Microwave excited PVD coating equipment

A coating equipment and microwave emission technology, applied in the field of microwave excited PVD coating equipment, can solve the problems of damaging the quality of the coating layer, difficult to control the temperature, affecting the purity of the coating, and achieve the effects of improving the coating efficiency, high heating efficiency and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

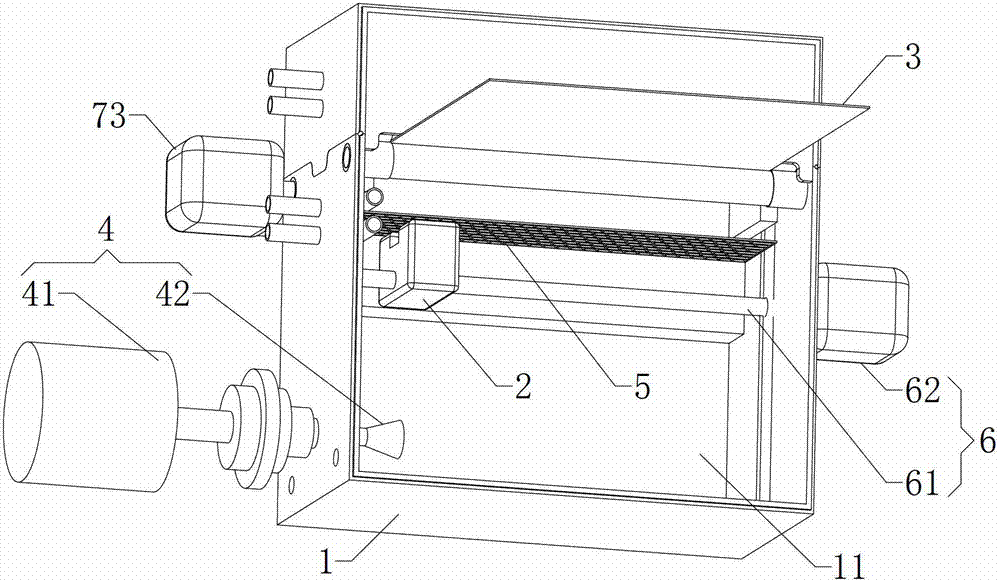

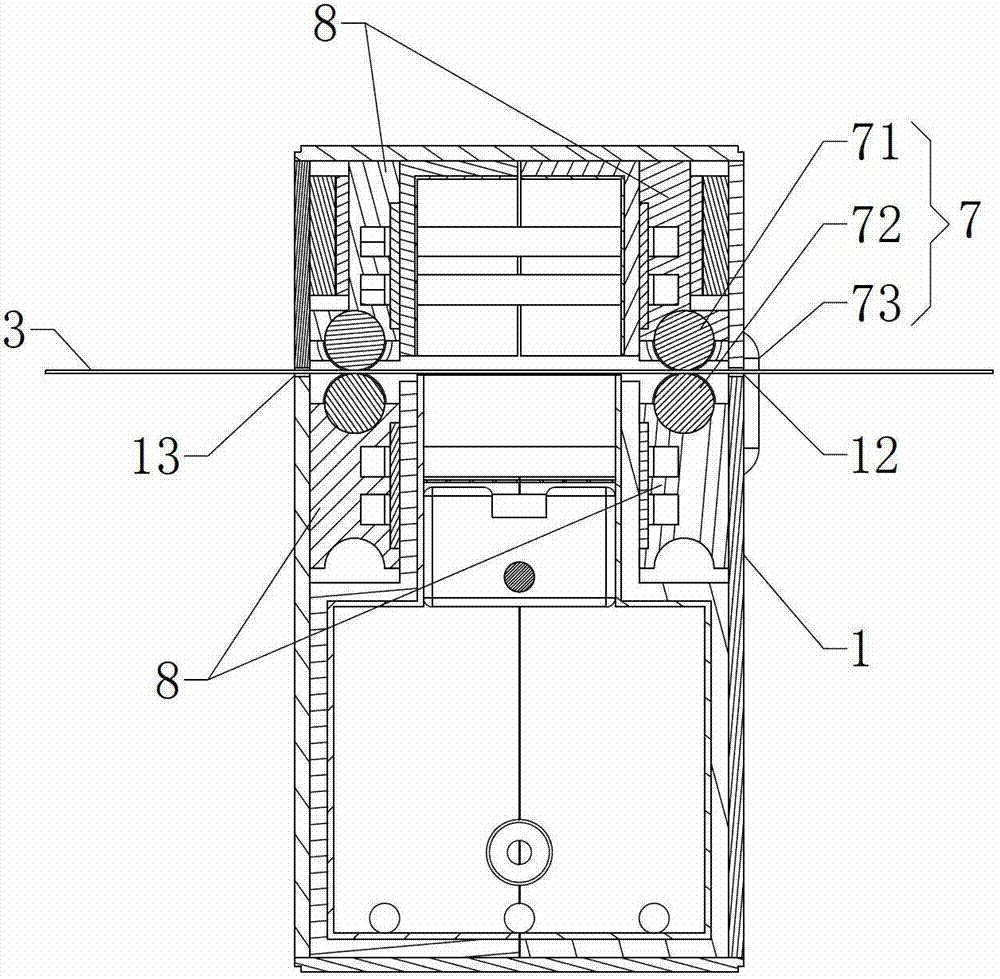

[0032] see image 3 , as a preferred embodiment of the present invention, four sets of the water-cooling heat sinks 8 are installed in the PVD cavity 11 .

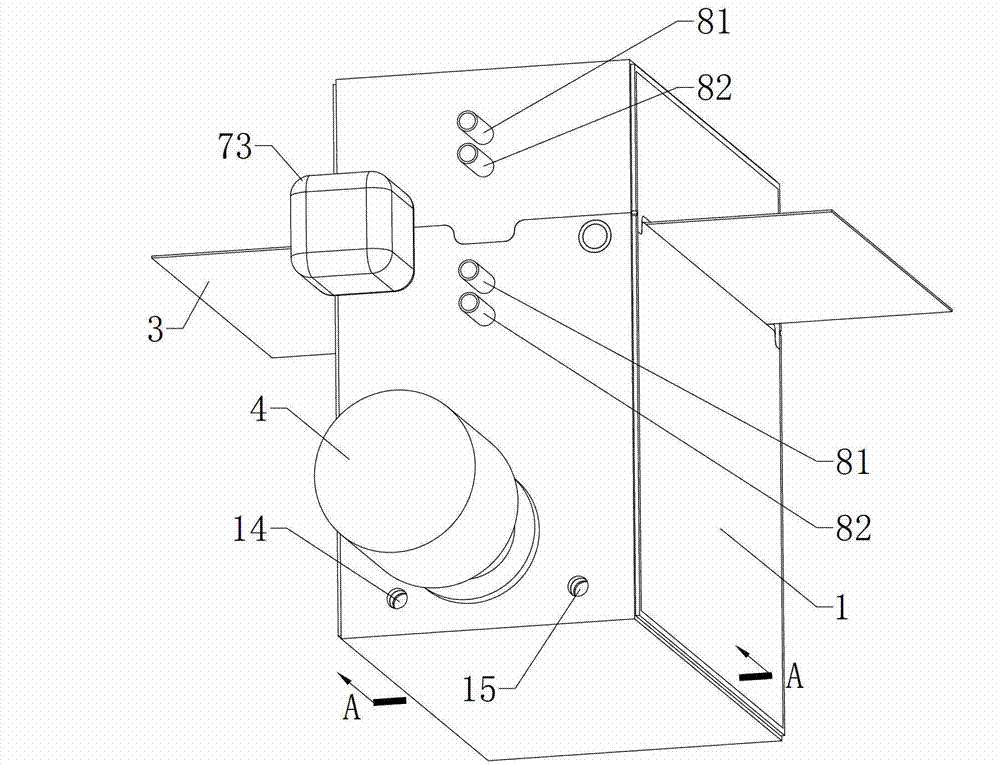

[0033] see figure 1 , the video surveillance device includes a video lens, and the casing 1 is provided with a lens installation hole 14 for installing the video lens.

[0034] The above-mentioned devices are all connected to the main controller, and the main controller can collect the feedback information from each device and control the working mode of each device.

[0035] The following describes the working process of the microwave-excited PVD coating equipment provided by the embodiments of the present invention:

[0036] First, the gas in the PVD cavity 11 is extracted;

[0037] Turn on the microwave generator 4 to heat the internal environment of the PVD cavity 11 and the target carrier boat 2 to the required temperature;

[0038] After the temperature measurement device measures the internal temperature of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com