Polyurethane/polyacrylate copolymer and BOPP (Biaxially-oriented Polypropylene) film prepared by same

A technology of polyacrylate and hydroxy acrylate, applied in coating and other directions, can solve the problems of insufficient film performance, short service life, poor coating performance, etc., and achieve a simple and rapid film forming process and good dimensional stability. , the effect of excellent elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

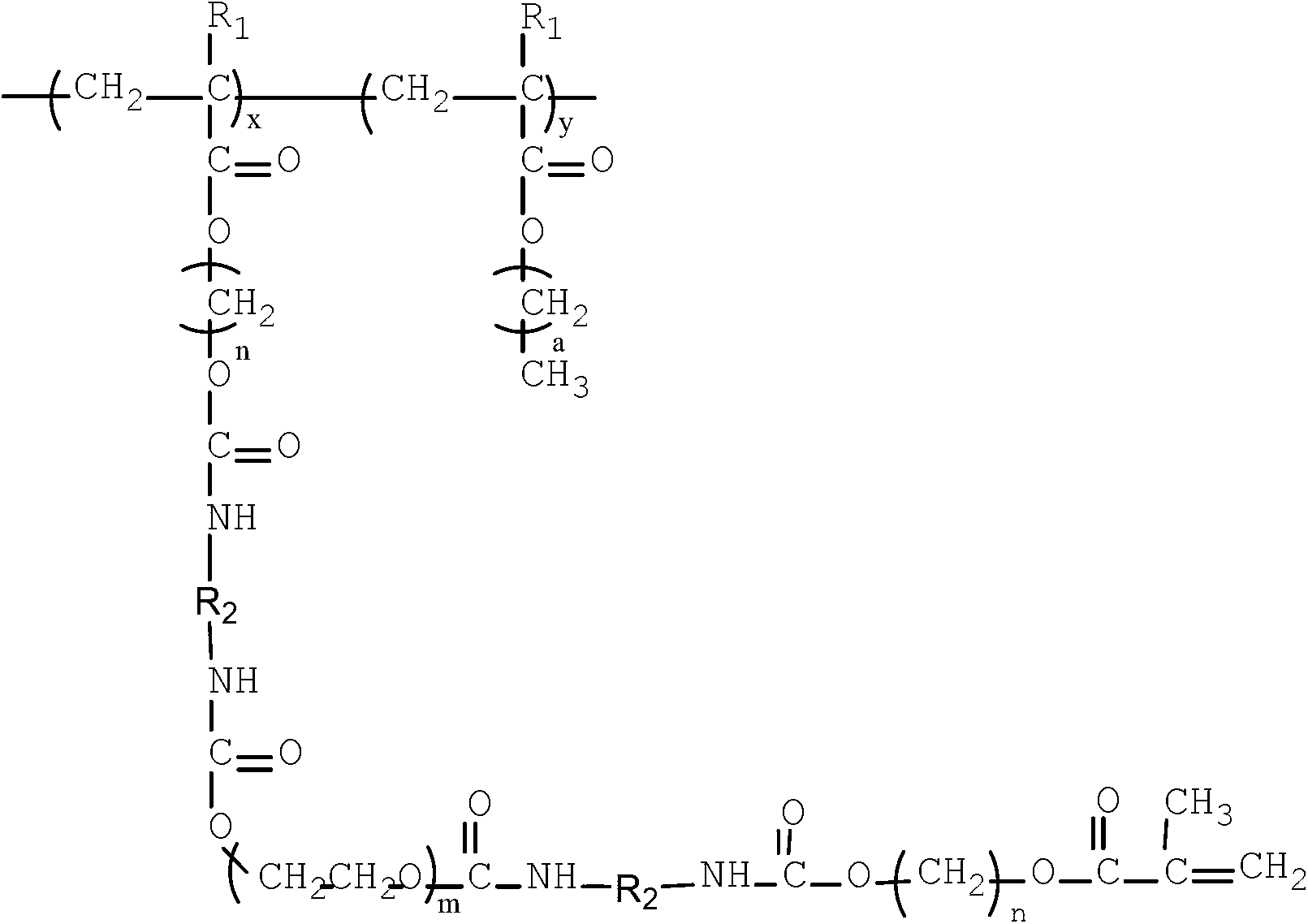

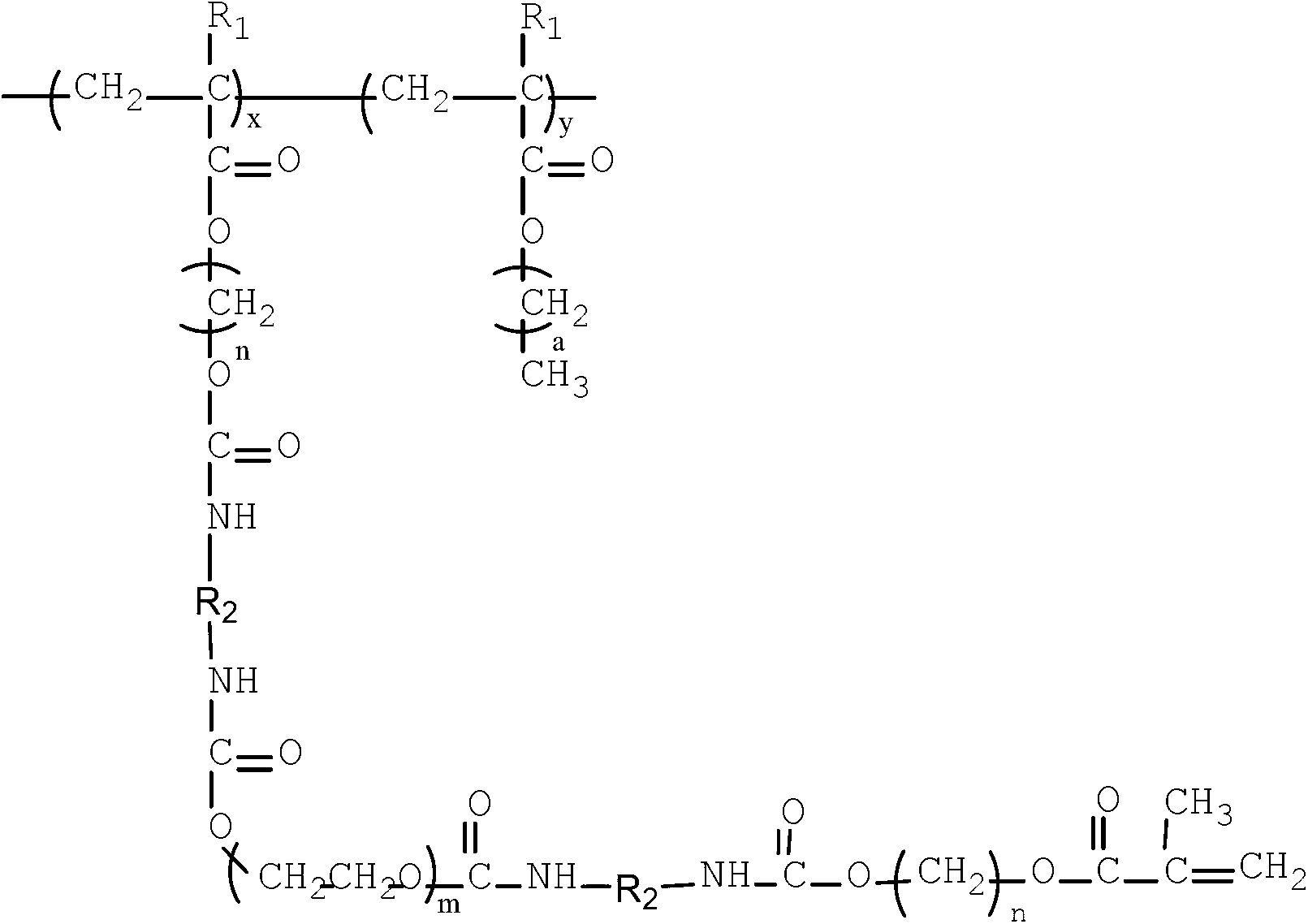

Image

Examples

Embodiment 1

[0030] (1) Preparation of polyurethane macromonomer terminated with hydroxyethyl methacrylate: dehydrate polyether diol by rotary evaporation, and vacuum dry it in a vacuum oven at 120°C to obtain dehydrated polyether diol . According to the weight ratio, add 100 parts of dehydrated polyether diol N210 (molecular weight: 1000) into a reactor equipped with a stirrer and a thermometer, raise the temperature to 80°C, and then add 34 parts of toluene diisocyanate, under the condition of stirring Mix evenly at 80°C and continue to react for 3 hours to obtain a polyurethane prepolymer with an end group of -NCO-; then add 26 parts of hydroxyethyl methacrylate to block the -NCO-, and react at 80°C for 4 Hours later, the sample was taken for testing, and the results of its infrared spectrum showed that at 3335cm -1 The -NH- stretching vibration peak appeared at 1730cm -1 The carbonyl stretching vibration peak appeared at , indicating that the isocyanate group of toluene diisocyanate ...

Embodiment 2

[0036] (1) Preparation of polyurethane macromonomer terminated with hydroxyethyl methacrylate: dehydrate polyether diol by rotary evaporation, and vacuum dry it in a vacuum oven at 120°C to obtain dehydrated polyether diol . According to the weight ratio, add 100 parts of dehydrated polyether diol N210 (molecular weight: 1000) into a reactor equipped with a stirrer and a thermometer, raise the temperature to 70°C, and then add 50 parts of diphenylmethane diisocyanate, Mix well under the condition of stirring, and continue to react for 3 hours to obtain a polyurethane prepolymer whose terminal group is -NCO-; then add 26 parts of hydroxyethyl methacrylate to block -NCO-, and react at 80°C After 4 hours, the sample was taken for testing, and the results of its infrared spectrum showed that at 3335cm -1 The -NH- stretching vibration peak appeared at 1730cm -1 The carbonyl stretching vibration peak appeared at , indicating that the isocyanate group of diphenylmethane diisocyanat...

Embodiment 3

[0042] (1) Preparation of polyurethane macromonomer terminated with hydroxyethyl methacrylate: dehydrate polyether diol by rotary evaporation, and vacuum dry it in a vacuum oven at 120°C to obtain dehydrated polyether diol . According to the weight ratio, add 100 parts of dehydrated polyether diol N210 (molecular weight: 1000) into a reactor equipped with a stirrer and a thermometer, raise the temperature to 85 ° C, and then add 44 parts of isophorone diisocyanate, in Mix well under stirring conditions, and continue to react for 7 hours to obtain a polyurethane polymer whose end group is -NCO-; then add 26 parts of hydroxyethyl methacrylate to end-cap the -NCO-, and react at 80°C for 3 Hours later, the sample was taken for testing, and the results of its infrared spectrum showed that at 3335cm -1 The -NH- stretching vibration peak appeared at 1730cm -1 The carbonyl stretching vibration peak appeared at , indicating that the isocyanate group of isophorone diisocyanate reacted...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface tension | aaaaa | aaaaa |

| Flexibility | aaaaa | aaaaa |

| Surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com