Method for preparation of methyl alkyl carbonate

A technology of methyl alkyl carbonate and dimethyl carbonate, applied in the field of preparation of methyl alkyl carbonate, can solve the problems of difficult catalyst recovery, high catalyst toxicity, high reaction temperature, etc., and achieve high conversion rate and selectivity , Environmental friendliness and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

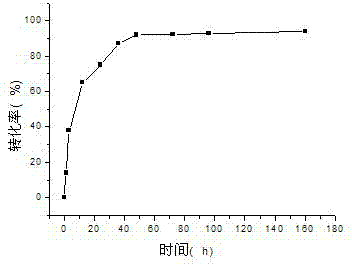

Embodiment 1

[0039] In the ionic liquid [Emim][PF 6 ] The reaction conditions of Candida antarctica lipase CAL catalyzed the reaction of dimethyl carbonate and butanol to prepare methyl butyl carbonate were as follows: the molar ratio of alcohol to ester was 1:12, the amount of enzyme was 12% of the reactant mass fraction, and the ionic liquid was 2 mL / g (based on ester weight, v / w), water content 1% (based on ester weight, w / w), and reaction temperature at 55°C, the reaction solution was taken regularly for analysis of methyl alkyl carbonate content. Take 50 μL of the reaction solution and centrifuge to separate layers, take 10 μL of the upper liquid sample, dissolve it in 290 μL cyclohexane, shake well, then add 300 μL of n-heptane (2 mg / mL) as an internal standard; take 1 μL of the sample for injection, and measure the reaction by gas chromatography The yield of methyl butyl carbonate in the product, the chromatographic column is SE-54 type. The specific test conditions are: the tempe...

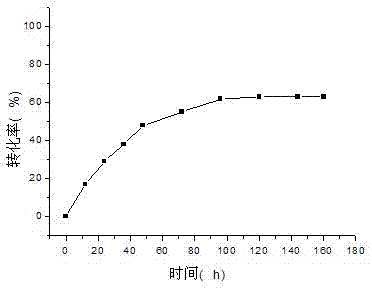

Embodiment 2

[0043] In the ionic liquid [Bmim][PF 6 ]Candida antarctica lipase CAL catalyzes the reaction of dimethyl carbonate and lauryl alcohol to prepare methyl lauryl carbonate. The reaction conditions are as follows: the molar ratio of alcohol to ester is 1:20, the amount of enzyme is 1% of the reactant mass fraction, and the ionic liquid is 2mL / g (based on ester weight, v / w), water content 1% (based on ester weight, w / w), reaction temperature 45°C, take the reaction solution regularly for analysis of asymmetric ester content. Take 50 μL of the reaction solution and centrifuge to separate layers, take 10 μL of the upper liquid sample, dissolve it in 290 μL cyclohexane, shake well, then add 300 μL of n-heptane (2 mg / mL) as an internal standard; take 1 μL of the sample for injection, and measure the reaction by gas chromatography The asymmetric ester yield in the product, the chromatographic column is SE-54 type. The specific test conditions are as follows: the temperature of the col...

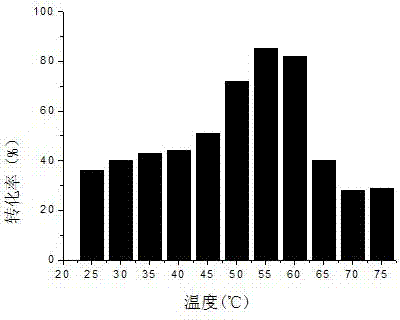

Embodiment 3

[0046] In ionic liquids [Emim][BF 4 ]Candida antarctica lipase CAL catalyzes the reaction of dimethyl carbonate and n-propanol to prepare methyl propyl carbonate. The reaction conditions are: the molar ratio of alcohol to ester is 1:12, the amount of enzyme is 8% of the reactant mass fraction, and the ionic liquid is 2mL / g (based on ester weight, v / w), water content 1% (based on ester weight, w / w), reaction temperature 25 ~ 75 ° C, reaction time 48 hours, the reaction solution was used for analysis of methyl propyl carbonate content. Take 50 μL of the reaction solution and centrifuge to separate layers, take 10 μL of the upper liquid sample, dissolve it in 290 μL cyclohexane, shake well, then add 300 μL of n-heptane (2 mg / mL) as an internal standard; take 1 μL of the sample for injection, and measure the reaction by gas chromatography The yield of methyl propyl carbonate in the product, the chromatographic column is SE-54 type. The specific test conditions are as follows: th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com