Cutting method of frangible super thin sheet or film material

A technology of thin film materials and cutting methods, which is applied in metal processing and other directions, can solve the problems of adsorption pipeline blockage, material damage, and the inability to ensure that all cut samples are fixed, and achieve the effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

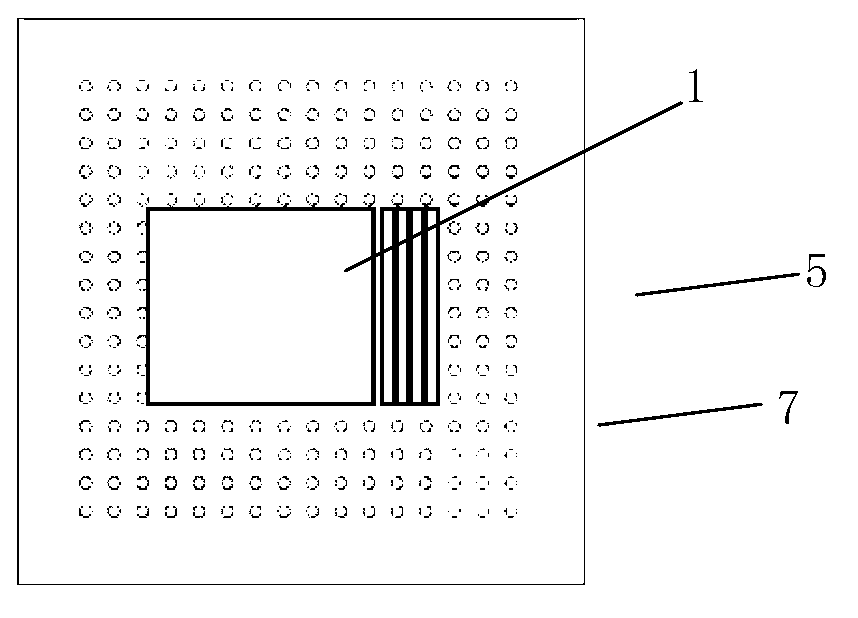

[0035] a. On the adsorption surface workbench 2 with adsorption holes 6, lay a breathable silicon wafer 5 with holes 7 of 0.5 μm, a spacing of 5 μm, and a thickness of 30 μm. The adsorption holes 6 on the adsorption surface workbench 2 and the vacuum pump 3 To connect, the fragile ultra-thin ceramic sheet 1 is placed on the gas-permeable silicon sheet 5;

[0036] b. Turn on the vacuum pump 3, through the hole 6 on the adsorption surface workbench 2 and the hole 7 on the air-permeable silicon wafer 5, the fragile ultra-thin ceramic sheet 1 is tightly adsorbed on the surface of the air-permeable silicon wafer 5, on the adsorption surface workbench 2 The negative pressure between the gas-permeable silicon wafer 5 is -50kpa, making the gas-permeable silicon wafer 5 a secondary adsorption table during work;

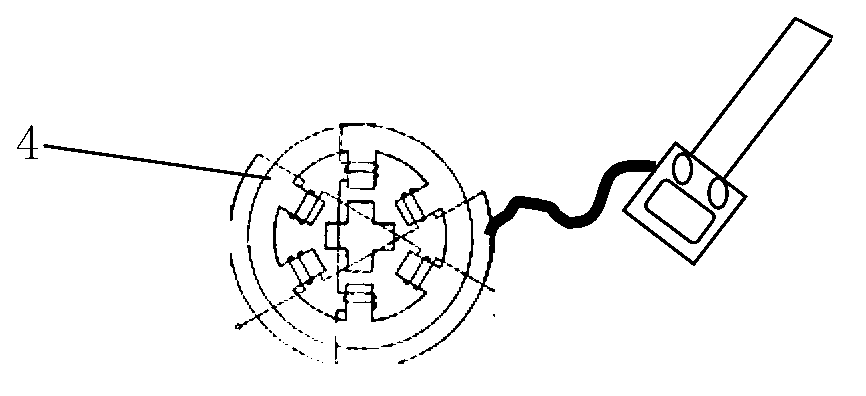

[0037] c. Connect the stepping motor 4 with a mechanical cutter, control the stepping motor 4 with a computer program, and use a mechanical cutter with a blade of 10nm to cut ...

Embodiment 2

[0041] a. On the adsorption surface workbench 2 with adsorption holes 6, lay a breathable silicon wafer 5 with holes 7 of 1.0 μm, a spacing of 8 μm, and a thickness of 50 μm. The adsorption holes 6 on the adsorption surface workbench 2 and the vacuum pump 3 To connect, the fragile ceramic film 1 is placed on the gas-permeable silicon wafer 5;

[0042]b. Turn on the vacuum pump 3, and through the holes 6 on the adsorption surface workbench 2 and the holes 7 on the air-permeable silicon wafer 5, the fragile ceramic film 1 is tightly adsorbed on the surface of the air-permeable silicon wafer 5. The negative pressure between the silicon wafers 5 is -40kpa, making the air-permeable silicon wafer 5 a secondary adsorption platform during work;

[0043] c. Connect the stepping motor 4 with a mechanical cutter, use a computer program to control the stepping motor 4, and use a mechanical cutter with a blade of 30 nm to cut the fragile ceramic film. After cutting once, follow the predete...

Embodiment 3

[0047] a. On the adsorption surface workbench 2 with adsorption holes 6, lay a breathable silicon wafer 5 with holes 7 of 5.0 μm, a spacing of 10 μm, and a thickness of 80 μm. The adsorption holes 6 on the adsorption surface workbench 2 and the vacuum pump 3 Connecting, placing the fragile ultra-thin chip 1 on the air-permeable silicon chip 5;

[0048] b, turn on the vacuum pump 3, through the hole 6 on the adsorption surface workbench 2 and the hole 7 on the air-permeable silicon wafer 5, the fragile ultra-thin chip 1 is tightly adsorbed on the surface of the air-permeable silicon wafer 5, between the adsorption surface workbench 2 and the air-permeable silicon wafer 5 The negative pressure between the breathable silicon wafers 5 is -30kpa, making the breathable silicon wafers 5 a secondary adsorption platform during work;

[0049] c. Connect the stepper motor 4 with a sharp metal wire, control the stepper motor 4 with a computer program, and cut the fragile ceramic chip with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com