A rewiring high-density AAQFN packaging device and its manufacturing method

A technology for packaging devices and manufacturing methods, applied in semiconductor/solid-state device manufacturing, electrical solid-state devices, semiconductor devices, etc., can solve problems affecting the yield and reliability of packaging devices, collapse of metal wires, and increase in manufacturing costs, and achieve improved Yield and reliability, low cost, effectiveness in resolving slumps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention is described in detail below in conjunction with accompanying drawing:

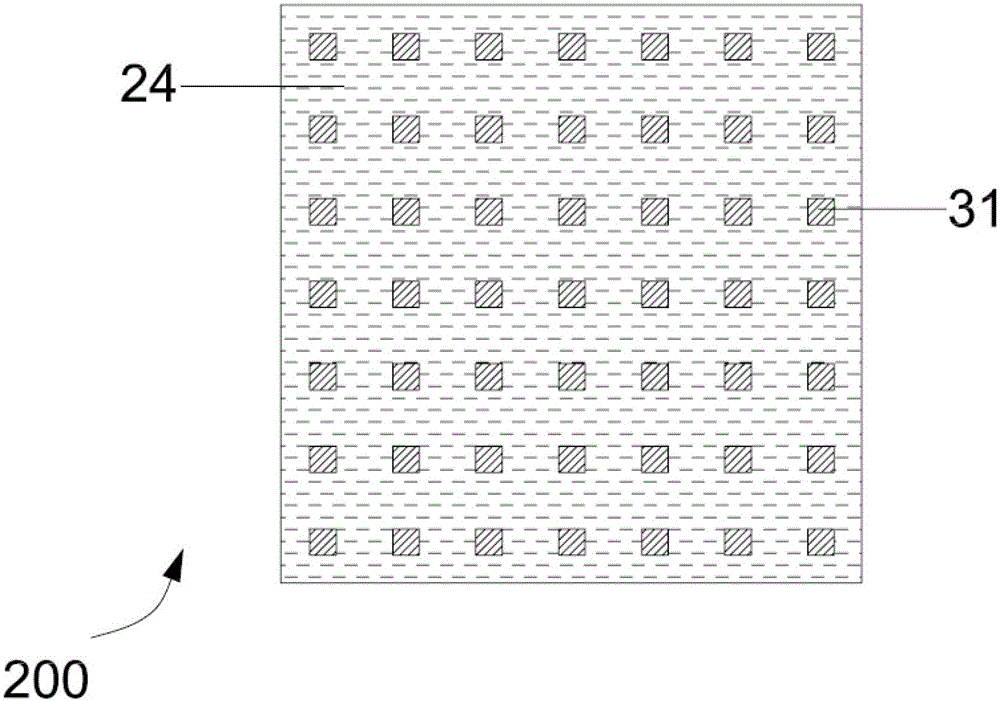

[0044] Figure 2A A schematic diagram of the rear side of a rewiring high-density AAQFN packaged device in which the cross-section of the pins is rectangular and the pins are arranged in parallel according to an embodiment of the present invention.

[0045] Refer to the above Figure 2A It can be seen that, in this embodiment, the second metal material layer 31 is disposed on the surface of the pins 22 arranged in an area array in the rewiring high-density AAQFN package device 200, the pins 22 are arranged in parallel, and the pins 22 The cross-section is rectangular, and the insulating filling material 24 is disposed in the rewiring high-density AAQFN package device 200 . In this embodiment, the arrangement of the pins 22 is not limited to a parallel arrangement, but may be other arrangements. The cross-sectional shape of the pins 22 is not limited to a rectangle, but may be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com