Sudan red I molecularly-imprinted solid phase extraction padding, solid phase extraction column as well as preparation method and application of padding

A solid-phase extraction column and molecular imprinting technology, which can be used in the analysis of materials, chemical instruments and methods, and material separation, and can solve the problem of low separation selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

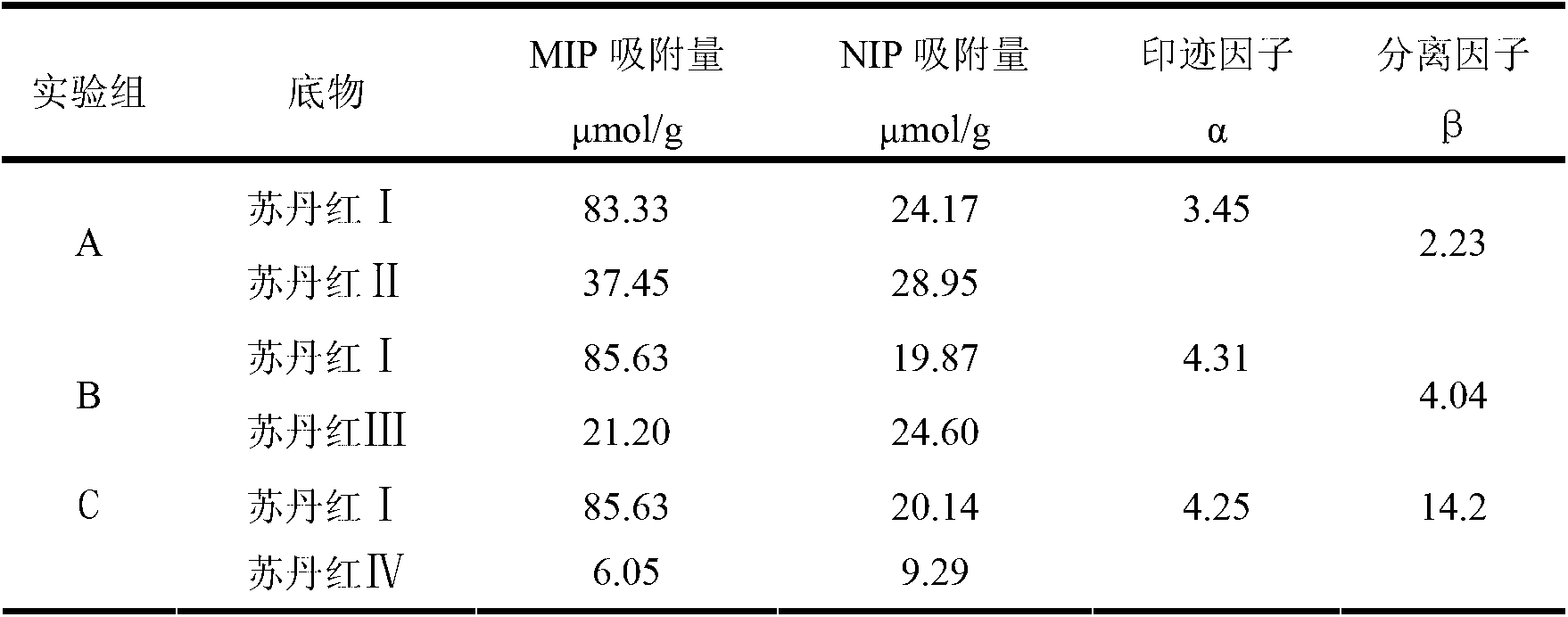

Image

Examples

Embodiment 1

[0027] 1. Preparation of Sudan Red Ⅰ Molecularly Imprinted SPE Cartridge

[0028] (1) Preparation of Molecularly Imprinted Polymer Microparticles Containing Sudan I

[0029] Weigh 0.2mmol of Sudan Red I and 4mmol of acrylamide, dissolve them in 3mL of ethyl acetate, place them in the dark for 2h, add 2mmol of maleic rosin ethylene glycol acrylate, 0.3g of azobisisobutyronitrile, 3mL of soybean oil, and 10mL of acetic acid Ethyl ester, ultrasonically dissolved to form a uniform organic phase solution A; solution B is an aqueous solution of sodium lauryl sulfate with a mass concentration of 0.15%; take 145 mL of solution B and place it in a three-necked flask, and install a stirrer and a water separator (note Filled with distilled water), condenser and thermometer, transfer solution A into solution B under stirring, stir at a constant speed (250r / min) at room temperature for 20min; heat to make the reaction system warm up slowly to 75-78°C, and react for 1h; Discard the solutio...

Embodiment 2

[0040] 1. Preparation of Sudan Red Ⅰ Molecularly Imprinted SPE Cartridge

[0041] (1) Preparation of Molecularly Imprinted Polymer Microparticles Containing Sudan I

[0042] Weigh 0.4mmol Sudan Red Ⅰ, 8mmol acrylamide, dissolve in 6mL ethyl acetate, place in the dark for 2h, add 4mmol maleic rosin glycol acrylate, 0.6g azobisisobutyronitrile, 6mL soybean oil, 20mL acetic acid Ethyl ester, ultrasonically dissolved to form a uniform organic phase solution A; solution B is an aqueous solution of sodium lauryl sulfate with a mass concentration of 0.15%; take 300 mL of solution B and place it in a three-necked flask, and install a stirrer and a water separator (note Filled with distilled water), condenser and thermometer, transfer solution A into solution B under stirring, stir at a constant speed (250r / min) at room temperature for 20min; heat to make the reaction system warm up slowly to 75-78°C, and react for 1h; Discard the solution in the water separator, slowly raise the temp...

Embodiment 3

[0053] 1. Preparation of Sudan Red Ⅰ Molecularly Imprinted SPE Cartridge

[0054] (1) Preparation of Molecularly Imprinted Polymer Microparticles Containing Sudan I

[0055] Weigh 0.6mmol of Sudan Red I and 12mmol of acrylamide, dissolve them in 10mL of ethyl acetate, place them in the dark for 12h, add 6mmol of maleic rosin ethylene glycol acrylate, 0.9g of azobisisobutyronitrile, 10mL of soybean oil, and 30mL of acetic acid Ethyl ester is dissolved by ultrasonic to form a uniform organic phase solution A; solution B is an aqueous solution of sodium lauryl sulfate with a mass concentration of 0.15%; take 450 mL of solution B and place it in a three-necked flask, and install a stirrer and a water separator (note Filled with distilled water), condenser and thermometer, transfer solution A into solution B under stirring, stir at a constant speed (250r / min) at room temperature for 20min; heat to make the reaction system warm up slowly to 75-78°C, and react for 1h; Discard the so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com