Epoxy modified water-soluble acrylic resin, and preparation method and application thereof

A water-soluble acrylic and epoxy modification technology, applied in coatings and other directions, can solve the problems of chemical resistance and poor adhesion, and achieve the effect of good gloss, excellent comprehensive performance and good chemical performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

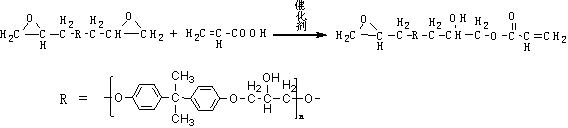

Method used

Image

Examples

Embodiment 1

[0033] Preparation of unsaturated double bond-terminated epoxy resin: In the reaction kettle, add 60 parts of E-44 epoxy resin and 13 parts of n-butanol in advance, heat to 70 °C and stir evenly, then heat up to 120 °C; In the cylinder, 0.3 parts of N,N-dimethylethanolamine; 15 parts of methacrylic acid; 10 parts of n-butanol, after stirring evenly, drop them into the reaction kettle within 1 hour, and continue to keep warm for 1 hour at 100°C , stop the reaction when the acid value of the system basically does not change, and cool down to room temperature, that is, the unsaturated double bond-terminated epoxy resin is prepared.

[0034] In another reactor, add 30 parts of diethylene glycol monobutyl ether; 1.2 parts of methyl methacrylate; 2.9 parts of butyl acrylate; 0.3 parts of methacrylic acid; 0.39 parts of hydroxyethyl acrylate; 0.1 parts of mercaptoethanol ; 0.2 parts of benzoyl peroxide, heated to 85 ° C for 15 minutes.

[0035]In the dripping tank, add 20 parts of d...

Embodiment 2

[0037] Preparation of unsaturated double bond-terminated epoxy resin: In the reaction kettle, add 65 parts of E-51 epoxy resin and 10 parts of diethylene glycol monobutyl ether in advance, heat to 65 °C and stir evenly, then heat up to 100 °C ; In the drop tank, 0.4 parts of tetrabutylammonium bromide; 10 parts of methacrylic acid; Continue the heat preservation reaction for 1.5 hours, stop the reaction when the acid value of the system does not change substantially, and cool down to room temperature to obtain an unsaturated double bond-terminated epoxy resin.

[0038] In the reactor, add 35 parts of diethylene glycol monobutyl ether in advance; 2 parts of methyl methacrylate; 3.9 parts of butyl acrylate; 0.5 parts of methacrylic acid; 0.45 parts of hydroxyethyl acrylate; 0.08 part of benzoyl oxide was heated to 85°C for 15 minutes to react.

[0039] In the dripping tank, add 15 parts of diethylene glycol monobutyl ether; 18 parts of methyl methacrylate; 14.1 parts of butyl a...

Embodiment 3

[0041] Preparation of unsaturated double bond-terminated epoxy resin: In the reaction kettle, add 70 parts of E-44 epoxy resin and 15 parts of propylene glycol monobutyl ether in advance, heat to 60 °C and stir evenly, then heat up to 110 °C; In the tank, add 0.5 parts of triethylamine; 12 parts of acrylic acid; 15 parts of propylene glycol monobutyl ether. After stirring evenly, drop them into the reaction kettle within 3 hours, and continue to keep warm for 2 hours at 120°C. When there is basically no change, the reaction is stopped and the temperature is lowered to room temperature to obtain an unsaturated double bond-terminated epoxy resin.

[0042] In the reactor, add 30 parts of diethylene glycol monobutyl ether in advance; 1.2 parts of methyl methacrylate; 2.9 parts of butyl acrylate; 0.3 parts of methacrylic acid; 0.27 parts of hydroxyethyl acrylate; 0.1 part of benzoyl oxide was heated up to 85°C for 15 minutes.

[0043] In the dripping tank, add 15 parts of diethyle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com