of SF and PAN is 1:10, and the molar mass of PAN is Mw=170000 g / mol, and the mass fraction is 6%) and put them in a 20ml sample bottle, Use a pipette to pipette 15ml of N-N dimethylformamide (DMF), seal the sample bottle with raw tape, heat to 60°C and stir for 24 hours to finally obtain an electrospinning solution with uniform dispersion of SF and PAN.

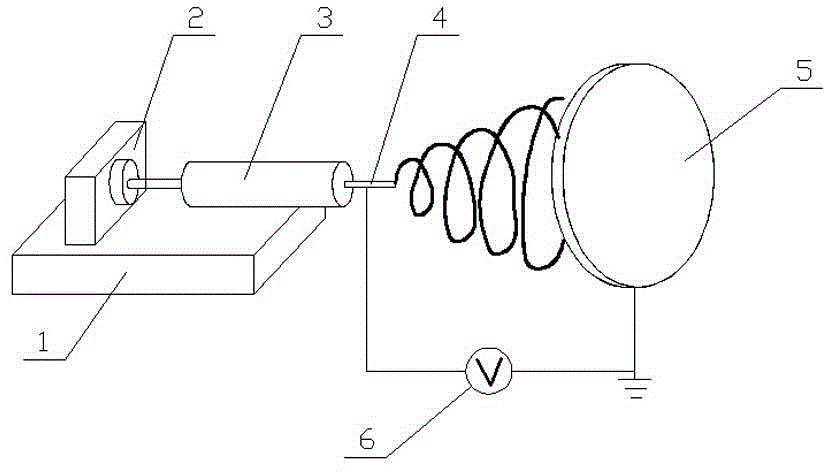

[0035] (2) adopt figure 1 The electrospinning device shown is for electrospinning, and the aluminum foil paper with an area of 40cm×40cm is cut out and attached to the receiving plate. Take 4ml of the spinning solution sample and put it into the injection needle (i.e., the syringe), and put the positive electrode of the high voltage generator Connect to the outlet of the spinneret 4, connect the negative electrode to the receiving plate, adjust the syringe pump to make the flow rate of the electrospinning solution 0.7ml / h, set the distance betwe...

Embodiment 2

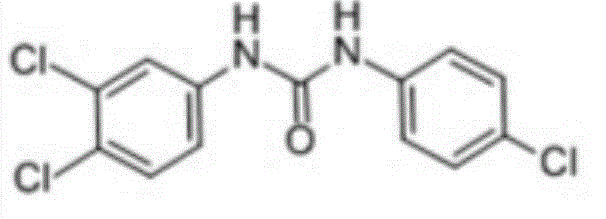

[0037] (1) Weigh the SF / PAN / TCC powder with an electronic balance (the mass ratio of the three is 10:10:3), in which the mass fraction of PAN (Mw=170000 g / mol) is 6%, and put it in a 20ml sample bottle , using a pipette to pipette 15ml of N-N dimethylformamide (DMF), the sample bottle is sealed with raw material tape, heated to 60 ° C and stirred for 24 hours, and finally the electrospun electrospun powder with relatively uniform dispersion of SF, PAN, and TCC is obtained. silk solution.

[0038](2) Cut out an aluminum foil paper with an area of 40cm×40cm and stick it on the receiving plate, take 4ml of the spinning solution sample and put it into the injection needle, connect the positive pole of the high voltage generator to the outlet of the spinneret, and connect the negative pole to the receiving plate , adjust the syringe pump so that the flow rate of the electrospinning solution is 0.7ml / h, set the distance between the spinneret and the receiving plate to 13cm, and th...

Embodiment 3

[0040] (1) Weigh SF / PAN / TCC powder with an electronic balance (the mass ratio of the three is 1:10:0.3), in which the mass fraction of PAN (Mw=130000 g / mol) is 8%, and put it in a 20ml sample bottle , using a pipette to pipette 15ml of N-N dimethylformamide (DMF), the sample bottle is sealed with raw material tape, heated to 60 ° C and stirred for 24 hours, and finally the electrospun electrospun powder with relatively uniform dispersion of SF, PAN, and TCC is obtained. silk solution.

[0041] (2) Cut out an aluminum foil paper with an area of 40cm×40cm and stick it on the receiving plate, take 4ml of the spinning solution sample and put it into the injection needle, connect the positive pole of the high voltage generator to the outlet of the spinneret, and connect the negative pole to the receiving plate , adjust the syringe pump so that the flow rate of the electrospinning solution is 0.7ml / h, set the distance between the spinneret and the receiving plate to 13cm, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molar mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com