Preparation method of graphene-nanosheet-reinforced alumina ceramic

A technology of graphene nanosheets and alumina ceramics, applied in the field of preparation of alumina ceramics, can solve the problems of poor product density, phase change whiskers and particle toughening effects are not particularly obvious, and fiber toughening operation engineering is complicated. , to achieve the effect of good product performance, low cost and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

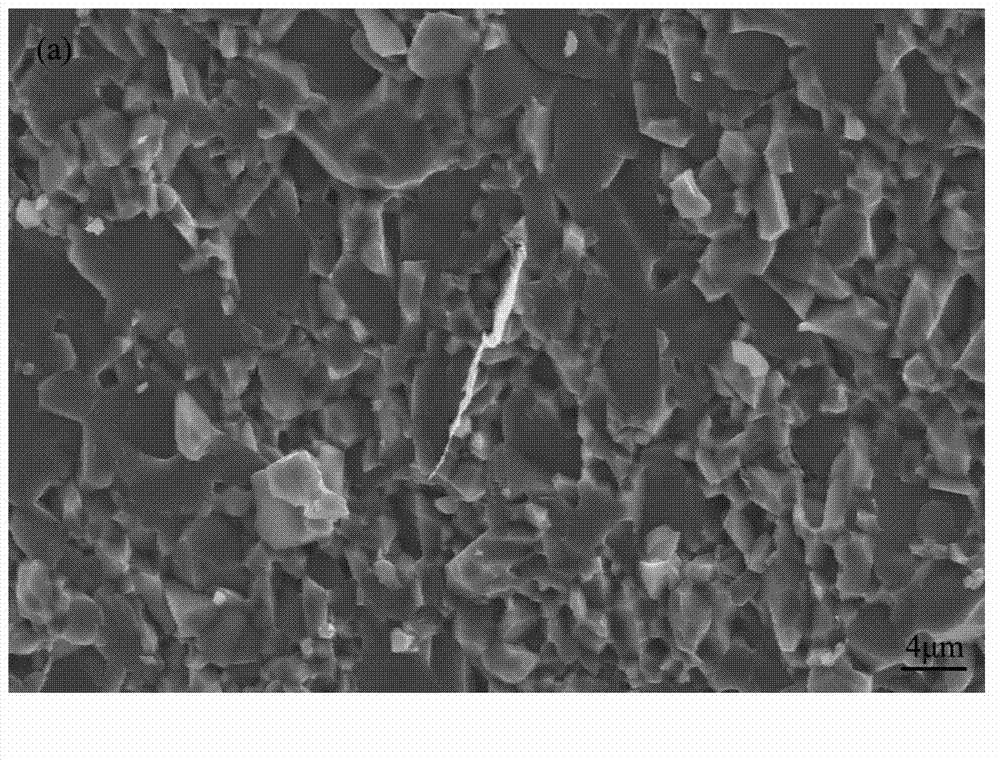

[0027] Alumina composite ceramics were prepared by hot pressing and sintering with graphene nanosheets as the reinforcing phase. Weigh 34.965g of alumina powder with a balance, put 245g of alumina balls into a planetary ball milling tank, add 150ml of absolute ethanol as the ball milling medium, and ball mill at 300r / min for 8 hours at room temperature to obtain the required alumina slurry; Then weigh 0.035g graphene nanosheets with a balance, dissolve 0.007g dispersant sodium naphthalenesulfonate in 30ml distilled water with pH=10 to form an aqueous solution, place in an ultrasonic cleaner, and ultrasonically 1 hour; then the graphene The aqueous solution is added to the alumina slurry in the planetary ball mill tank, and the ball mill is 300r / min at room temperature for 8 hours to form a mixed powder; the mixed powder after ball milling is placed in a graphite mold, and then the graphite mold is placed in a multifunctional sintering In the furnace, the temperature was raised...

Embodiment 2

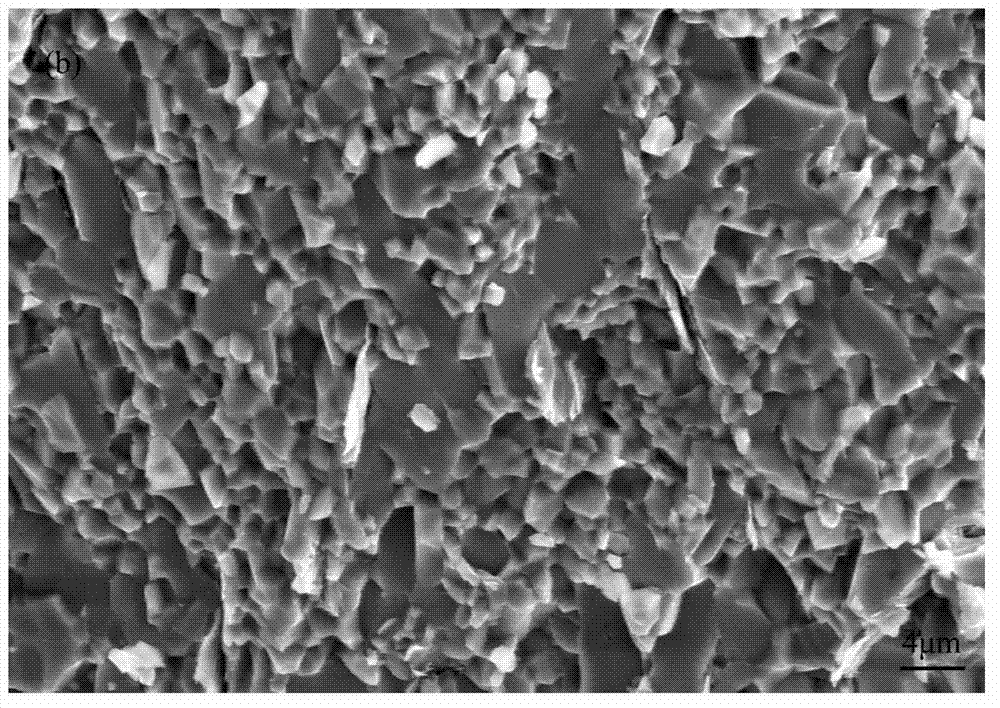

[0029] Alumina composite ceramics were prepared by hot pressing and sintering with graphene nanosheets as the reinforcing phase. Weigh 34.93g of alumina with a balance, put 245g of alumina ball milling balls into a planetary ball milling tank, add 150ml of absolute ethanol as the ball milling medium, and ball mill at 300r / min for 9 hours at room temperature to obtain the required alumina slurry; Weigh 0.07g of graphene nanosheets with a balance, dissolve 0.014g of dispersant sodium naphthalenesulfonate in 35ml of distilled water with pH=10 to form an aqueous solution, place it in an ultrasonic cleaning device, and ultrasonicate for 2 hours; then the graphene aqueous solution Add to the alumina slurry in the planetary ball mill tank, and ball mill at room temperature for 9 hours at 300r / min to form a mixed powder; put the mixed powder after ball milling into a graphite mold, and then place the graphite mold in a multifunctional sintering furnace In the process, the temperature ...

Embodiment 3

[0031] Alumina composite ceramics were prepared by hot pressing and sintering with graphene nanosheets as the reinforcing phase. Weigh 34.825g of alumina with a balance, put 245g of alumina ball milling balls into a planetary ball milling tank, add 100ml of absolute ethanol as the ball milling medium, and ball mill at 300r / min for 8.5 hours at room temperature to obtain the required alumina slurry; Weigh 0.175g of graphene nanosheets with a balance, dissolve 0.035g of dispersant sodium naphthalenesulfonate in 90ml of distilled water with pH=12 to form an aqueous solution, place it in an ultrasonic cleaner, and ultrasonicate for 1.5 hours; then the graphene aqueous solution Add it to the alumina slurry in the planetary ball mill tank, and ball mill it at 300r / min for 8.5 hours at room temperature to form a mixed powder; put the mixed powder after ball milling into a graphite mold, and then place the graphite mold in a multifunctional sintering furnace In the process, the temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com