Method for preparing zno film with hierarchical structure porous array by electrodeposition method

A technology of hierarchical structure and electrodeposition method, applied in the direction of electrolytic inorganic material coating, etc., can solve the problem of high requirements for operators' basic skills and achieve the effect of reducing the technical difficulty of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

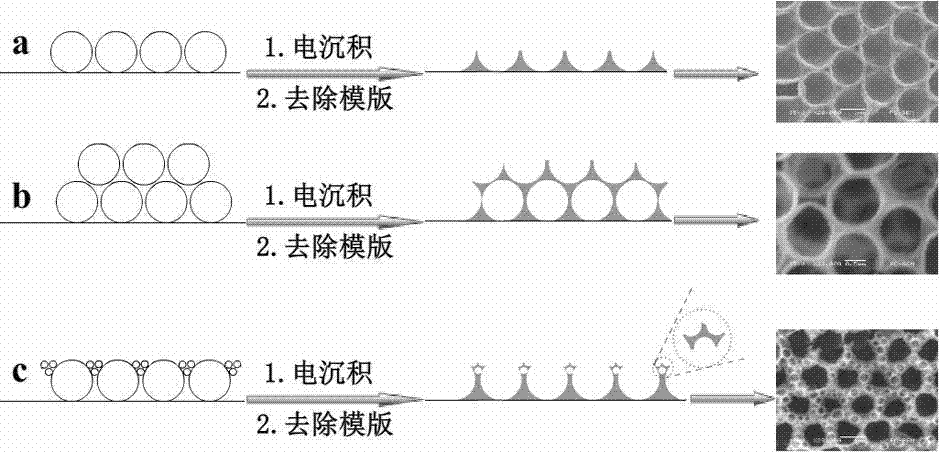

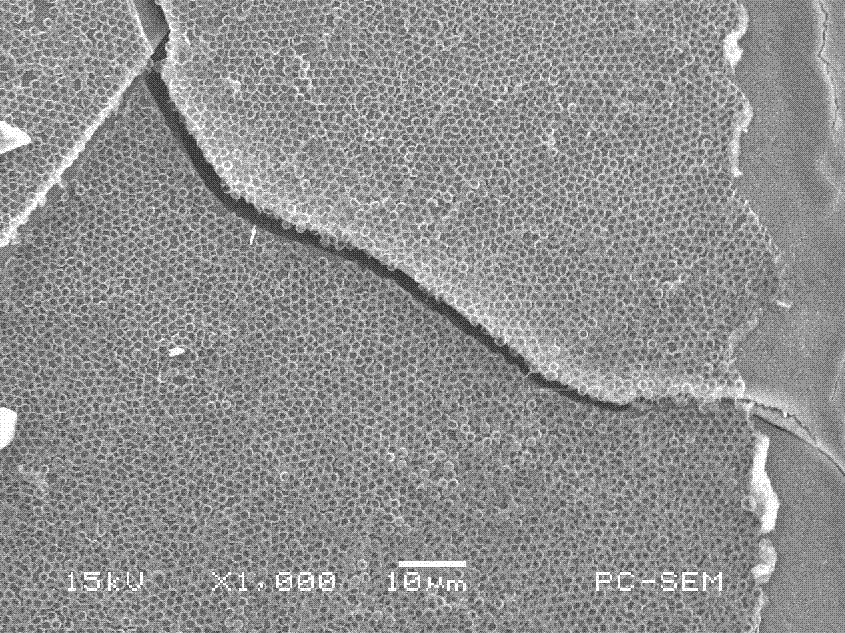

[0044] The method for preparing hierarchical structure porous array ZnO film by electrodeposition method comprises the following steps:

[0045]1) Assemble PS templates with different layers and particle sizes on the FTO conductive glass, the specific method is:

[0046] a. After cleaning the glass slide, vertically immerse it in a PS aqueous solution with a PS particle size of 2.5 μm (the PS mass concentration of the PS aqueous solution is 5%) and let it stand for 2 to 3 minutes, then pull it out vertically at a pulling speed of 4cm / min , dried at room temperature to obtain a single-layer array template, and then slowly insert the single-layer array template into water at an inclination angle of 45°, the PS beads are automatically peeled off and rearranged in a single layer on the water surface, and a single-layer array template floating on the water surface is obtained. layer PS template;

[0047] b. Use tweezers to take another FTO conductive glass (the size of FTO conduct...

Embodiment 2

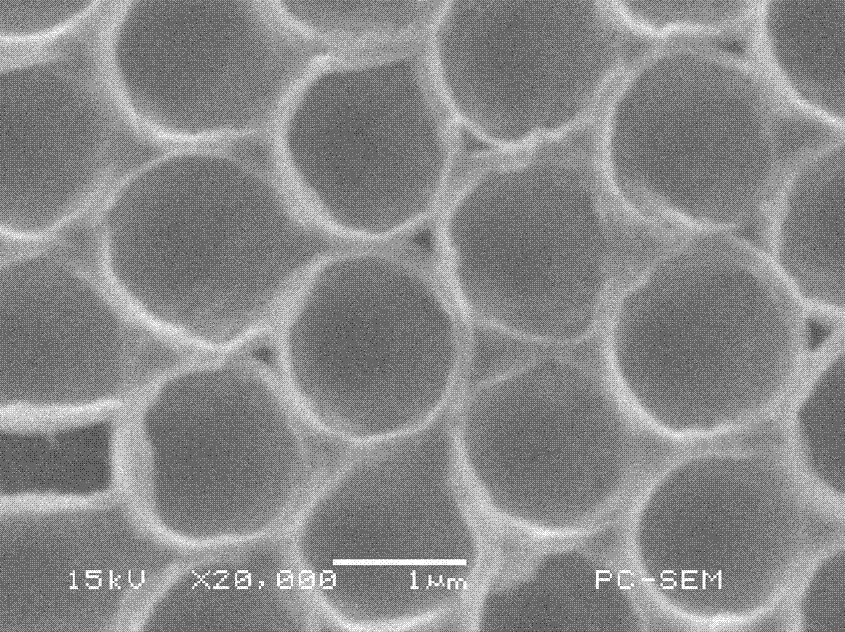

[0055] The method for preparing hierarchical structure porous array ZnO film by electrodeposition method comprises the following steps:

[0056] 1) Assemble PS templates with different layers and particle sizes on the FTO conductive glass, the specific method is:

[0057] a. After cleaning the glass slide, vertically immerse it in a PS aqueous solution with a PS particle size of 2.5 μm and let it stand for 2 to 3 minutes, then pull it out vertically at a pulling speed of 4 cm / min, and dry it at room temperature to obtain a single-layer array template. Then the single-layer array template is slowly inserted into the water at an inclination angle of 45°, the PS balls are automatically peeled off and rearranged in a single layer on the water surface, and a single-layer PS template floating on the water surface is obtained;

[0058] b. Use tweezers to take another FTO conductive glass (the size of FTO conductive glass is 2x1cm 2 ) as a carrier, after cleaning, insert the carrier ...

Embodiment 3

[0066] The method for preparing hierarchical structure porous array ZnO film by electrodeposition method comprises the following steps:

[0067] 1) Assemble PS templates with different layers and particle sizes on the FTO conductive glass, the specific method is:

[0068] a. After cleaning the glass slide, vertically immerse it in a PS aqueous solution with a PS particle size of 2.5 μm and let it stand for 2 to 3 minutes, then pull it out vertically at a pulling speed of 4 cm / min, and dry it at room temperature to obtain a single-layer array template. Then the single-layer array template is slowly inserted into the water at an inclination angle of 45°, the PS balls are automatically peeled off and rearranged in a single layer on the water surface, and a single-layer PS template floating on the water surface is obtained;

[0069] b. Use tweezers to take another FTO conductive glass (the size of FTO conductive glass is 2x1cm 2 ) as a carrier, after cleaning, insert the carrier ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com