Preparation method of copper/modal fiber composite material

A modal fiber and composite material technology is applied in the field of preparation of copper/modal fiber composite materials, which can solve the problems of heavy wearability, high copper fiber density and high cost, and achieve the effect of reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

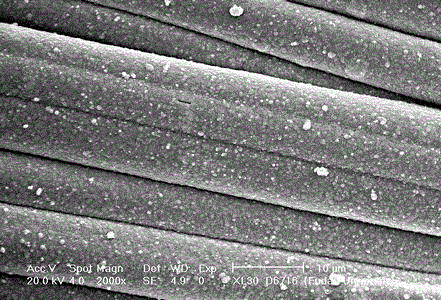

Image

Examples

Embodiment 1

[0019] Wash the modal fiber cloth with a weight of 1.3g and an area of 10cm×10cm with deionized water, dry it, place it in an aqueous solution of citric acid with a concentration of 10%, soak it for 24 hours, take it out, and bake it at 100°C for 3 hours, cooling, washing, and drying to obtain surface-modified modal fibers.

[0020] Put the modified modal fiber in a copper sulfate aqueous solution with a concentration of 50g / L for 12 hours, take it out, wash it, put it in a sodium borohydride aqueous solution with a temperature of 0°C and a concentration of 0.1g / L for 10 minutes, take it out, Wash to obtain surface-activated modal fibers.

[0021] Dissolve 5g of copper sulfate, 8g of sodium potassium tartrate, 5g of ethylenediaminetetraacetic acid disodium salt, 1g of dimethylaminoborane, and 0.1g of polyethylene glycol (relative molecular weight 4000) in 500mL of deionized water. After the dissolution is complete, add deionized water until the volume of the solution is 1 L...

Embodiment 2

[0024] Wash the modal fiber cloth with a weight of 1.3g and an area of 10cm×10cm with deionized water, dry it, place it in an aqueous solution of malic acid with a concentration of 25%, soak it for 12 hours, take it out, and bake it at 120°C for 3 hours, cooling, washing, and drying to obtain surface-modified modal fibers.

[0025] Put the modified modal fiber in a copper sulfate aqueous solution with a concentration of 100g / L for 3 hours, take it out, wash it, put it in a sodium borohydride aqueous solution with a temperature of 5°C and a concentration of 0.3g / L for 5 minutes, take it out, Wash to obtain surface-activated modal fibers.

[0026] Dissolve 8g of copper sulfate, 10g of sodium potassium tartrate, 8g of ethylenediaminetetraacetic acid disodium salt, 1.5g of dimethylaminoborane, and 0.2g of polyethylene glycol (relative molecular weight 4000) in 500mL of deionized water. Add deionized water until the volume of the solution is 1 L to obtain a copper electroless pl...

Embodiment 3

[0029] Wash the modal fiber cloth with a weight of 1.3g and an area of 10cm×10cm with deionized water, dry it, place it in a methanol solution of tartaric acid with a concentration of 15%, soak it for 18 hours, take it out, and bake it at 100°C for 3 hours, cooling, washing, and drying to obtain surface-modified modal fibers.

[0030] Put the modified modal fiber in an aqueous copper sulfate solution with a concentration of 80g / L for 6 hours, take it out, wash it, put it in an aqueous solution of sodium borohydride at a temperature of 3°C and a concentration of 0.2g / L for 8 minutes, take it out, Wash to obtain surface-activated modal fibers.

[0031] Dissolve 6g of copper sulfate, 9g of sodium potassium tartrate, 6g of ethylenediaminetetraacetic acid disodium salt, 1.2g of dimethylaminoborane, and 0.15g of polyethylene glycol (relative molecular weight 4000) in 500mL of deionized water. Add deionized water until the volume of the solution is 1 L to obtain a copper electrole...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com