Acrylate adhesive, protective film tape employing same and preparation method of acrylate adhesive

An acrylate and acrylate-based technology, applied in the field of protective film tape and its preparation, can solve problems such as unfavorable resource protection and environmental protection, failure to realize self-rewinding, violation of environmental protection development requirements, etc., to reduce user processes, Facilitate industrial production and save natural resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

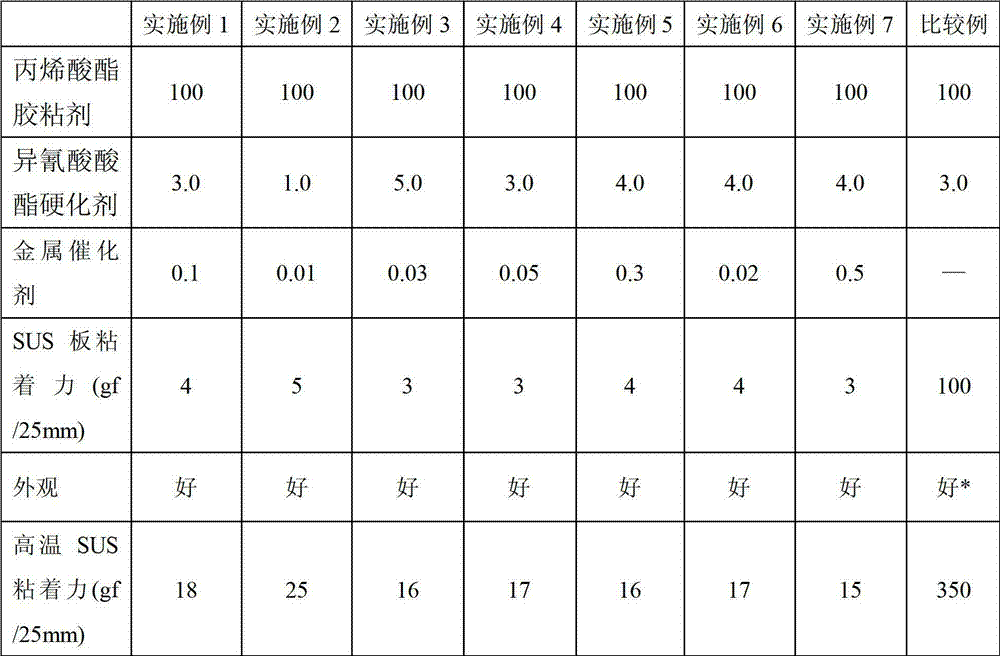

Embodiment 1

[0029] The acrylic pressure-sensitive adhesive is coated on one side of the base polyester film, as follows:

[0030] 1. Prepare the adhesive mixture, take 100 parts by mass of acrylic ester adhesive SK-1499M (produced by Soken Chemical Co., Ltd.), 3 parts by mass of isocyanate-based hardener HMDI, and 0.1 parts by mass of metal catalyst dilauric acid N-Butyltin, stir well after mixing, take a certain amount for coating, the coating thickness is 10μm, and dry after coating.

[0031] 2. The first section of the oven is set to 70°C for the removal of adhesive solvents, the second section is set to 120°C, and the third section is set to 130°C. These two sections are the curing stage.

[0032] 3. The drying time of the oven is 5min.

[0033] 4. After drying, cool to room temperature, then rewind and slit from the back to prepare protective film tape.

Embodiment 2

[0035] The acrylic pressure-sensitive adhesive is coated on one side of the base polyester film, as follows:

[0036] 1. Prepare the adhesive mixture, take 100 parts by mass of acrylic ester adhesive SK-1499M (Japan Soken Chemical Co., Ltd.), 1 part by mass of isocyanate-based hardener HMDI, and 0.01 parts by mass of metal catalyst tetraacetyl zirconium acetonate , Stir fully after mixing, take a certain amount for coating, the coating thickness is 7μm, and dry after coating.

[0037] 2. The first section of the oven is set to 70°C, which is used to drive the adhesive solvent, the second section is set to 100°C, and the third section is set to 120°C, these two sections are the curing stage.

[0038] 3. The drying time of the oven is 2min.

[0039] 4. After drying, cool to room temperature, then rewind and slit from the back to prepare protective film tape.

Embodiment 3

[0041] The acrylic pressure-sensitive adhesive is coated on one side of the base polyester film, as follows:

[0042] 1. Prepare the adhesive mixture, take 100 parts by mass of acrylic ester adhesive SK-1499M (Japan Soken Chemical Co., Ltd.), 5 parts of isocyanate hardener TDI, and 0.03 parts of metal catalyst dioctyl dineodecanoyl Oxygen tin, fully stir after mixing, take a certain amount for coating, the coating thickness is 10μm, and dry after coating.

[0043] 2. The first section of the oven is set to 80°C for the removal of adhesive solvents, the second section is set to 120°C, and the third section is set to 130°C. These two sections are the curing stage.

[0044] 3. The drying time of the oven is 5min.

[0045] 4. After drying, cool to room temperature, then rewind and slit from the back to prepare protective film tape.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com