Method for preparing 1,4-dihydropyridine by taking acidic ionic liquid as catalyst

A technology of acidic ionic liquid and dihydropyridine, which is applied in chemical recovery, organic chemistry, etc., can solve the problems of production equipment corrosion, increase the inconvenience of process operation, etc., and achieve the effects of reducing pollution, easy operation, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

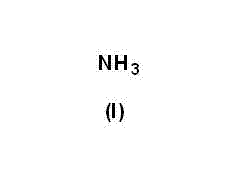

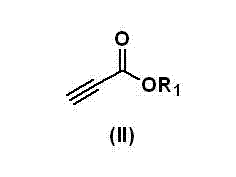

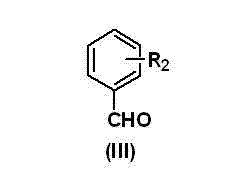

Method used

Image

Examples

Embodiment 1

[0030] Ammonium acetate (7.7g, 100mmol), methyl propiolate (16.8g, 200mmol) and benzaldehyde (10.6g, 100mmol) were thoroughly mixed, and 1-acetic acid-3-methylimidazolium chloride (1.1g) was used as a catalyst , reacted at 50° C. for 1.0 hour, cooled, poured into 30 ml of ice water, filtered with suction, washed, and dried to obtain 25.5 g of the product, with a yield of 93.5%.

Embodiment 2

[0032] Ammonium bicarbonate (7.9g, 100mmol), methyl propiolate (25.2g, 300mmol) and p-tolualdehyde (12.0g, 100mmol) were thoroughly mixed, and 1-acetic acid-3-methylimidazolium bromide (2.4 g) as a catalyst, reacted at 80°C for 0.5 hours, cooled, poured into 100 ml of ice water, filtered with suction, washed, and dried to obtain 25.6 g of the product with a yield of 89.2%.

Embodiment 3

[0034] Ammonium bicarbonate (7.9g, 100mmol), methyl propiolate (16.8g, 200mmol) and m-methoxybenzaldehyde (13.6g, 100mmol) were thoroughly mixed, and 1-acetic acid-3-methylimidazolium bromide ( 0.7 g) was used as a catalyst, reacted at 70° C. for 1.0 hour, cooled, poured into 150 ml of ice water, filtered with suction, washed, and dried to obtain 27.5 g of the product with a yield of 91.0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com