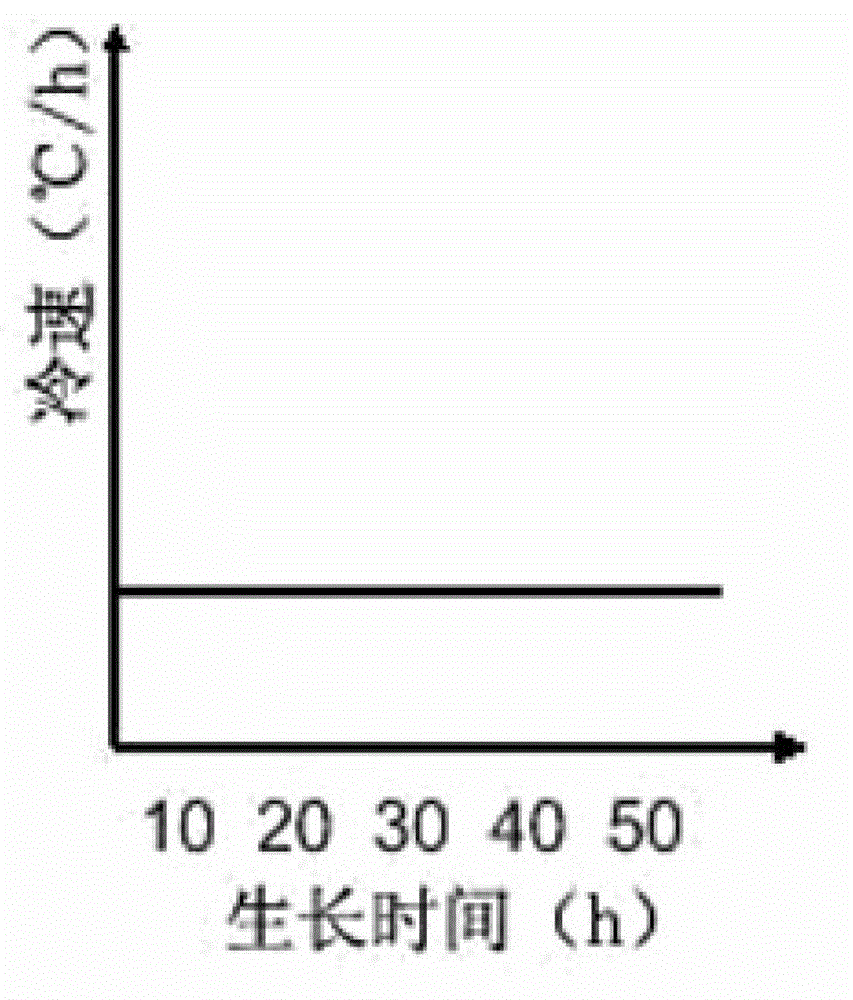

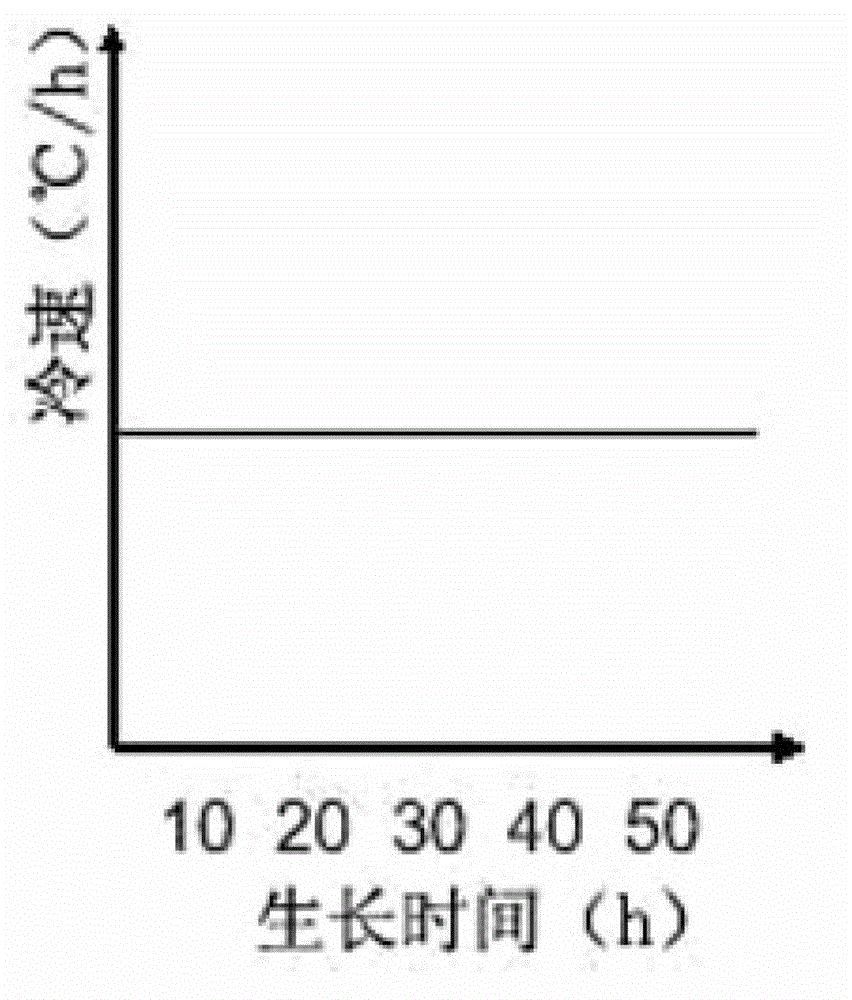

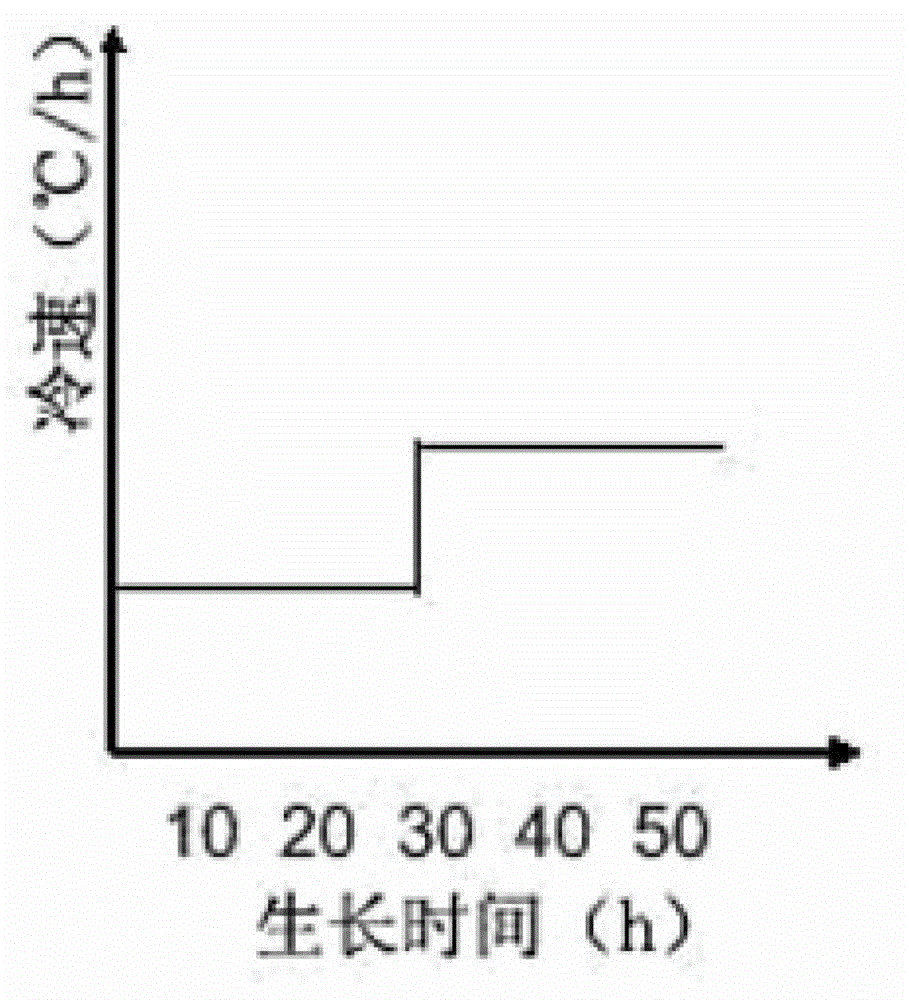

Method for quickly growing REBCO high-temperature superconducting block by stepped slow cooling acceleration

A technology for accelerated slow cooling and high-temperature superconductivity, applied in the directions of single crystal growth, crystal growth, single crystal growth, etc., can solve problems such as spontaneous nucleation, insufficient driving force, and slow growth rate, etc., with simple methods and shortened time , easy-to-operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1. According to the ratio of Sm:Ba:Cu=1:2:3 and Sm:Ba:Cu=2:1:1, Sm 2 o 3 、BaCO 3 Mix with CuO powder to obtain Sm123 phase and Sm211 phase powder, according to the ratio of Sm:Ba:Cu=2:4:2, Sm 2 o 3 、BaO 2 Mix with CuO powder to obtain Sm242 phase powder, according to the ratio of Sm: Ba: Cu: Bi = 2: 4: 1: 1, Sm 2 o 3 、BaCO 3 , CuO and Bi 2 o 3 The powders were mixed to obtain the Sm2411 phase powder.

[0034] 2. After fully grinding the Sm123 phase powder, Sm211 phase powder, Sm242 phase powder and Sm2411 phase powder obtained in step 1, respectively, put the Sm123 phase powder, Sm211 phase powder and Sm2411 phase powder in the air atmosphere In the process of sintering for 48h, the corresponding sintering temperatures are 900°C, 900°C and 950°C respectively; 2 In the atmosphere, sintering for 24h, the sintering temperature is 850 ℃. The sintered powder was ground and sintered again, and repeated three times to obtain Sm123 pure-phase powder, Sm211 pure-phase...

Embodiment 2

[0044] 1. According to the ratio of Sm:Ba:Cu=1:2:3 and Sm:Ba:Cu=2:1:1, Sm 2 o 3 、BaCO 3 Mix with CuO powder to obtain Sm123 phase and Sm211 phase powder, according to the ratio of Sm:Ba:Cu=2:4:2, Sm 2 o 3 、BaO 2 Mix with CuO powder to obtain Sm242 phase powder, according to the ratio of Sm: Ba: Cu: Bi = 2: 4: 1: 1, Sm 2 o 3 、BaCO 3 , CuO and Bi 2 o 3 The powders were mixed to obtain the Sm2411 phase powder.

[0045] 2. After fully grinding the Sm123 phase powder, Sm211 phase powder, Sm242 phase powder and Sm2411 phase powder obtained in step 1, respectively, put the Sm123 phase powder, Sm211 phase powder and Sm2411 phase powder in the air atmosphere In the process of sintering for 48h, the corresponding sintering temperatures are 900°C, 900°C and 950°C respectively; 2 In the atmosphere, sintering for 24h, the sintering temperature is 850 ℃. The sintered powder was ground and sintered again, and repeated three times to obtain Sm123 pure-phase powder, Sm211 pure-phase...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com