Suspension filler for water treatment

A suspension filler and water treatment technology, applied in the field of water treatment, can solve the problems of high density, discomfort, poor mechanical properties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

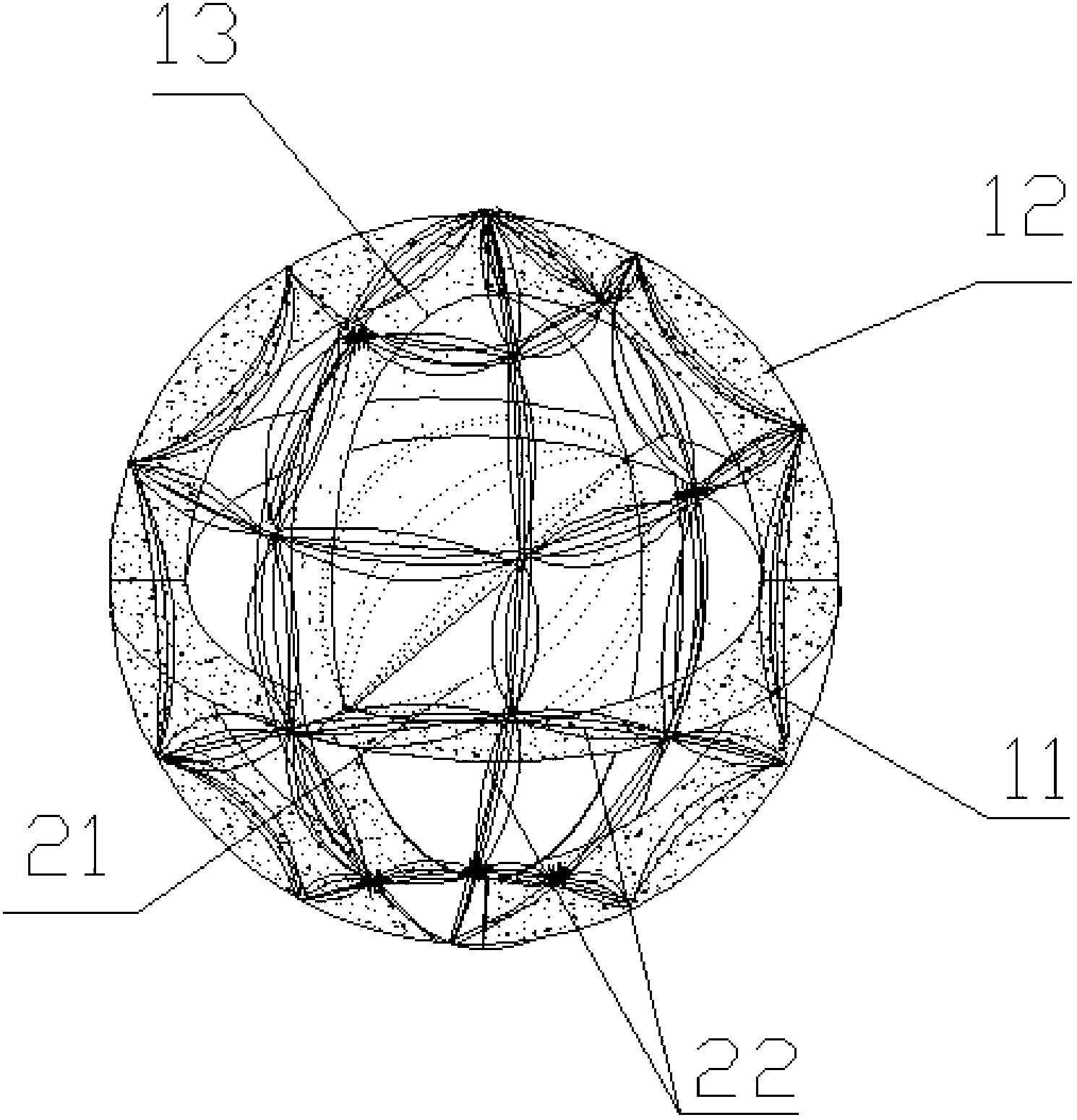

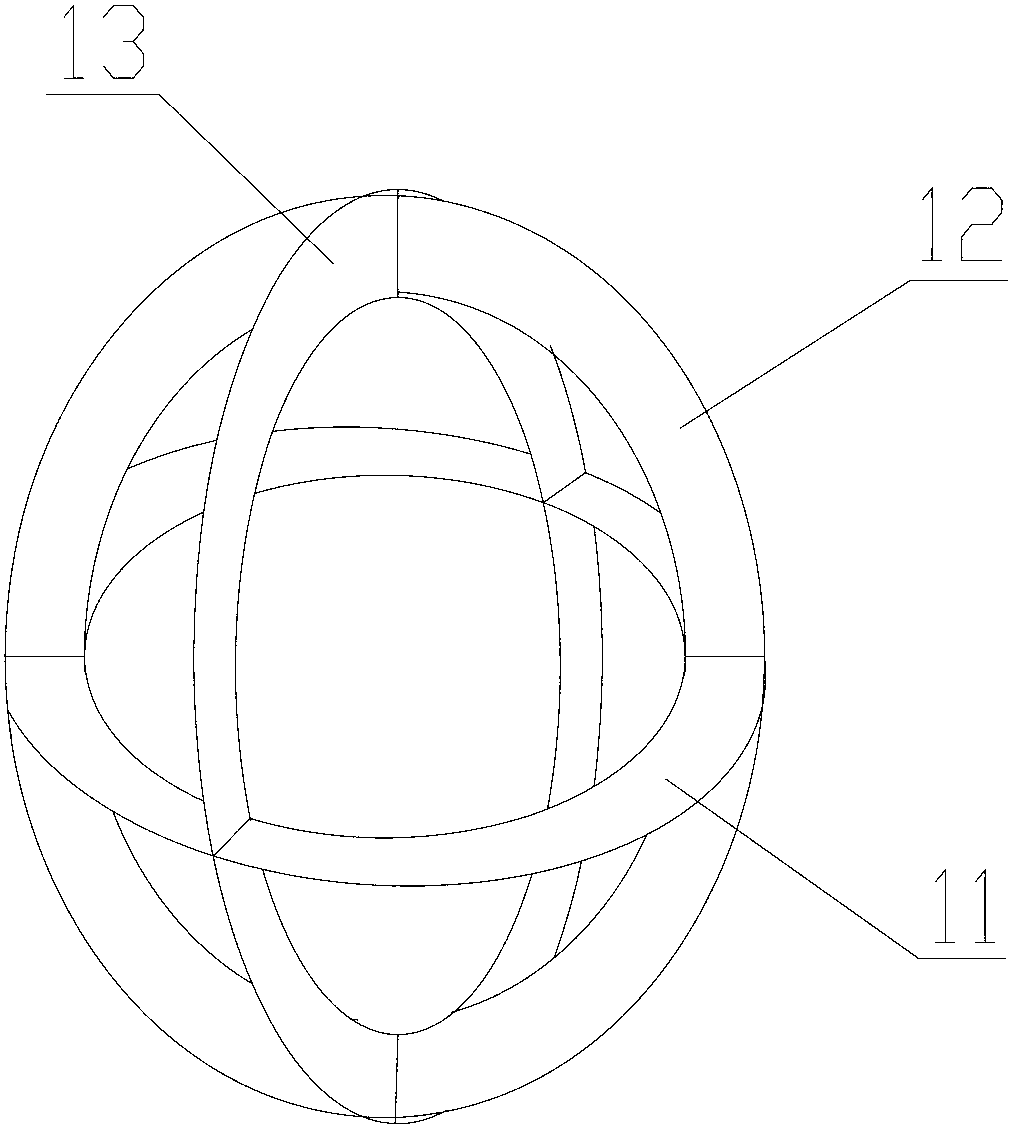

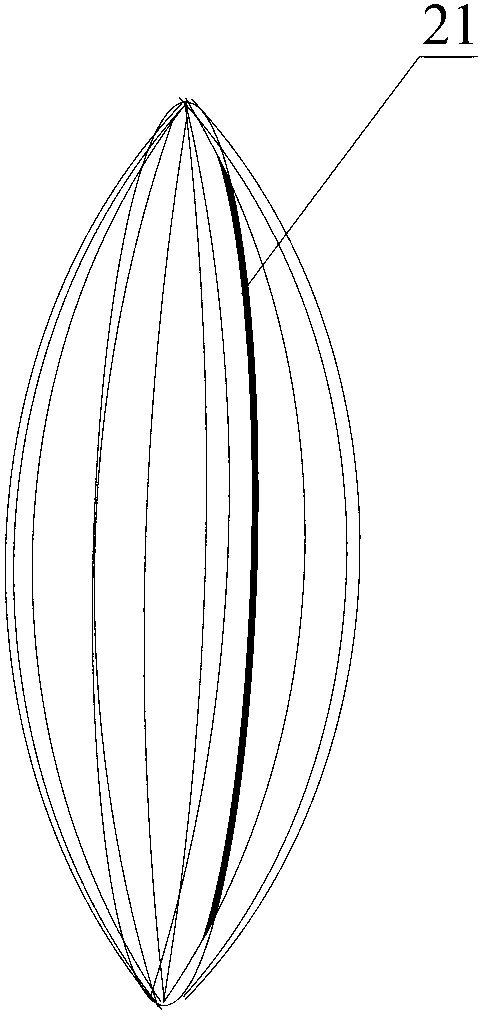

[0044] The specific surface area is 1000m 2 / g, polyacrylonitrile-based carbon fiber bundles with a diameter of 7 μm are cut into small carbon fiber bundles with a length of about 5cm, 6cm, and 7cm (a bundle of about 1000 fiber filaments), and the three bundles of carbon fiber bundles are fixed by a binder On a first ring frame 11 with a diameter of 5 cm. Then, the carbon fiber bundle with a length of 50 cm is wound on the first ring frame 11 and the second ring frame 12, and is combined and fixed into a net packing with a string. Put 30 water treatment suspension fillers 30 (about 150 g) prepared in the above-mentioned manner according to the embodiment of the present invention into a 5 L glass reactor 31 , and the filler filling rate is about 60%.

[0045] Take river water as the treatment object, place the water treatment suspension packing 30 in the glass reactor 31, aerate the water treatment suspension packing 30 through the air inlet on the glass reactor 31, and keep t...

Embodiment 2

[0050] The water treatment suspension filler 30 prepared above and the biological fluidized bed have the same reaction conditions, and the treatment object is the bleaching wastewater of the pulp mill, and its wastewater is chlorine-containing toxic wastewater. ~25°C.

Embodiment 3

[0055] With the biological fluidized bed used in Example 1, the equipment conditions are consistent, and the treatment object is the flotation wastewater of the mineral processing plant, and its wastewater contains Pb 2+ 0.02~0.42mg / L, Zn 2+ 0.02~1.27mg / L, As + 0.05~0.16mg / L, Cu 2+ 0.02~0.30mg / L, total chromium 0.05~0.44mg / L, COD Cr 120~285mg / L, add a small amount of activated sludge domesticated by the wastewater, and the reaction temperature is 18~25°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com