Method for preparing salvianolic acid A

A technology of salvianolic acid and salvia miltiorrhiza, applied in the field of salvianolic acid A preparation, can solve the problems of many conversion by-products, low yield of salvianolic acid A, uncontrollable conversion process, etc., and achieve the effect of improving the conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

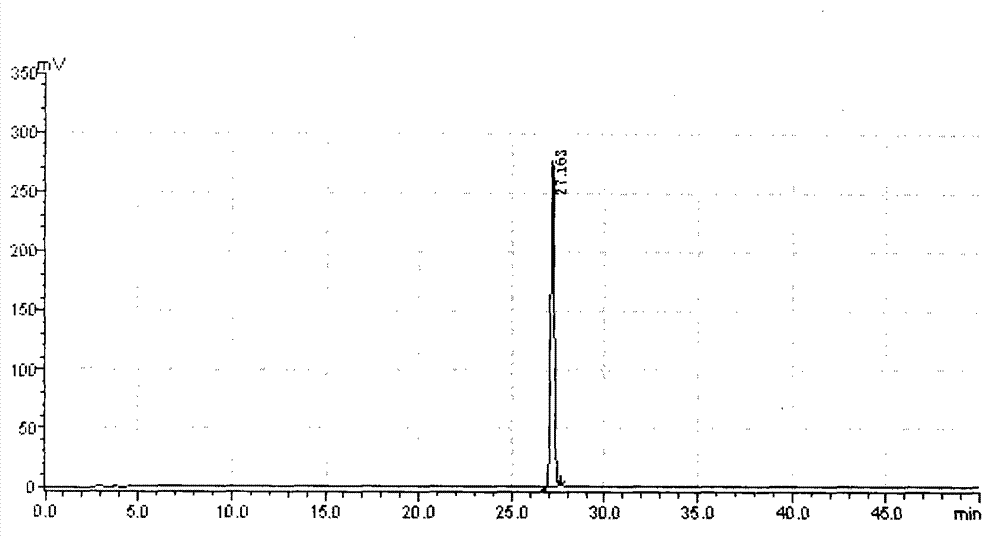

Image

Examples

Embodiment 1

[0059] Take Danshen medicinal material, crush it into 6-mesh granules, add 7 times the amount of 92°C water each time, warm soak and extract 3 times, and stir at a speed of 25 rpm, and warm soak and extract for 3 hours each time; the extract is concentrated under reduced pressure to relative Density 1.20 (60°C), add ethanol to make the alcohol content at 70%, let it stand, filter, the filtrate is decompressed to recover ethanol and concentrate until it has no alcohol smell; add water to dilute to contain salvianolic acid B20mg per 1ml, use 10% for aqueous solution Adjust the pH to 4.0 with sodium hydroxide, add 0.5% ZnCl 2 As a catalyst, heat and transform at 120°C for 4 hours, adjust the pH value of the transformation liquid to 2.5 with 20% phosphoric acid, centrifuge, concentrate the supernatant under reduced pressure to contain 3 mg of salvianolic acid A per 1 ml, and perform HPD-100 macroporous resin column chromatography For separation, the ratio of the loading amount of ...

Embodiment 2

[0061] Take Salvia miltiorrhiza, cut into decoction pieces, add 8 times the amount each time, soak in water at 90°C for 3 times, stir at a speed of 20 rpm, and extract with warm soaking for 2.5 hours each time; the extract is concentrated under reduced pressure to a relative density of 1.18 (60 ℃), add ethanol to make the alcohol content at 75%, let it stand, filter, and the filtrate reclaims ethanol under reduced pressure and concentrates to no alcohol smell; add water to dilute to contain salvianolic acid B15mg per 1ml, adjust the aqueous solution with 10% potassium hydroxide pH to 4.0, add 0.6% FeCl 3 As a catalyst, heat conversion at 120°C for 3.5 hours, adjust the pH value of the conversion liquid to 2.5 with 15% hydrochloric acid, centrifuge, concentrate the supernatant under reduced pressure to contain 5 mg of salvianolic acid A per 1 ml, pass through HPD-100 macroporous resin column layer Analysis and separation, the ratio of the loading amount of salvianolic acid A to...

Embodiment 3

[0063] Take the Danshen medicinal material, crush it into particles with a diameter of about 2mm, add 9 times the amount each time, soak in water at 85°C for 2 times, and stir at a speed of 30 rpm, and extract with warm soaking for 3.5 hours each time; the extract is concentrated under reduced pressure to a relative density 1.14 (60°C), add ethanol to make the alcohol content at 75%, let it stand, filter, and recover the ethanol from the filtrate under reduced pressure and concentrate until there is no alcohol smell; add water to dilute to 18mg per 1ml of salvianolic acid B, and use 10% carbonic acid in the aqueous solution Adjust pH to 5.2 with sodium, add 0.6% AlCl 3 As a catalyst, heat conversion at 123°C for 4.5 hours, measure the pH value of the conversion liquid to 2.8 with 15% nitric acid, centrifuge, concentrate the supernatant under reduced pressure to contain 6 mg of salvianolic acid A per 1 ml, pass through HPD-100B macroporous resin column layer Analysis and separa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com