Combustion device for circular combustion chamber in a gas turbine plant

一种环形燃烧室、燃气轮机的技术,应用在使用块状燃料和气态燃料的燃烧、使用液体燃料和气态燃料的燃烧、使用块状燃料和液体燃料的燃烧等方向,能够解决结构费事、燃烧器更换过程费时间等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

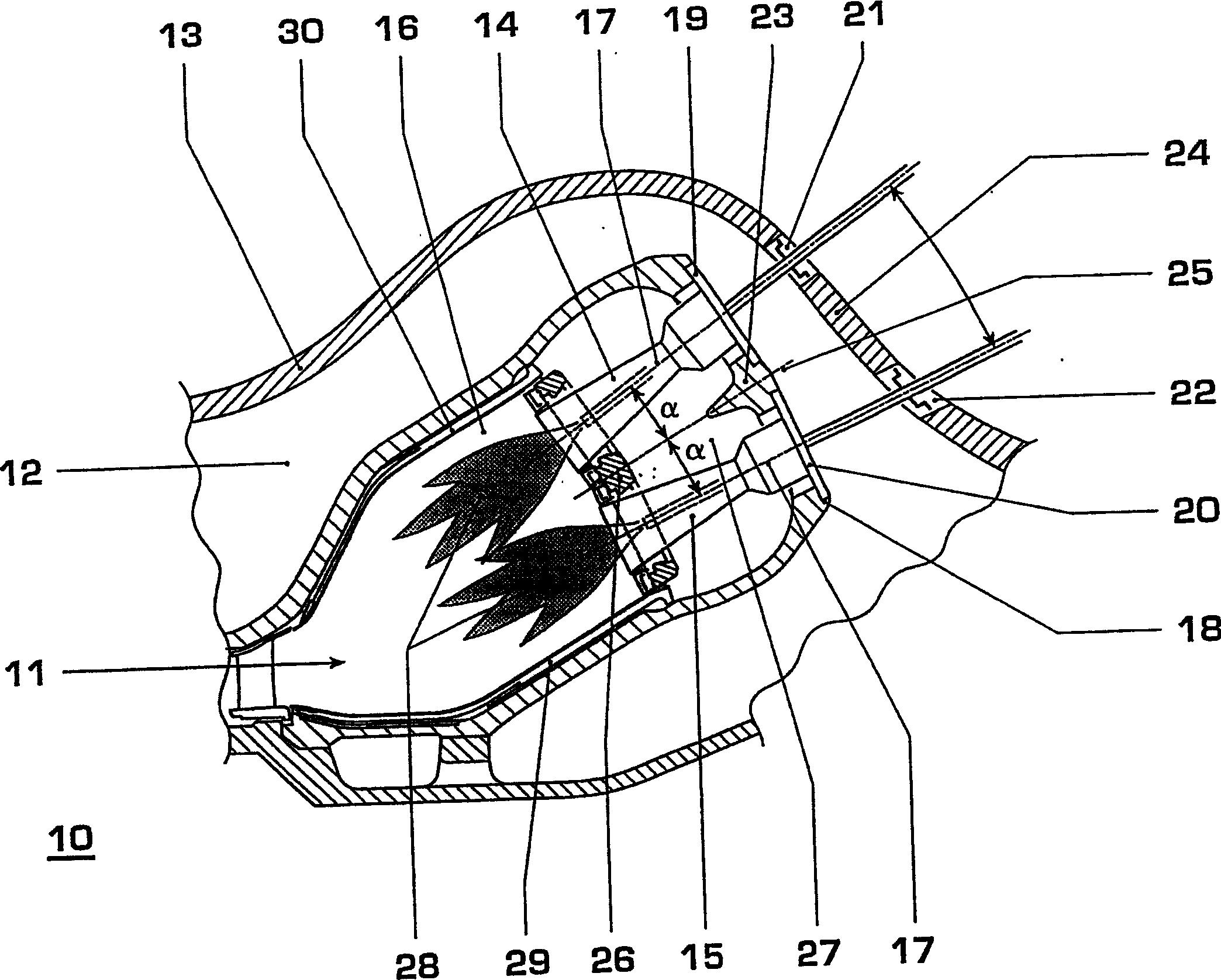

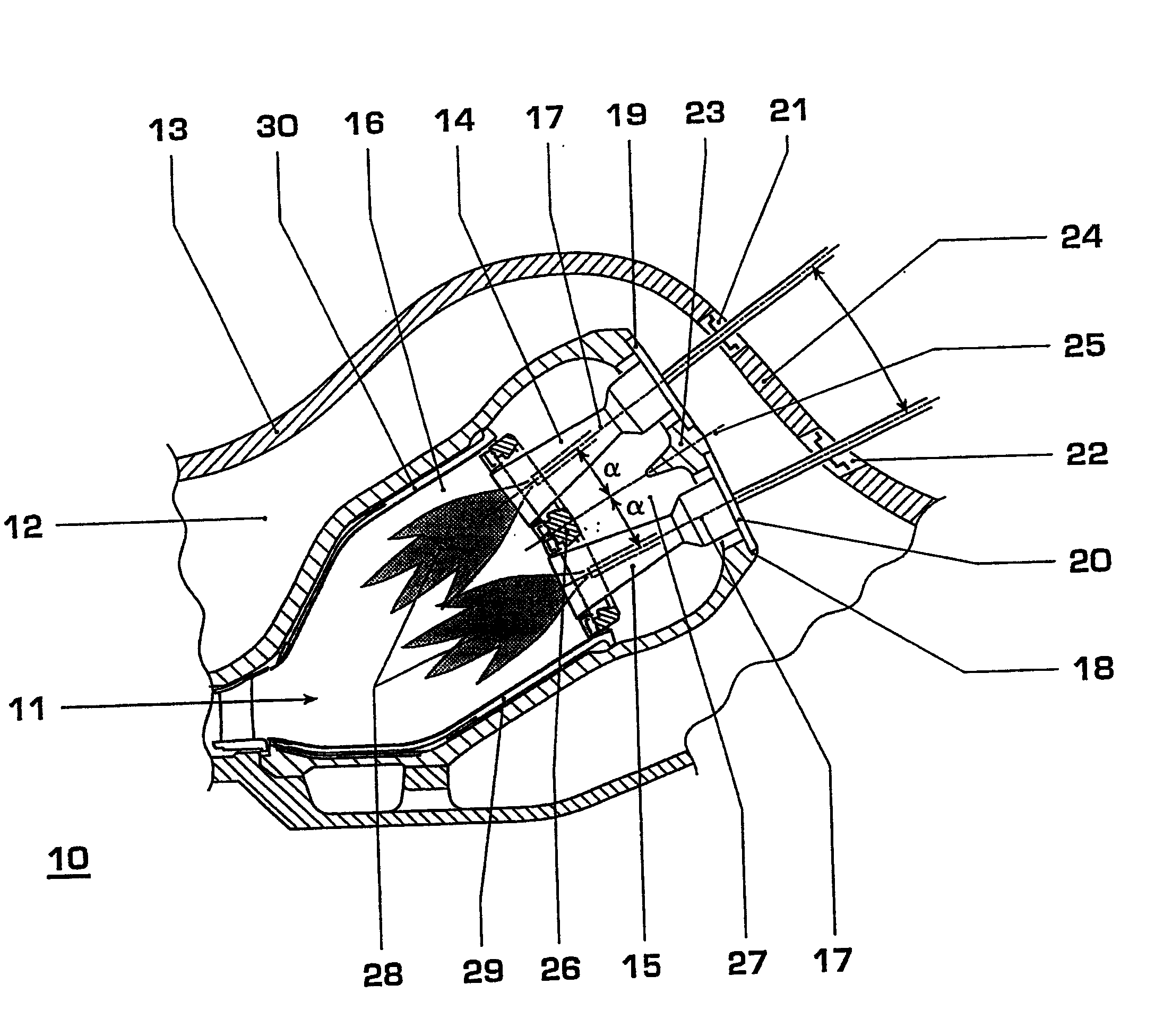

[0013] The drawing shows a section through a combustion chamber of a gas turbine with a burner arrangement according to a preferred embodiment of the invention. For the gas turbine 10, only a part above the axis of the gas turbine is shown, the gas turbine has a gas turbine outer casing 13, which surrounds a pressurized air space 12 filled with compressed air and a space between the compressor part and the turbine. Combustion chamber 11 between sections. The combustion chamber 11 is formed annularly with respect to the turbine axis. In its entry-side top chamber 27 are accommodated two rows of superposed burners 14 , 15 , which are designed in a known manner as double-cone burners and open into the combustion chamber 11 . The burners 14, 15 form a coaxial ring similar to that described in Figure 3 of EP-A1-0597138 (but with a different offset). The top chamber 27 is closed to the outside (towards the compressed air space 12 ) by a combustion chamber housing 18 . Correspondi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com