DC motor speed control circuit based on bridge servo control

A DC motor and servo control technology, applied in the direction of excitation or armature current control, etc., can solve the problems of circuit board temperature rise, affecting the accuracy of circuit work, product stability, etc., to achieve the effect of improving stability and reducing the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

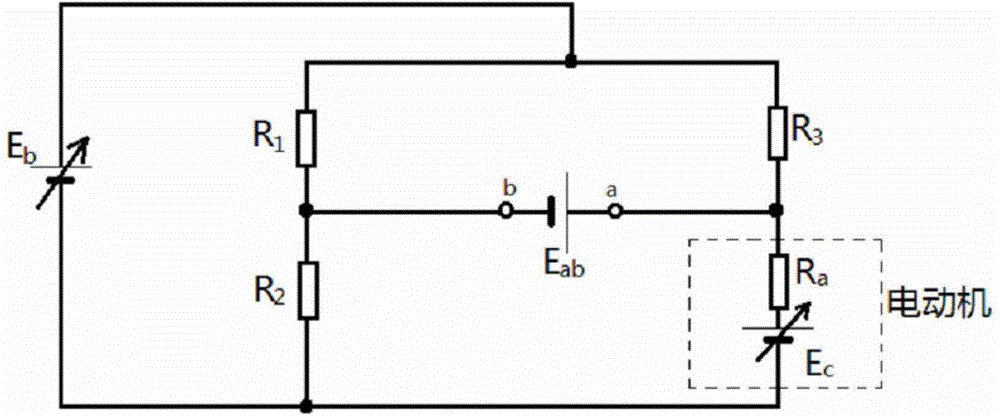

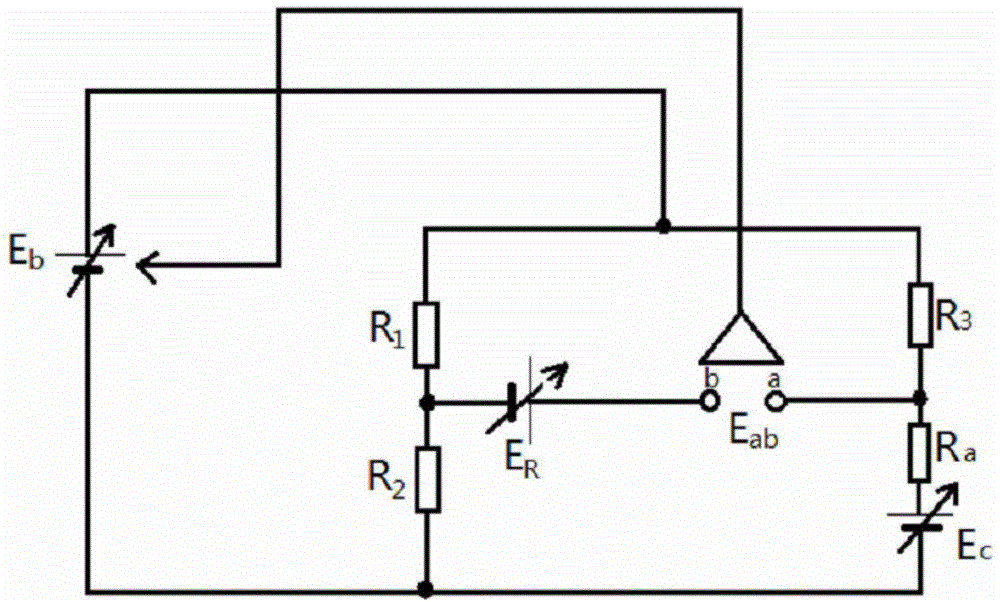

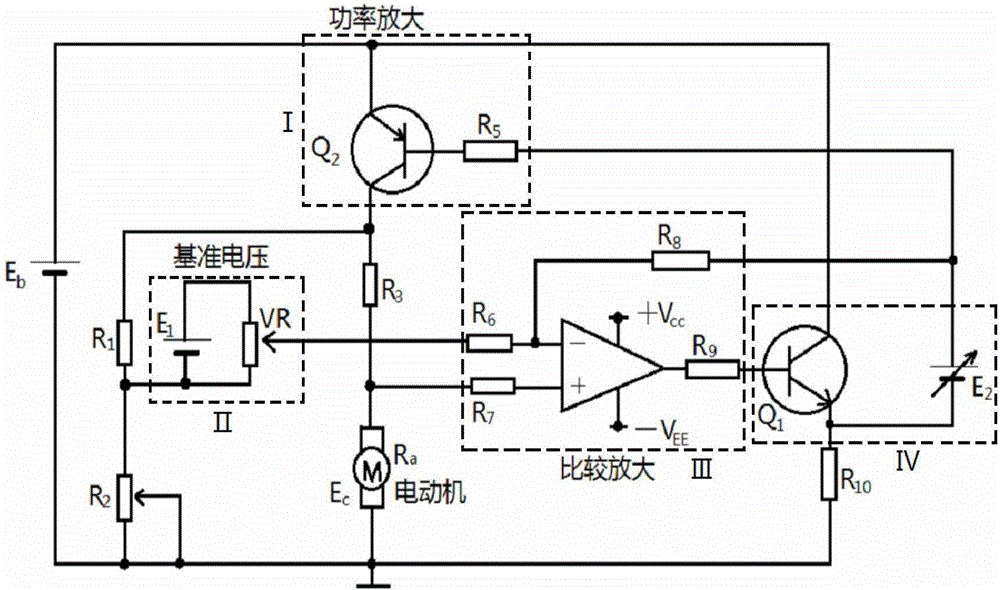

[0013] A practical DC motor can be used including the armature resistance R a and back EMF source E c represented by an equivalent circuit. Therefore, a bridge circuit including a motor such as figure 1 shown. When the bridge circuit is formed, the parameter value of the bridge arm resistance should meet the following proportional conditions, that is, R 1 :R 2 =R 3 :R a , so as to ensure that when the motor speed is zero, the output voltage E of the bridge circuit ab Also zero. When the motor rotates, the motor will induce a back electromotive force E that is proportional to the rotational speed c , the output voltage of the bridge circuit E ab will also be related to the back EMF E c (that is, proportional to the motor speed). In this way, it is possible to use the E ab As a speed signal, the speed of the motor is controlled.

[0014] When the load of the motor changes, in order to keep the speed of the motor constant, as long as the output voltage E of the bridg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com