Low temperature super-fast setting EVA (Ethylene Vinyl Acetate) coating

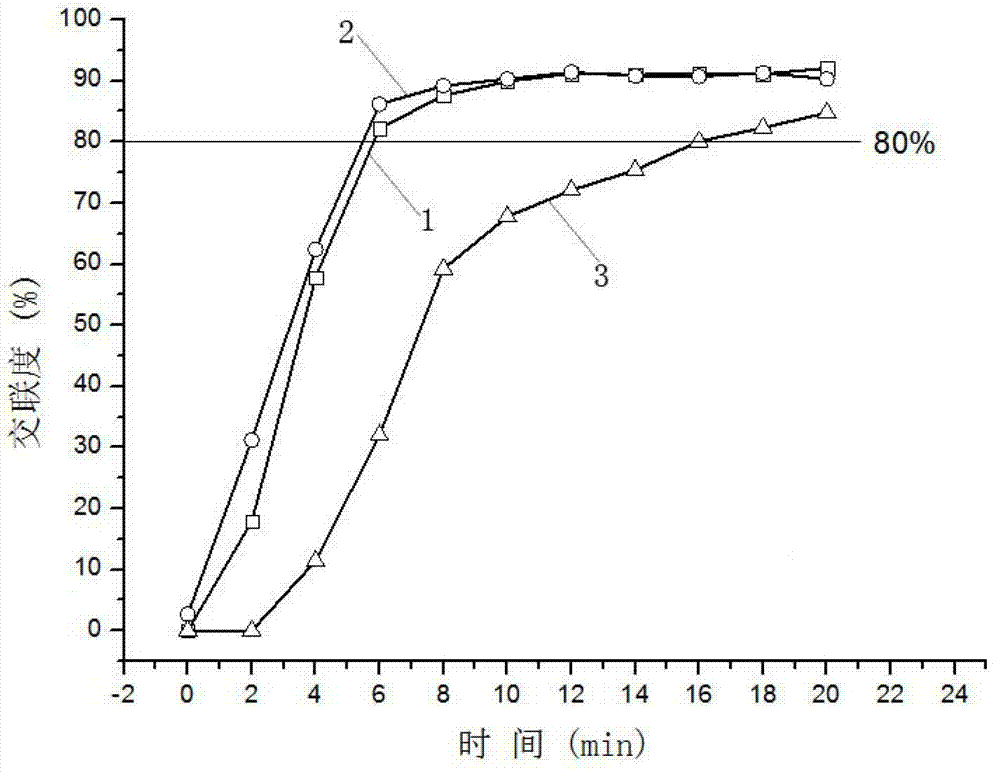

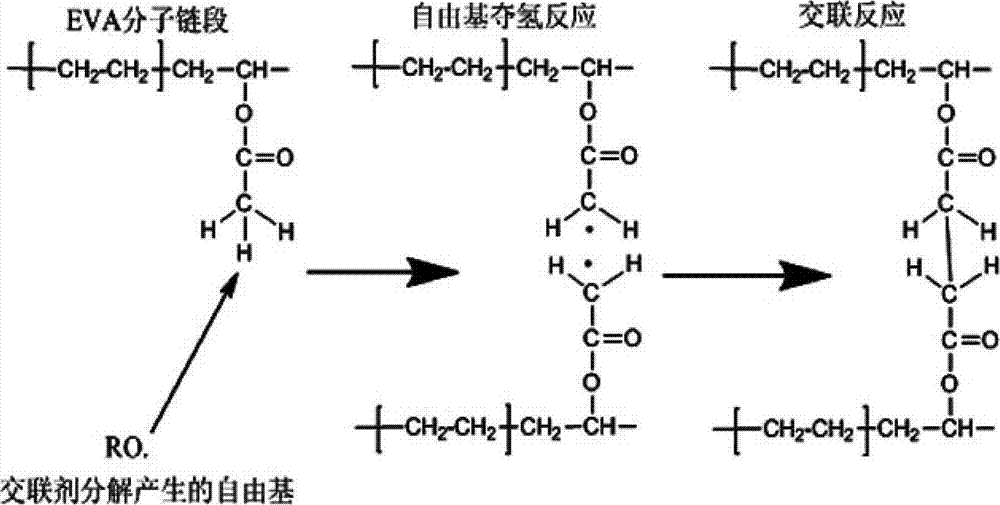

An ultra-fast, adhesive film technology, used in adhesives, film/sheet adhesives, non-polymer organic compound adhesives, etc. The aging resistance deteriorates and other problems, to achieve the effect of improving the crosslinking rate, taking into account the efficiency and process adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

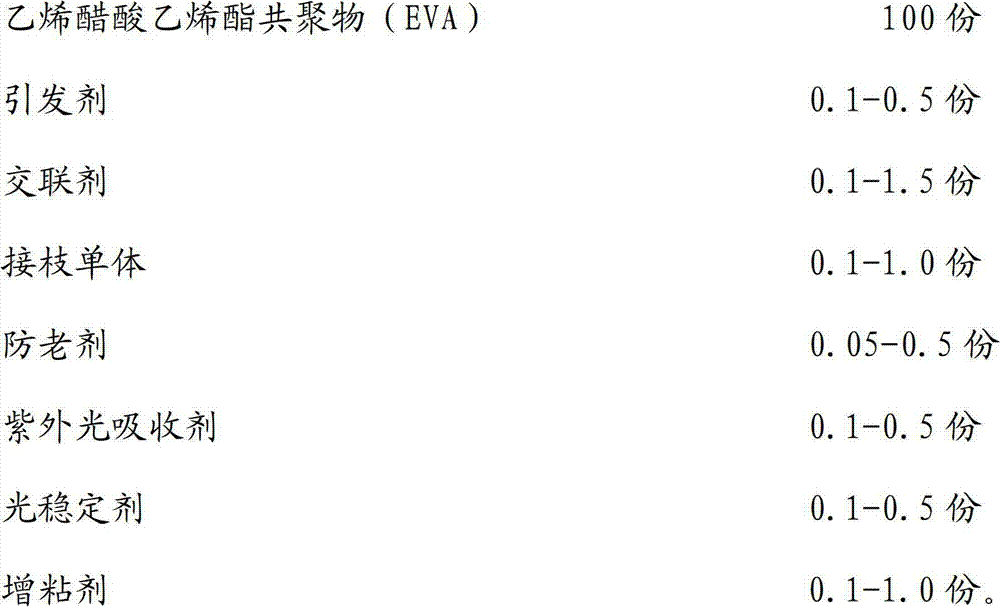

[0031] Add 0.1 mass parts of 1,1-di-tert-butylperoxycyclohexane (rapid initiator) to 100 mass parts of EVA raw materials with a mass content of 33% vinyl acetate and a melt index of 40 g / 10min, 1.0 mass parts tert-butylperoxycarbonate-2-ethylhexyl (slow crosslinking agent), 0.1 parts by mass of N,N'-m-phenylene bismaleimide (active monomer), 0.3 parts by mass of Tris(2,4-di-tert-butylphenyl)phosphite (antiaging agent), 0.4 parts by mass of 2-(2'-hydroxy-5'-methylphenyl)benzotriazole (ultraviolet absorber ), 0.2 parts by mass of bis-2,2,6,6-tetramethylpiperidinol sebacate (light stabilizer), 0.2 parts by mass of vinyltrimethoxysilane (tackifier), after mixing The feeder mixes evenly, puts it into the casting machine, and at 80°C, it is plasticized, extruded, stretched, drawn, and rolled to make an EVA film with a thickness of about 0.45mm.

Embodiment 2

[0033]In 100 parts by mass of vinyl acetate, the mass content is 33%, and the melt index is the EVA raw material of 40g / 10min. tert-butylperoxycarbonate-2-ethylhexyl (slow crosslinking agent), 0.3 parts by mass of N,N'-m-phenylene bismaleimide (active monomer), 0.05 parts by mass of (2,4-di-tert-butylphenyl) phosphite (antiaging agent), 0.5 parts by mass of 2-(2'-hydroxy-5'-methylphenyl)benzotriazole (ultraviolet light absorber) , 0.1 parts by mass of bis-2,2,6,6-tetramethylpiperidinol sebacate (light stabilizer), 0.1 parts by mass of vinyltrimethoxysilane (tackifier), after mixing The machine mixes evenly, puts it into the tape casting machine, and at 80°C, it is made into an EVA film with a thickness of about 0.45mm after plasticizing, extruding, stretching, pulling, and winding.

Embodiment 3

[0035] Add 0.5 mass parts of 1,1-di-tert-butylperoxycyclohexane (fast initiator) to 100 mass parts of EVA raw materials with a mass content of 28% vinyl acetate and a melt index of 15g / 10min, 1.0 mass parts 2,5-di-tert-butylperoxy-2,5-dimethylhexane (slow crosslinking agent), 1.0 parts by mass of N,N'-m-phenylene bismaleimide (active mono body), 0.5 parts by mass of tris(2,4-di-tert-butylphenyl) phosphite (antiaging agent), 0.1 parts by mass of 2-(2'-hydroxy-5'-methylphenyl)benzo Triazole (ultraviolet absorber), 0.5 parts by mass of bis-2,2,6,6-tetramethylpiperidinol sebacate (light stabilizer), 1.0 parts by mass of vinyltrimethoxysilane ( Tackifier), mixed evenly by a mixer, put into a casting machine, at 80 ℃, plasticized extrusion, stretching, traction, winding to make an EVA film with a thickness of about 0.45mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com