Deflecting fence type square heat exchanger with waved tube

A baffle and wave tube technology, applied in the field of heat exchangers, can solve the problem that the shell-side structure cannot meet the design requirements of water-water heat exchange, cannot meet the technical requirements for the production and use of heat exchangers, and the structure of heat exchange tubes is complex. and other problems, to achieve the effect of good self-cleaning ability, inhibition of dirt deposition, and convenient and feasible installation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention is described in more detail below in conjunction with accompanying drawing example:

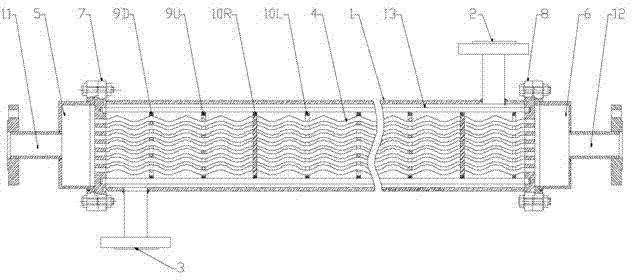

[0030] combine Figure 1~5 , the wave tube baffle grid type square heat exchanger of the present invention comprises a square shell 1, a shell-side inlet pipe 2, a shell-side outlet pipe 3, a heat exchange tube bundle 4, an upper head 5, a lower head 6, a tube sheet 7, 8. Transverse baffles 9D, 9U, longitudinal baffles 10R, 10L, tube-side inlet 11, tube-side outlet 12 and pull rod 13. The side inlet pipe 2 and the shell side outlet pipe 3 of the upper shell of the shell 1 adopt the form of side inlet and side outlet, and are installed at the two ends of the shell side close to the lower head 6 and the upper head 5, and flow in and out along the direction perpendicular to the shell. Out of the shell side space, the angle between the shell side inlet pipe 2 and the shell side outlet pipe 3 can be any angle according to the installation requirements, the pipe side i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com